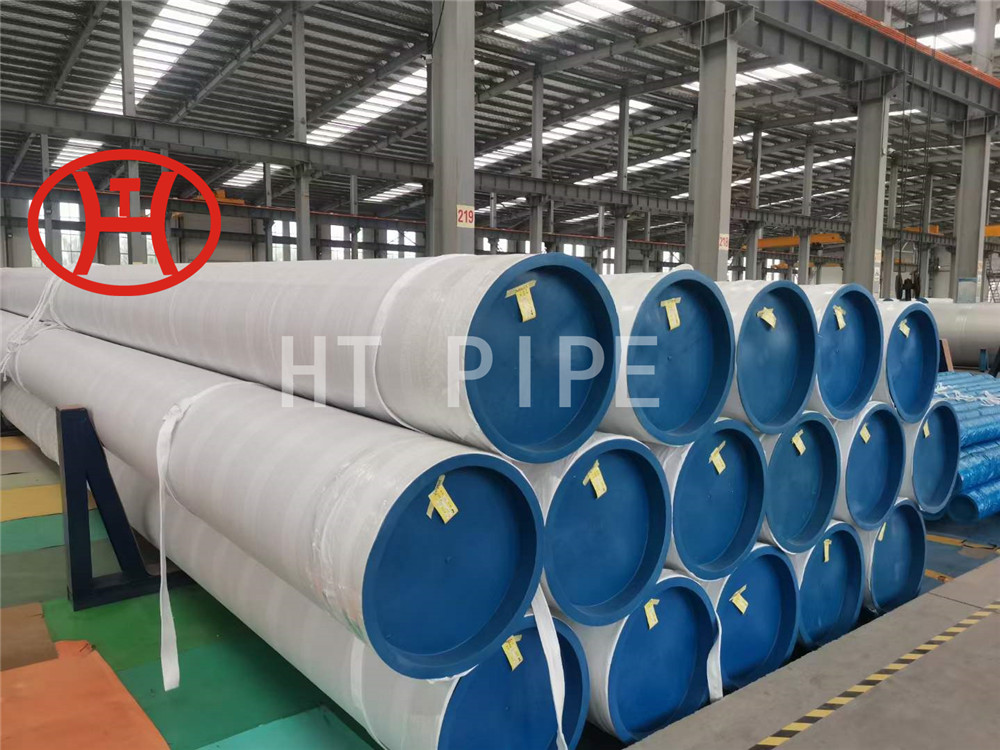

Piloy irin Pipe ASTM A335 P23 P22 P22 ni iṣura

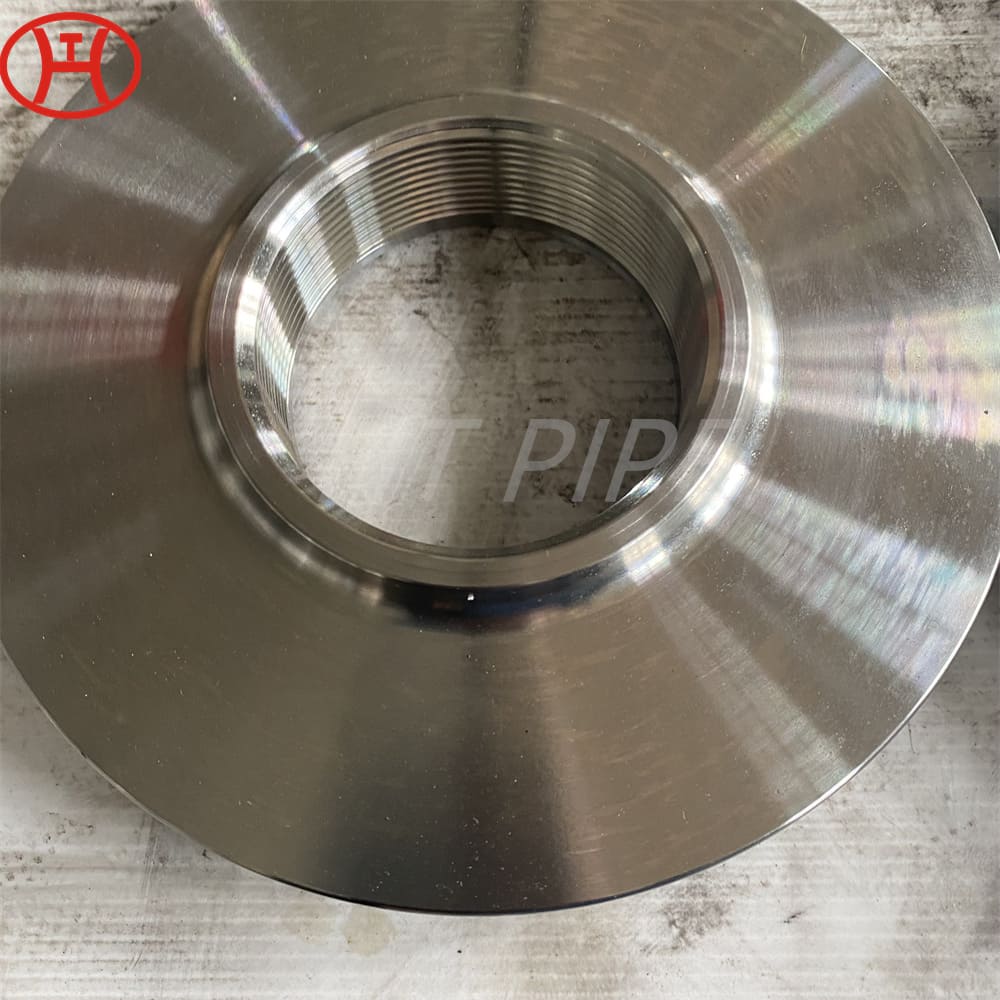

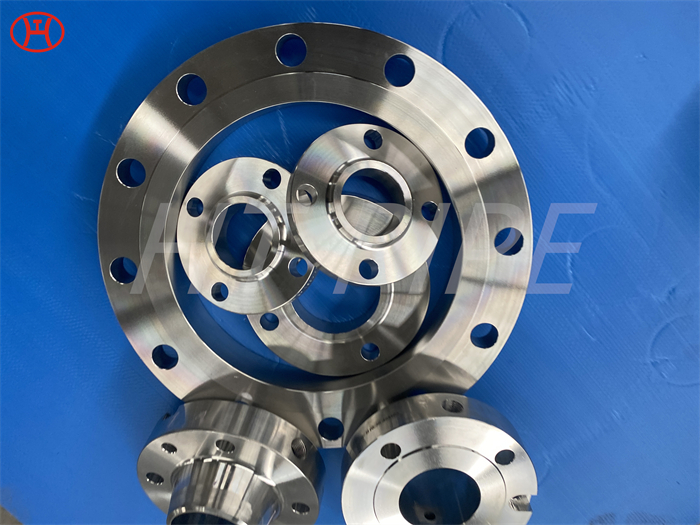

Although acceptable fouling levels are considered beneficial to the alloy, in moderate cases, fouling deposits on Astm A182 F9 flange surfaces can act as a barrier to excessive corrosion. Nigbati awọn ẹru ti wa ni iṣelọpọ lilo afiwera A182, wọn ṣiṣẹ daradara ni awọn iwọn otutu giga, botilẹjẹpe ninu awọn ohun elo pẹlu titẹ giga.

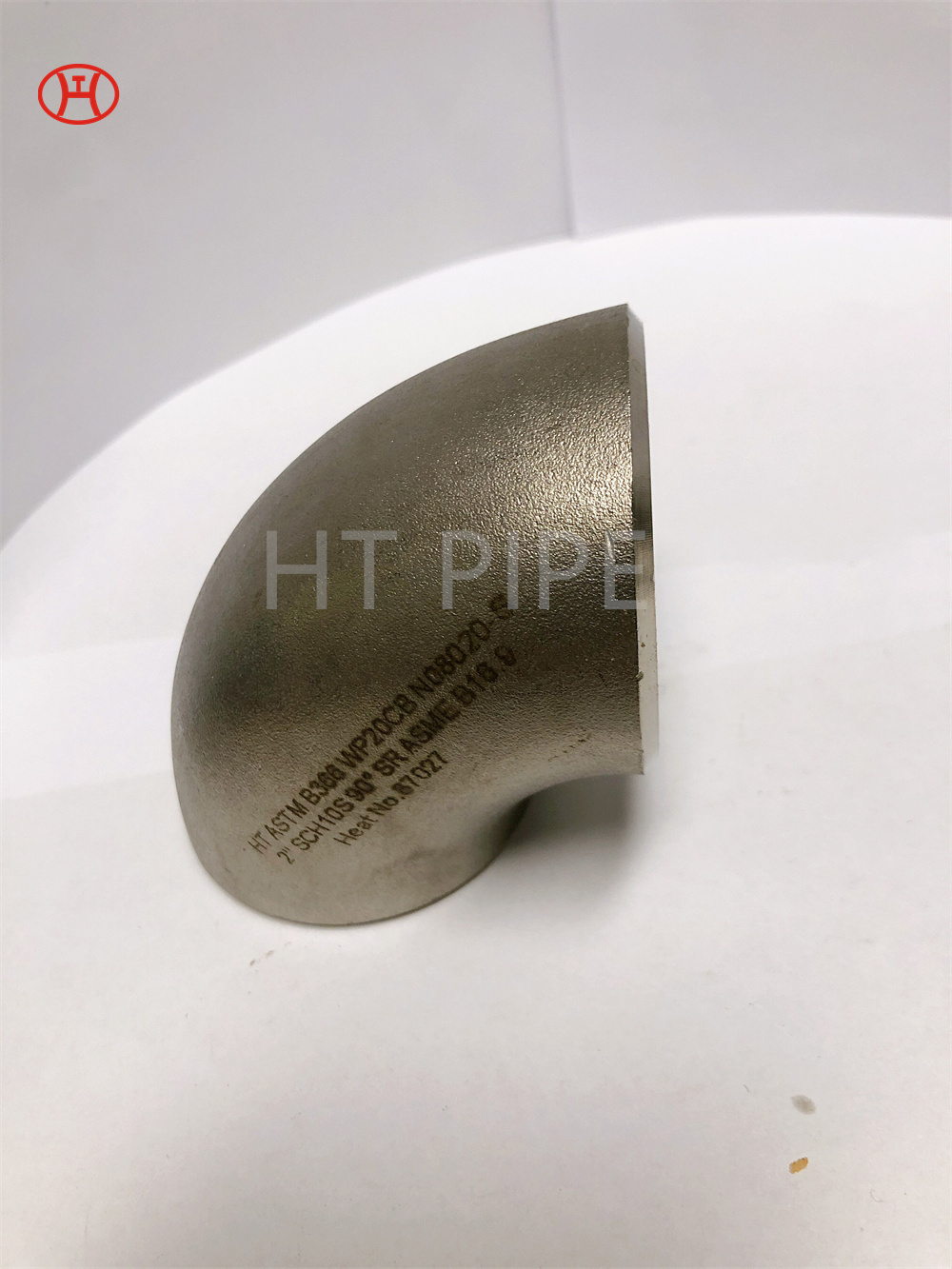

Ni sisọ, gbogbo irin jẹ ohun alloy, ṣugbọn kii ṣe gbogbo awọn irin a npe ni "awọn irin alagbara". Awọn irin ti o rọrun julọ jẹ irin (Fee) pẹlu erogba (c) si 1.1% si 1%, da lori 1%, da lori oriṣi) ati ohunkohun miiran (aifiyesi kakiri wa nipasẹ awọn aarun kekere); Wọnyi ni a pe ni awọn irinro erogba. Sibẹsibẹ, ọrọ "Alloy irin" jẹ ọrọ boṣewa tọka si awọn irin-ajo pẹlu awọn eroja gbogbo awọn aja miiran ti a fi mọọmọ ni afikun si erogba. Awọn Allorates ti o wọpọ pẹlu manganese (ọkan ti o wọpọ julọ), nickel, crumium, molybandlum, Velonimu, Valion, ati Boron. Awọn Allorates ti o wọpọ pẹlu Aluminium, Chobiti, Ejò, nibium, Titanium, Ale-pẹ, ati zirconium.

Awọn ọja ti a ṣe lati irin Mopoy ti o dara julọ ju ti a ṣe lati irin irin lọ. Botilẹjẹpe wọn ko gbowolori ju awọn onipò irin alagbara ju, wọn ko le sooro si ipanilara ju irin alagbara, ati diẹ sii sooro ju pọnti irin irin igi.