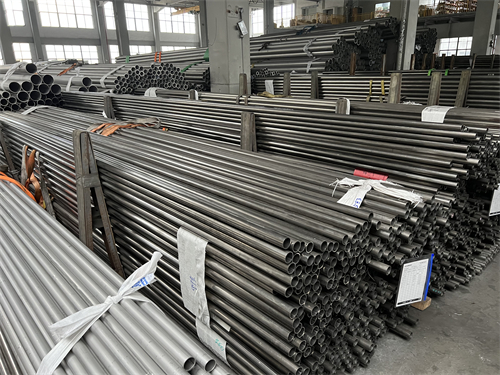

ASTM A312 TP316 Seamless Industrial Steel Pipe UNS S31600 SMLS Steel Pipe

ASTM A312 TP316 is a standard specification for seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipes used in high-temperature and general corrosive service applications. The 316 Seamless Industrial Steel Pipe is made from a combination of chromium, nickel, and molybdenum, which gives SS 316 Seamless Tube excellent resistance to corrosion and rust.

ASTM A312 TP316 Seamless Industrial Steel Pipe, SS 316 Seamless Tube, ASTM A312 TP316 Pipe Supplier, Stainless Steel 316 Tube, 316 Stainless Steel Seamless Tubing, SA 312 TP 316 Pipe, WNR. 1.4401 Pipe, UNS S31600 SMLS Steel Pipe.

ASTM A312 TP316 is a standard specification for seamless, straight-seam welded, and heavily cold worked welded austenitic stainless steel pipes used in high-temperature and general corrosive service applications. The ASTM A312 TP316 Seamless Industrial Steel Pipe is made from a combination of chromium, nickel, and molybdenum, which gives UNS S31600 SMLS Steel Pipeexcellent resistance to corrosion and rust.

The ASTM A312 TP316 Pipeis one of the most popular variations of the A312 TP316 among various industries. SS 316 Seamless Tubeis particularly useful in applications that require high strength and corrosion resistance, such as chemical processing, marine engineering, petrochemical refining, oil and gas exploration, and power generation.

One of the key benefits of the 316 Stainless Steel Seamless Tubingis its ability to withstand high temperatures. 316 Stainless Steel Seamless Tubing operates continuously at temperatures up to 1,650°F (870°C) and intermittently at temperatures up to 1,800°F (982°C), making SA 312 TP 316 Pipean ideal solution for hot process environments. Additionally, the WNR. 1.4401 Pipe’s high corrosion resistance allows UNS S31600 Pipe to perform well in harsh chemical environments, such as those that involve exposure to sulfuric acid, hydrochloric acid, and caustic soda.

Another selling point of the A312 TP316 seamless industrial steel pipe is its durability. The 1.4401 Pipe‘s high tensile strength and toughness enable it to withstand heavy loads, high pressures, and extreme temperatures without cracking or failing. This durability ensures that the 316 Seamless Industrial Steel Pipe can last for many years, even in demanding industrial applications.

Finally, the A312 TP316 seamless industrial steel pipe is available in a wide range of sizes and wall thicknesses to meet the needs of different industries. UNS S31600 Pipecan be custom-fabricated to specific requirements, such as length, diameter, and end connections, making 1.4401 SS Pipe highly versatile and adaptable to a variety of applications.

The ASTM A312 TP316 seamless industrial steel pipe is a reliable and versatile solution for various industries. Its excellent resistance to high temperatures, corrosion, and rust, along with its durability and customization options, make 316 Stainless Steel Seamless Tubinga top choice for demanding applications. Whether it’s used in chemical processing, marine engineering, petrochemical refining, oil and gas exploration, or power generation, the A312 TP316 seamless industrial steel pipe delivers exceptional performance and value.

Chemical Element of SS DIN 1.4401 SMLS Pipe

| Grade | 316 | |

| min | max | |

| C | – | 0.08 |

| Mn | – | 2.0 |

| Si | – | 0.75 |

| P | – | 0.045 |

| S | – | 0.03 |

| Cr | 16.0 | 18.0 |

| Mo | 2.0 | 3.0 |

| Ni | 10.0 | 14.0 |

| N | – | 0.10 |

Mechanical Properties of SS UNS S31600 Round Pipe

| Grade | 316 | |

| Tensile Strength (MPa) min | 515 | |

| Yield Strength 0.2% Proof (MPa) min | 205 | |

| Elongation (% in 50mm) min | 40 | |

| Hardness | Rockwell B (HR B) max | 95 |

| Rockwell B (HR B) max | 217 | |