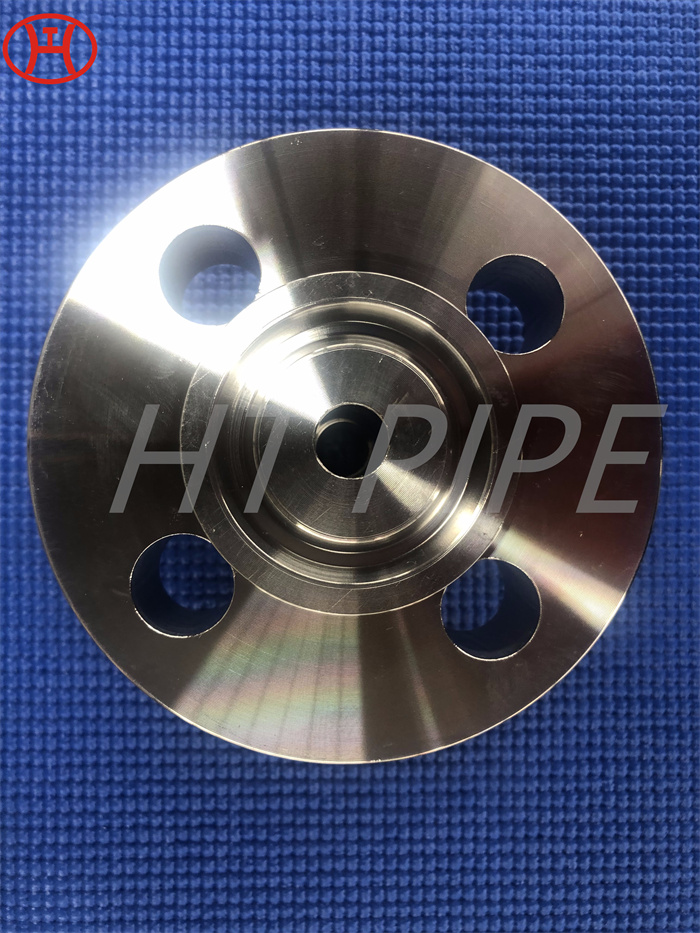

Yawancin Ansani ani \ / Asme ƙa'idodi amfani da kayan da aka ƙirƙira ko jefa su samar da sifarsu a matsayin flanges makafi.

Duk zanen gado molybdenum karfe sunyi magani da zafi da yawa a cikin karfe: kayan kwalliya, mangaloum, nitrogen, aluminum, titanium da Zirconium. Aljihun A387 dole ne suyi amfani da samfurin A387 (an lasafta su a cikin takardar shaidar gwaji na MTC ko kayan abu don ƙarfi na tenerile, ƙarfi da elongation.

Sa 387 gr 11 M karfe ana amfani dashi a cikin kewayon zazzabi (316 ℃ -593 ℃). Abubuwan da ke yawan zafin jiki da yawa na har yanzu suna sha'awar paricular ta yanzu, har ma da Trend na yanzu zuwa aikace-aikace tare da buƙatun CVN. Sa 387 Gr 11 Karfe M Karfe annan silicon, low silicon, low sulful, da lokaci-lokaci ya samar da Q & T don bayar da mafi girman matakan.

Sulfur

Alloy Karfe wanda ke da ƙarfe wanda ya rigaya da abubuwa da yawa a cikin duka adadin tsakanin 1.0% da 50% ta hanyar haɓaka kadarorinta na kayan aikinta. Alloy Maske sun lalace zuwa ƙungiyoyi biyu: low alloy steves da kuma suttely stecks. Bambanci tsakanin su biyun an yi jayayya. Smith da Hashemi sun ayyana bambanci a 4.0%, yayin da Degarmo, et al., Ayyana shi da 8.0%. [1] Mafi yawanci, kalmar "alloy karfe" yana nufin ƙananan kishin ƙasa.Sinanci (na gargajiya)Firayim mai zafi ya yi birgima

Sulfur

Abubuwan da aka yi a320 Gr L7 za su sha kashi a kan kwastomomi masu zuwa - Gwajin Tasirin Tefen da kuma wahalar gwaji gwargwadon ƙamus na injiniya na A320. Dokar A320 GR L7 HDG ta rufe maki da yawa na bakin karfe ciki har da Austenitic da ferritic bakin karfe.

Sulfur

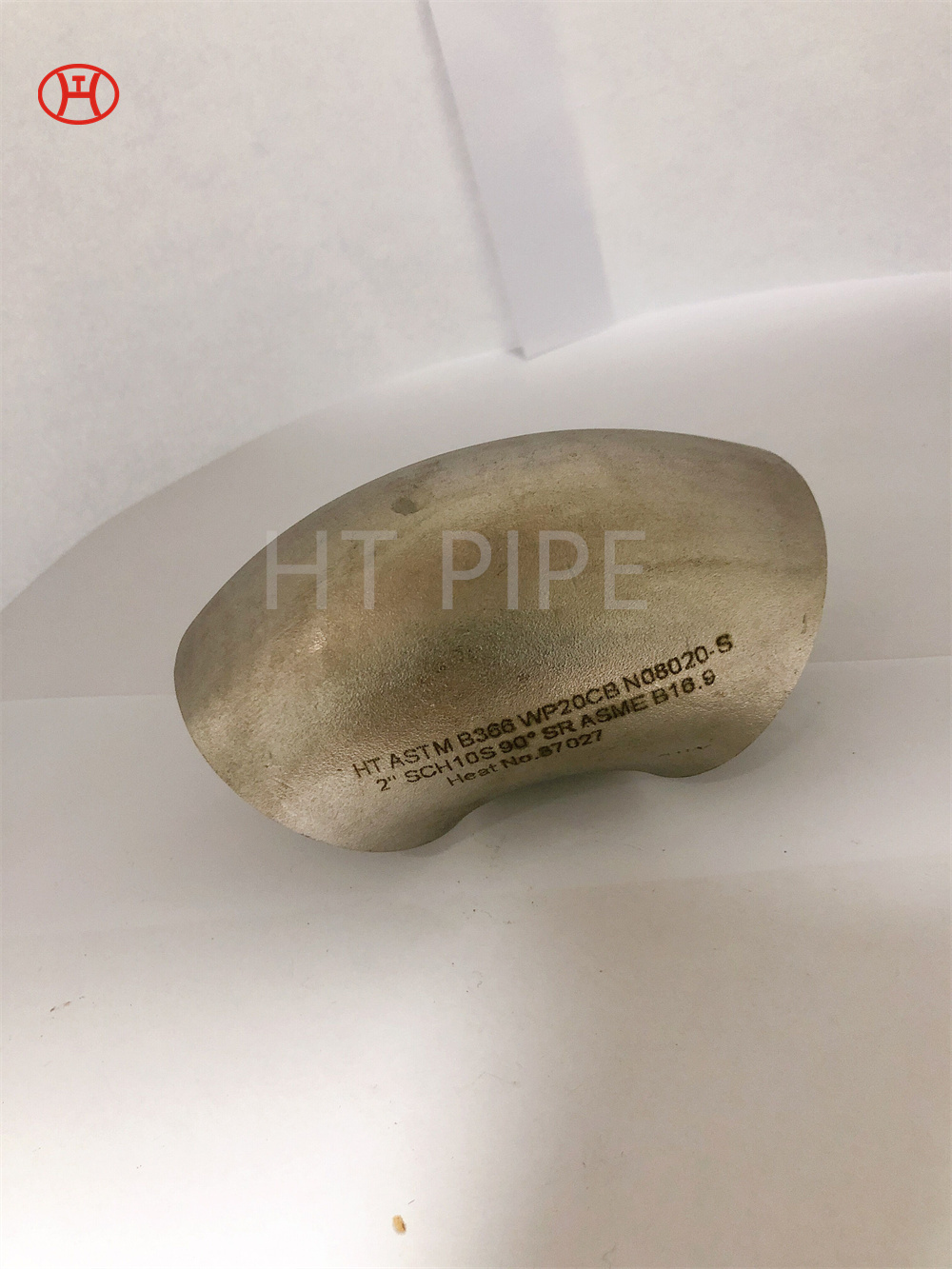

Pipoy Meloy MIPIES da TUBE

Tsawon 0 ~ 12m ko kamar yadda kuke buƙata

Nisa 0 ~ 2500mm ko kamar yadda kuke buƙata

A387 \ / sa387 alloy karfe farantin sinadarai:

Tsari zafi \ / sanyi yi birgima

Kauri 0.3 ~ 1200m ko kamar yadda kuke bukata

Alloys M Karfe Sa 182 F9 yana da kyakkyawan ƙarfi da kuma kyakkyawan lalata juriya a babban yanayin zafi.

Girman OD: 1 \ / 2 "" ~ 48 "

Sulfur

| A387 \ / Sa387 | Silicon | 0.5 max | Saura 22 | 0.15 Max | 0.55 Max |

| M | 1.05 Max | 1.05 Max | 0.04-0.17 | 0.04-0.17 | 0.04-0.15 |

| Manganese | 0.25-0.66 | 0.25-0.66 | 0.35-0.73 | 0.35-0.73 | 0.25-0.66 |

| Mai phosphus | 0.035 | 0.030 | 0.035 | 0.035 | 0.035 |

| Czech | 0.030 | 0.030 | 0.035 | 0.035 | 0.035 |

| Aji 1 | Chromium | Incoloy | 0.44-0.86 | 0.13-0.45 | Class 2 |

| M | 3.9-6.1 | 7.9-10.1 | 0.94-1.56 | 0.74-1.21 | 1.88-2.62 |

| Molybdenum | 0.40-0.7 | 0.85-1.15 | 0.40-0.7 | 0.4-0.65 | 0.85-1.15 |

| Gida | A 387 aji 5 | A 387 aji 9 | A 387 aji 11 | A 387 aji 12 | A 387 aji 22 | |||||

| Bincike | E-mail: | Bincike | E-mail: | Bincike | E-mail: | Bincike | E-mail: | Bincike | E-mail: | |

| Tenarfafa tena (ksi) | 60-85 | 75-100 | 60-85 | 75-100 | 60-85 | 70-90 | 50-80 | 60-85 | 60-85 | 75-100 |

| Tenerile ƙarfi (MPa) | 415-585 | 515-690 | 415-585 | 515-690 | 415-585 | 485-620 | 380-550 | 415-585 | 415-585 | 515-690 |

| Sinanci (a sauƙaƙe) | 30 | 45 | 30 | 45 | 35 | 45 | 33 | 40 | 30 | 45 |

| Samar da ƙarfi (ksi) | 205 | 310 | 205 | 310 | 240 | 310 | 230 | 275 | 205 | 310 |

| Elongation a cikin 200mm (%) | 19 | 18 | 18 | 19 | ||||||

| Elongation a cikin 50mm (%) | 18 | 18 | 18 | 18 | 22 | 22 | 22 | 22 | 18 | 18 |

| Rage yanki a% | 45 | 45 | 45 | 45 | 45 | 45 | ||||