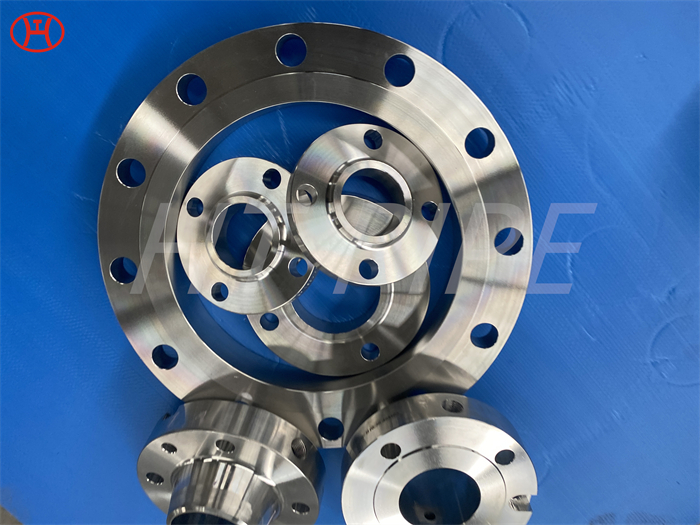

Haɗin flangen yana da matsalar lalacewa, kuma ya kamata a sarrafa adadi mai zurfi a cikin tsari mai izini na tsari.

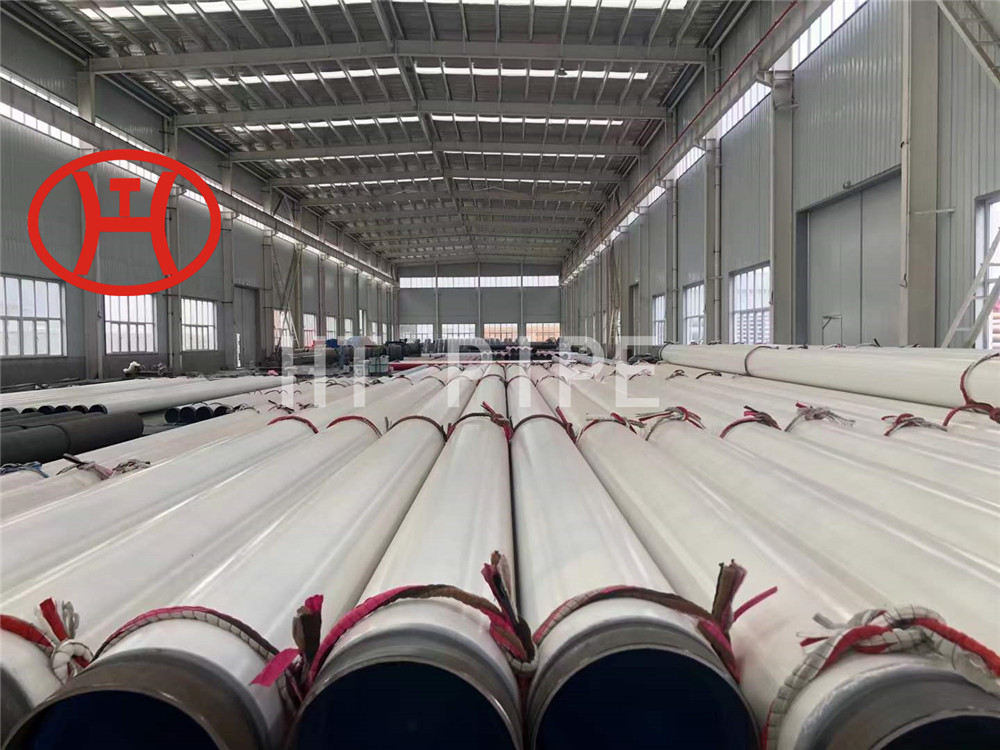

Alloy Karfe bututu yana da sashen m kuma ana amfani dashi sosai azaman bututun ruwa don jigilar ruwa, kamar mai, gas, gas, ruwa da wasu m kayan. Idan aka kwatanta da ƙarfe mai ƙarfi kamar ƙugiya, alloy karfe bututu ne mai nauyi tare da karfin iri ɗaya da ƙarfin iko.Harrafa 36 mara kyau K93600An kera tare da manyan ayyukan sunadarai na 1-1.50% na chromium, carbon, 0.44-0.65 na molybdenum, 0.50-1% na sulfur. Astm A335 Ciwi mara laushi yana da ƙananan burbon carbon, manganese, phosphorous, da silicon.

Astm A335 Karfe M Karfe Chrome bututu an tsara don tsayayya da lalata a cikin mahalli daban-daban. Suna da kyawawan juriya na iskar oxidation kuma suna iya yin kyau a cikin matsanancin matsi da yanayin zafi. A cikin NBR 5603, P11 Chrome bututun sanyi sanyi mirgine ko tsarin zane mai sanyi na iya faruwa bayan tsari na farko-rolling na farko. Wadannan bututun na iya zama zafi da aka bi da su ko kuma a jera cututtukan ruwa a yanayin zafi har zuwa 1200 digiri, da sauran masana'antu, da sauransu petrocal masu samar da A335 P11 a Indiya. An yi burinmu na samar da mafi kyawun samfuran a mafi yawan kudaden.

Sindhi

Ana amfani da bututun mai da anko K11597 a cikin tsarin matsin lamba da aikace-aikace daban-daban. Wadannan bututun suna da kyakkyawan ƙarfi da ƙarfi don kare su daga leaks da karya. The alloy Karfe Sa 335 p11 An tsara bututun matsin lamba tare da karfin da ba ya ƙasa da ƙarancin shekaru 30 na ksi. Wadannan bututun, kamar ASM A335 sa na P11, bututun mayoy na iya zama da elongated da mafi ƙarancin 20% -30%.

alloy karfe bututun bututu mara kyau

| www.oeppe.com | Samu farashin | SarWaniya | Alloy bututu | Raba: | Carsican | » | |

| 0.30 – 0.60 | 0.44 – 0.65 | A baya: | 0.05 – 0.15 | A baya: | 1.00 – 1.50 | 0.50 – 1.00 |

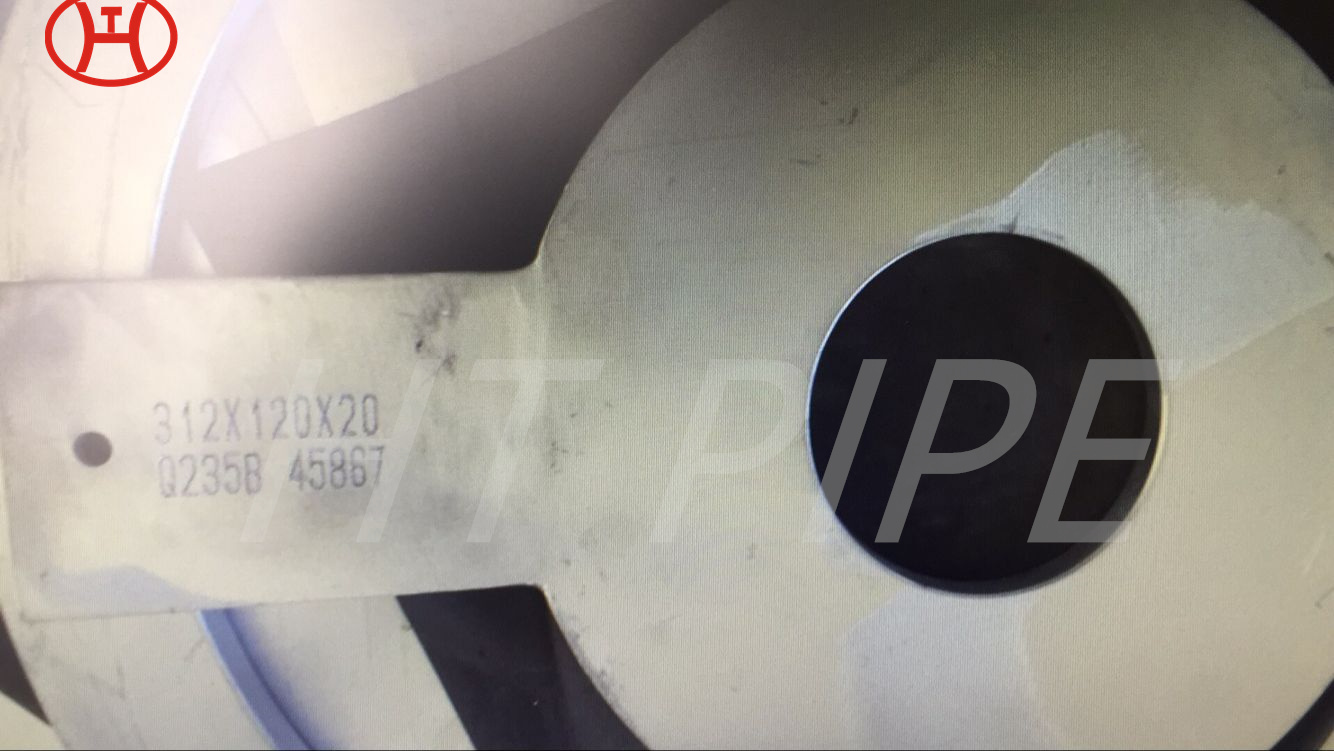

Invar 36 od od: 0.2-6mm, wt: 0.02-22mm

| A335 p11Aloy bututu | Kurdawa (Kurmanji) | Bakin ƙarfe |

| Wadatacce | Silicon | Ainihin gawayi |