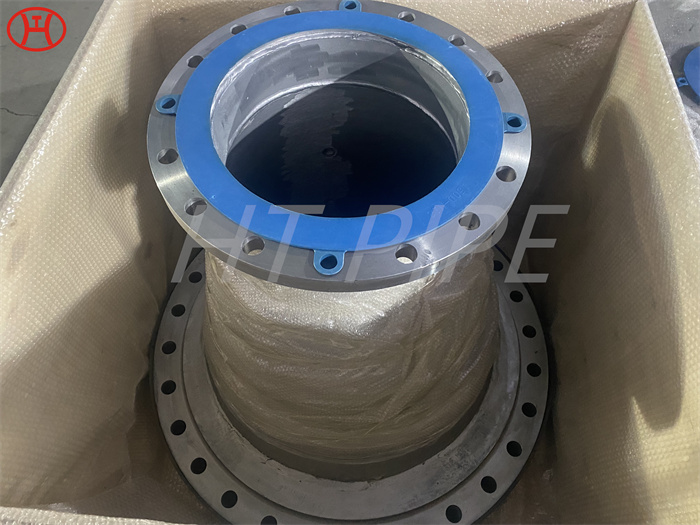

Izilinganiso ze-Flange eziyi-150 ze-Flange ezingenasici ezingenasici

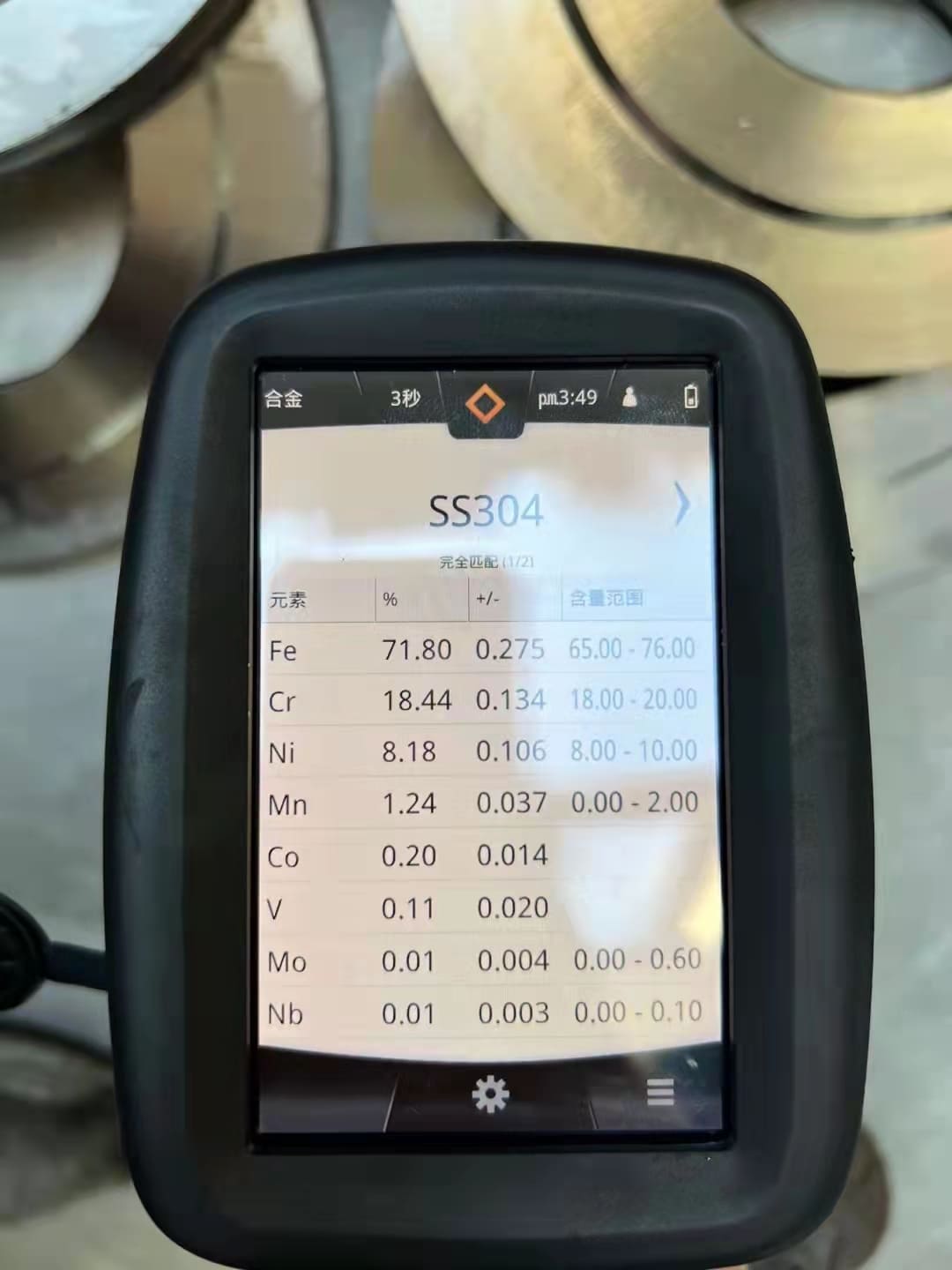

Lapho kudingeka i-welding, insimbi inempahla yokuqhekeka njengoba ipholisa. Amazinga okushisa aphezulu wenqubo yokufaka i-welding abangela lokho okwaziwa ngokuthi "ukufezekiswa okushisayo" njengopholile wensimbi. Lokhu kwenza izakhiwo zakhiwe ngensimbi ephezulu yokuqukethwe kwekhabhoni zithambekele ekulimaleni ngenxa yokwakhiwa kwemifantu ezindaweni lapho insimbi ifakwa khona insimbi. I-Alloy yensimbi engagqwali isetshenziswa ezinhlobonhlobo zezicelo njengoba ilungele kahle ukugwema ukugqwala kwe-weld. Futhi ingamelana namazinga okushisa aphezulu futhi inendawo ephezulu yokuncibilika cishe ngama-degrees Celdius acishe abe ngu-2,500 ama-degrees acishe abe ngu-1,370. Ngaphezu kwekhabhoni, le alloy iqukethe u-2% manganese futhi aze afike ku-0.75% salicon.

I-316l ibanga eliphansi lekhabhoni elingama-316. Leli banga alithinteki ngokuzwakala (imingcele ye-carbide ye-carbide). Imvamisa isetshenziselwa izingxenye ezisindayo ze-welded (cishe ngaphezulu kwe-6mm). Awukho umehluko wentengo ebonakalayo phakathi kwensimbi engama-316 ne-316l. Uhlobo lwe-316 i-auntenitutic yensimbi engenacala ngokungezwa kwe-molybdenum ukwenza ngcono ukumelana nokugqwala kwe-alloy. Kucishe kube njengokuthandwa kwezentengiso njengensimbi engama-304 engagqwali.