Baetsi ba Litšoantšo tsa tšepe tsa tšepe tsa tšepe 316l 1.4401 s31601 s31603 steel phala ea tšepe

Bakeng sa ho fetisa pompo, ho bohlokoa ho tlosa hose e otlolohileng hodima pepeng. Ha u sebelisa lipeipi tse fapaneng, lipeipi tse fapaneng li lokela ho sebelisoa. Ha pampiri e sebelisoa, ethe e lokela ho sebelisoa ho fetola boholo ba pompoine. Ha phala e meraro ea mekhoa e meraro e sebelisitsoeng ha lenonyeletso e sebelisoa le pompo ea sebaka se seng le se seng le se seng le se seng sa ho fulatsa. , Ka khokahano ea liletsa tse fapaneng, ho boetse ho na le lihokelo le likoto tsa moqhaka.

Ho tloaelana ke mokhoa oa kalafo oa mocheso o sebelisoang ho etsa hore ho be le mokhoa o tukang kapa oa ho etsa lintho tse thatafatsang kapa tsa ho thatafala. Ho tloaelehileng ho kenyelletsa ho futhumatsa boitsebiso bo phahameng mocheso o phahameng ebe o bo pepesetsa ho ea kamoreng ea mocheso ka mor'a ho futhumatsa, ho e lumella ho futhumatsa mocheso oa kamore. Ho futhumatsa le ho fofa butle ho koahela likokoana-hloko tsa tšepe, li fokotsa boima ba sona le ho eketsa dunality ea eona.

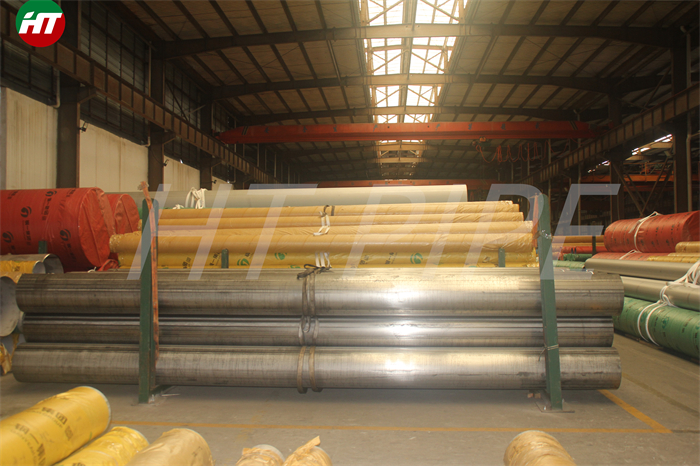

Tšepe e se nang thuso le eona e sa nke lehlakore ebile e se e le mateane, 'me nako ea bophelo ea eona e telele ebile e tiisa hore e kopana le litlhoko tse tsitsitseng. Ntle le moo, ha e bue ka sebopeho sa eona ha e buisana le lintho tse kang metsi.

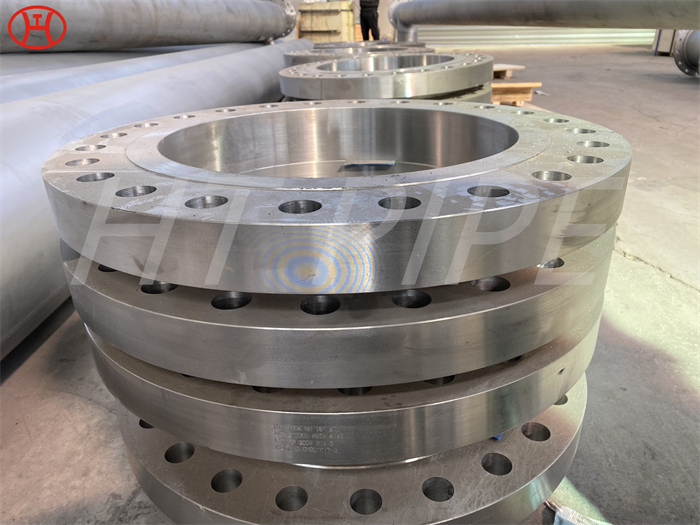

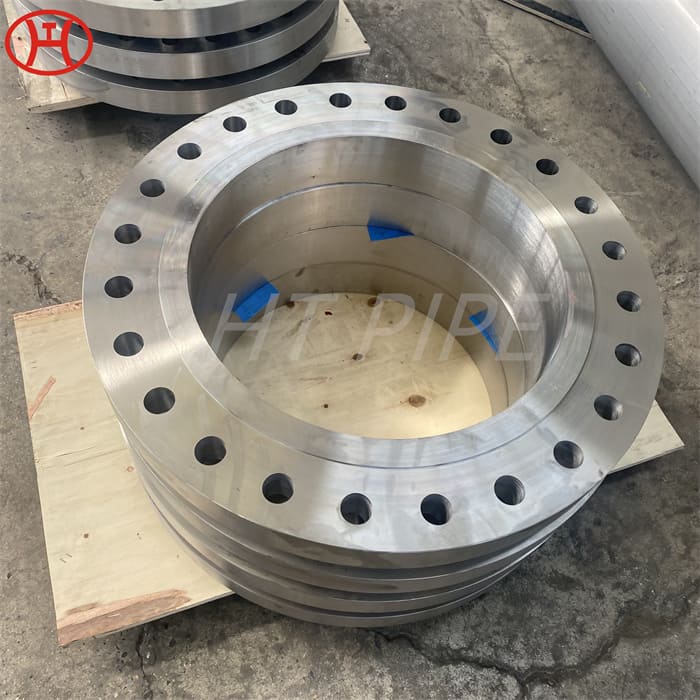

Litlama ke li-module, tse sebelisoang ho kopanya merung ea lipaki le boholo bo fapaneng. Ho sebelisana le maemo hangata ho entsoe ka lihlopha tse fapaneng, tse thusang ho sebelisa le ho khetholla likarolo tse fapaneng tsa lihlahisoa. Iso le ANSI ke litekanyetso tsa bohlokoa, tse laolang liindasteri.

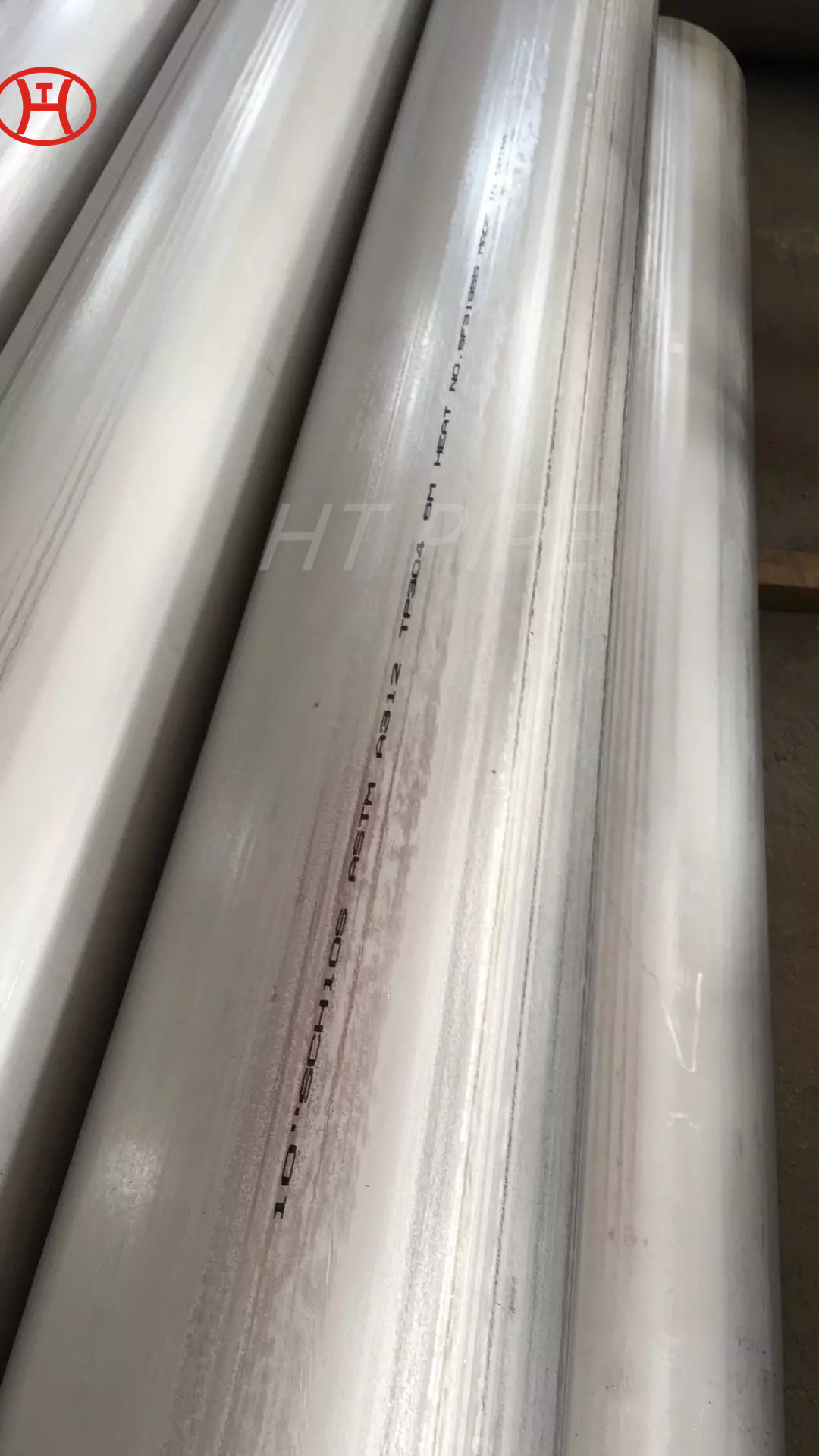

304 Lisebelisoa tsa pampiri li entsoe ka tšepe ea 304 e nang le linoko, e tloaelehileng le e tsebahalang likopo tse ngata tsa indasteri e hlokang ho hanyetsa mohatleng le oxidation. Litšila tsena tsa petso tsa S30400 li lula li sebelisa mochini le lits'ebetso tse ikhethang, tse netefatsang hore li nepahetse ebile li tšepahala.

Libiti tsa 321 li koahela molao oa ho ts'oaroa ka mokhoa o sa sebetseng oa tšepe bakeng sa khatello ea lisebelisoa tsa poping. Lintho tsa bohlokoa tsa li-pipi li tla kenyelletsa lijo, mekoallo, lipolanete kapa lipompo tse sa sebetseng. Forging or forming operations shall be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining, or a combination of two or more of these operations. Lisebelisoa tsohle li lokela ho ba mocheso.