Na-emepụta ọkọlọtọ ASME B36.10 Asme B36.37

Alloy 20 (alloy 20) bụ Aulenitic Almenitic nke dị iche iche mepụtara iji guzogide corrosic acid acid. Ọ nwere nguzogide nduru sọlfọ; O nwere iguzogide siri ike na phosphoric acid, nitric acid na gburugburu gburugburu chloride, corroside nrụgide, na-etinye corrosion na corrosion. Ya mere, alloy 20 nwere aha nke mgbochi corrosion allosion. Ọ nwere ọtụtụ ngwa dị iche iche: Chemical, nri, ọgwụ, ọgwụ ike na ụlọ ọrụ plastik ga-eji ya. N'ihi na nguzogide corrosion na corrosion chloride, nsogbu na-agbawa nsogbu nsogbu, wdg, alloy 20 na-ejikarị.

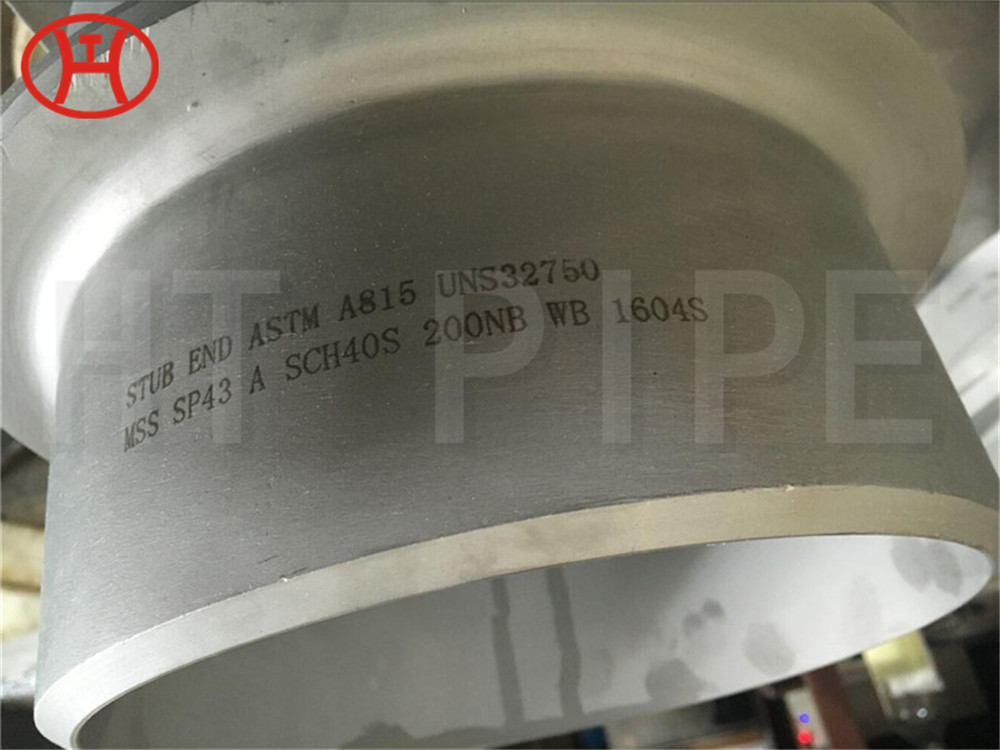

S32205 bụ igwe anaghị agba nchara na steepụ nke igwe anaghị agba nchara. Duxlex na-ejikwa 28% chromium, 2.5% molybdenum na 4.5% nickel-nitrogen alloy. O nwere ike dị elu, mmetụta dị mma siri ike na nke ọma na mpaghara nrụgide obodo na-eguzogide. Ike ike nke beax na-enweghị isi bụ ugboro abụọ nke ndị na-adịghị ọcha na-eme ka ndị na-eme ihe na-eme ihe mgbe ha na-emebe ihe mgbe 316L. Alloy a kacha adabara maka iji ya na -50¡0F \ / + 600¡Ã0FE. Maka ngwa na mpụga ọnọdụ okpomọkụ a, enwere ike ịtụle alloy a, mana enwere ụfọdụ adịghị mma, ọkachasị mgbe etinyere ya na owuwedoro. Duplex na-enweghị igwe nwere ike okpukpu abụọ tụnyere igwe anaghị agba nchara, ndị na-ese ihe nwere ike belata ogo ya tụnyere 316l na 317L. Alloy 2205 kacha adabara maka iji ọnọdụ okpomọkụ \ / +ÃãÃf, ma enwere ike iji ọnọdụ dị ala n'okpuru mmachi siri ike (karịsịa maka owuwu enyere).

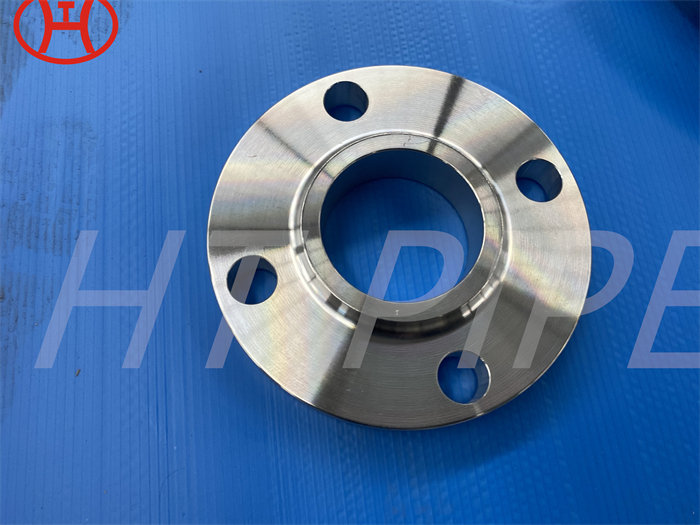

Alloy na igwe anaghị agba nchara dị mma maka ngwa dị elu, ahọpụtara maka ịdịte ha, ma na-eguzogide nguzogide. We supply materials for a variety of industries such as: food processing, pharmaceuticals, energy, plant maintenance, and oil and gas exploration.

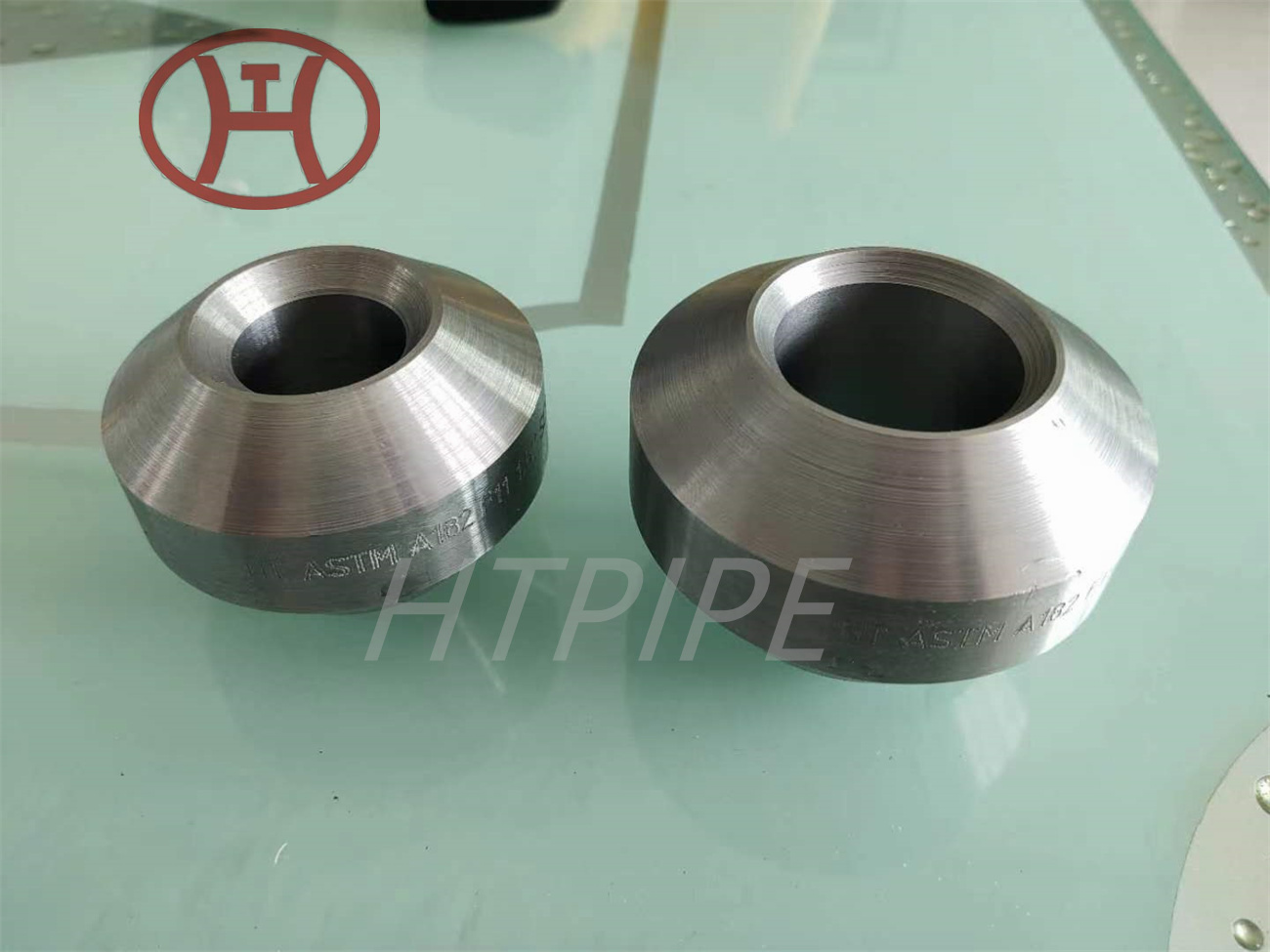

Ihe omumu nke ato, carbon steel na-acha uhie uhie, ASTM F65 SEL na-ewu ewu Elb, ASTM A182 p32750 Studing Bolt bụ akwụkwọ akụkọ na nhazi. Ha na-ere nke ọma n'ụlọ na mba ọzọ, ma nabata ọtụtụ ndị ọrụ na-anabata ya. Site na imubanye ezigbo ọrụ, anyị na-atụ anya itinye aka na uto ọhụrụ mmepe nke idobe gburugburu, na-enyere aka ọha na mkpa nke ike mmadụ. Ka ọ dị ugbu a, anyị na-emekwu mgbalị iji tinye aka na ọhụrụ dị mma, na-enwe olileanya ịrụpụta usoro ọgwụgwọ ọhụrụ nke mmepe ụlọ ọrụ ahụ. Ka ụlọ ọrụ na-eche banyere teknụzụ, ụlọ ọrụ na-akwụghachi ndị ahịa na ngwaahịa na ọrụ ndị ka mma. Ngwá ọrụ dị elu, Nhazi Ọkachamara, teknụzụ mmepụta dị mma, sistemụ nkwari zuru oke na ọrụ ahịa na-akwụ ụgwọ ọ bụla.

Asme SE Li31 p91 p91 p91 p91 p91 p91 nchara pipe nwekwara ụfọdụ atụmatụ ndị ọzọ dị ka mmezi, ihe dị ala, na-enye ọkpọkọ nke A335 p91 p91 p91 p91 p91 p91 pyel pipes maka ọtụtụ ngwa ọrụ na ụlọ ọrụ dị iche iche.

ASTM A315 tubing nwere obere ihe nke alloys ndị ọzọ dị ka alumium, NIKEL, nitrogen, Daninium, na Zirconium. Ọkpọkọ ndị a dabere na A335 ọkọlọtọ, ma mgbe agbagharala ma ọ bụ gwuo ya, ọkpọkọ ahụ nwekwara ike izute ọkọlọtọ A369. Pipes ndị a nwere ike iji ike opera 415 na obere Tensa Exer nke 585 MPA.

Ọdịdị chromium dị elu na-enye oghere steel nke ndị a na-agbagide dị mma na-eguzogide oke mmiri nke mmiri, nke na-emekwa ka ike dị elu na nguzogide na-agbacha elu okpomọkụ.