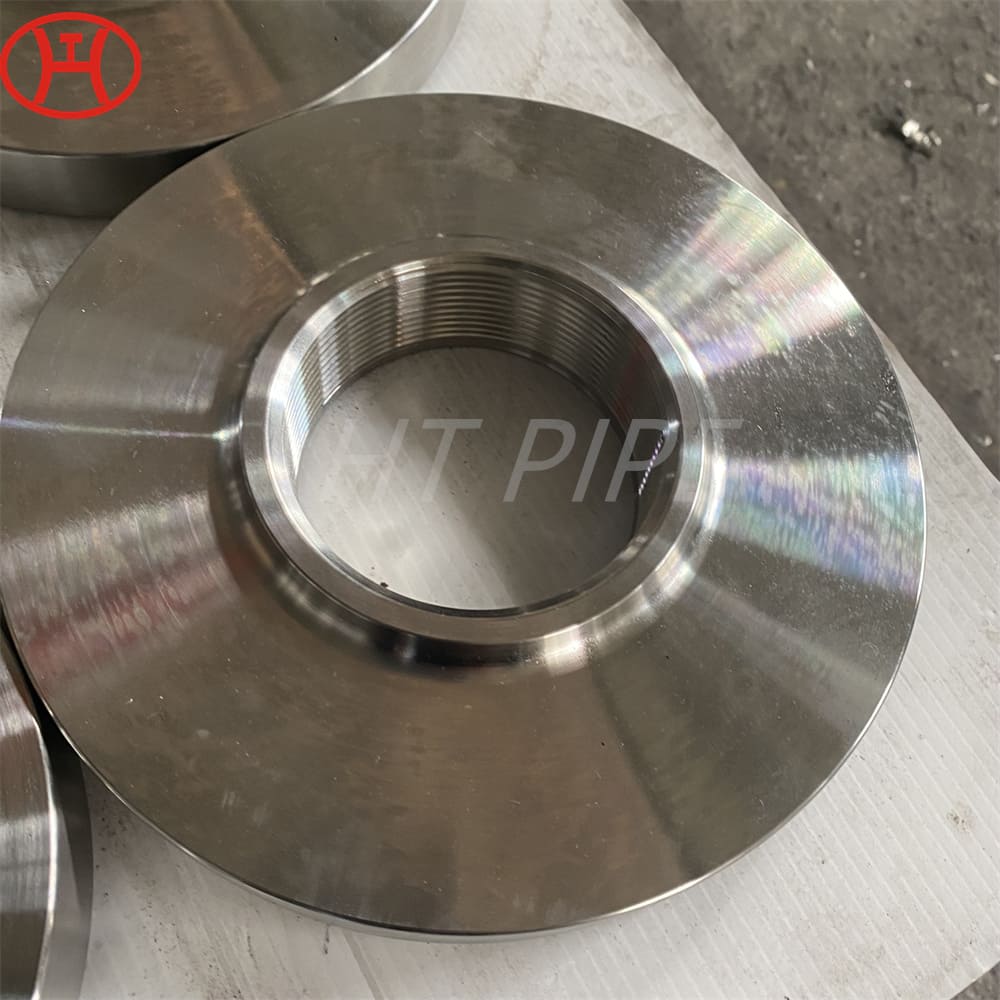

USemi uqede i-flange a182 f9 wn flange asebenzisa amapayipi nezinhlaka

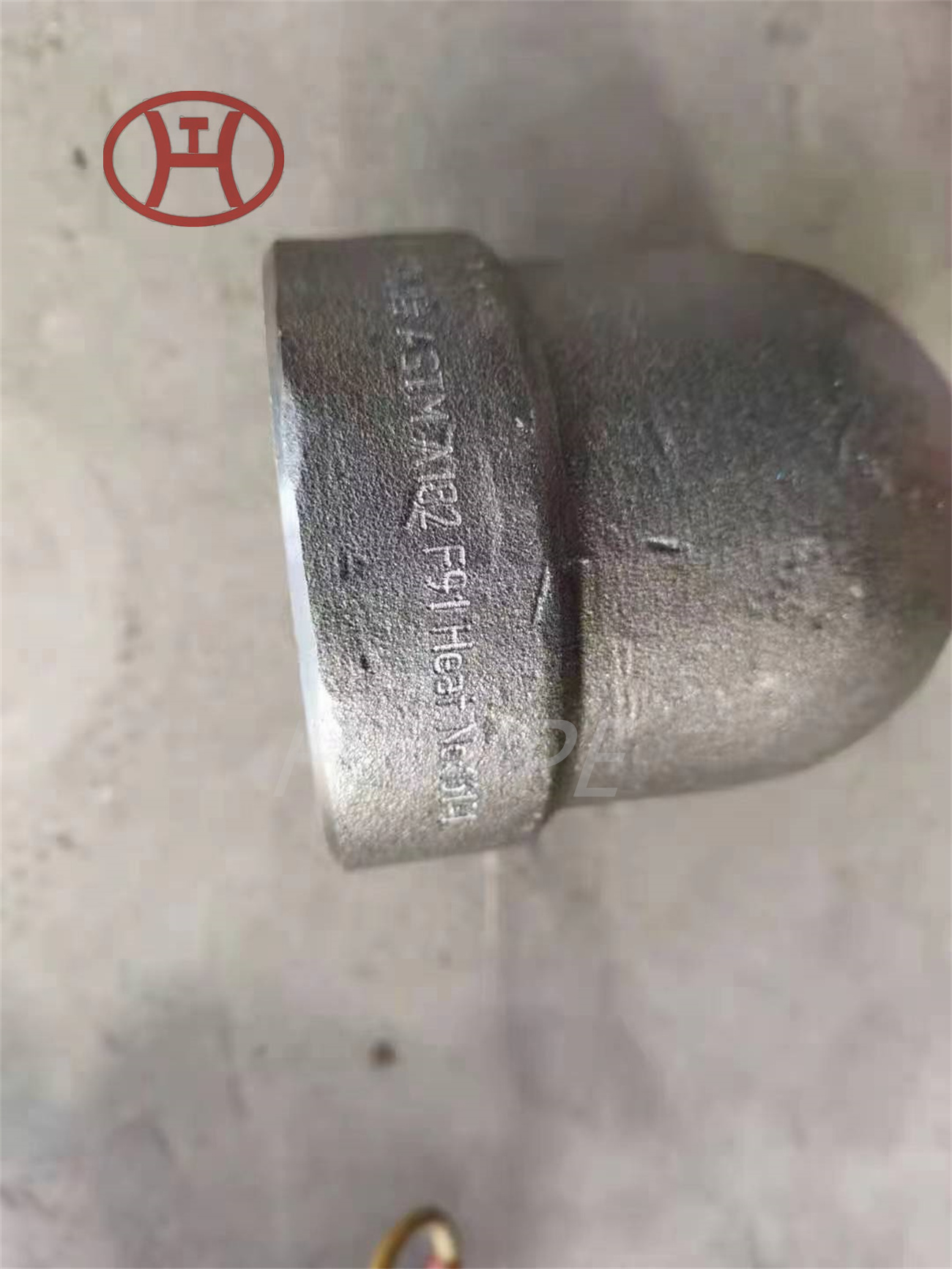

INilo Alloy 36, w.nr 1.3912, i-Invar 36® iyi-nickel-iron, i-alloy elawulwa okuphansi equkethe ama-nickel angama-36% futhi anezinga lokunwetshwa kwensimbi ecishe ibe yishumi lensimbi ye-carbon.

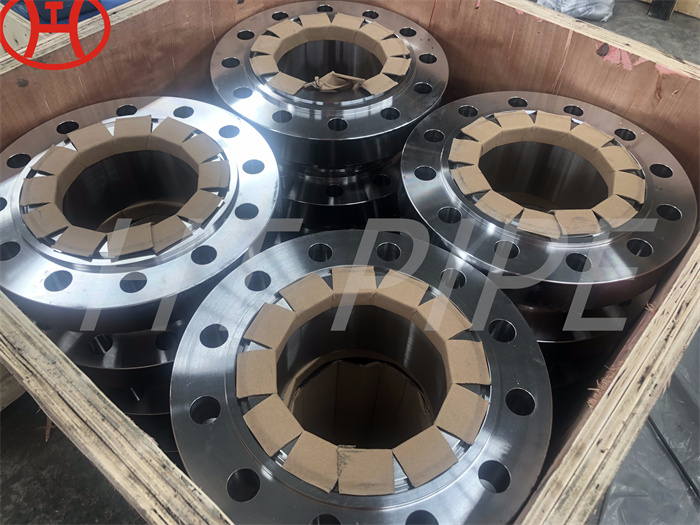

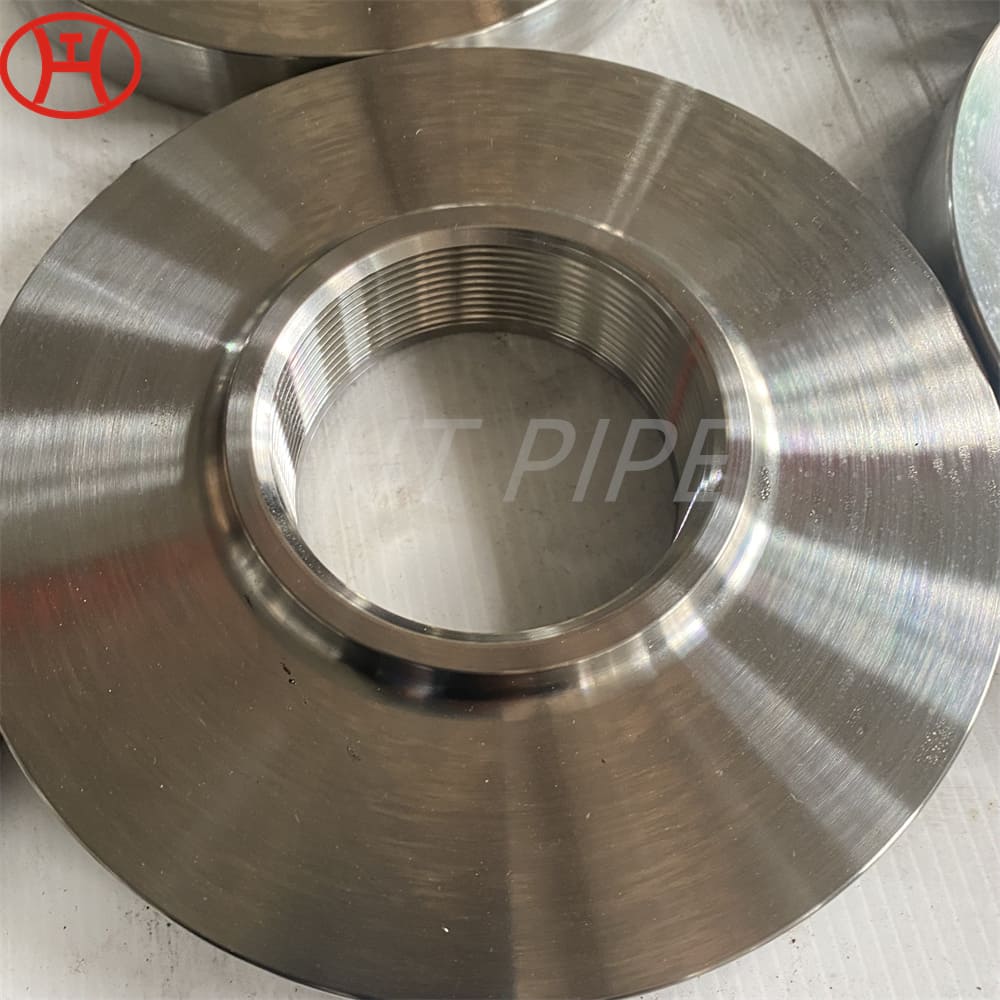

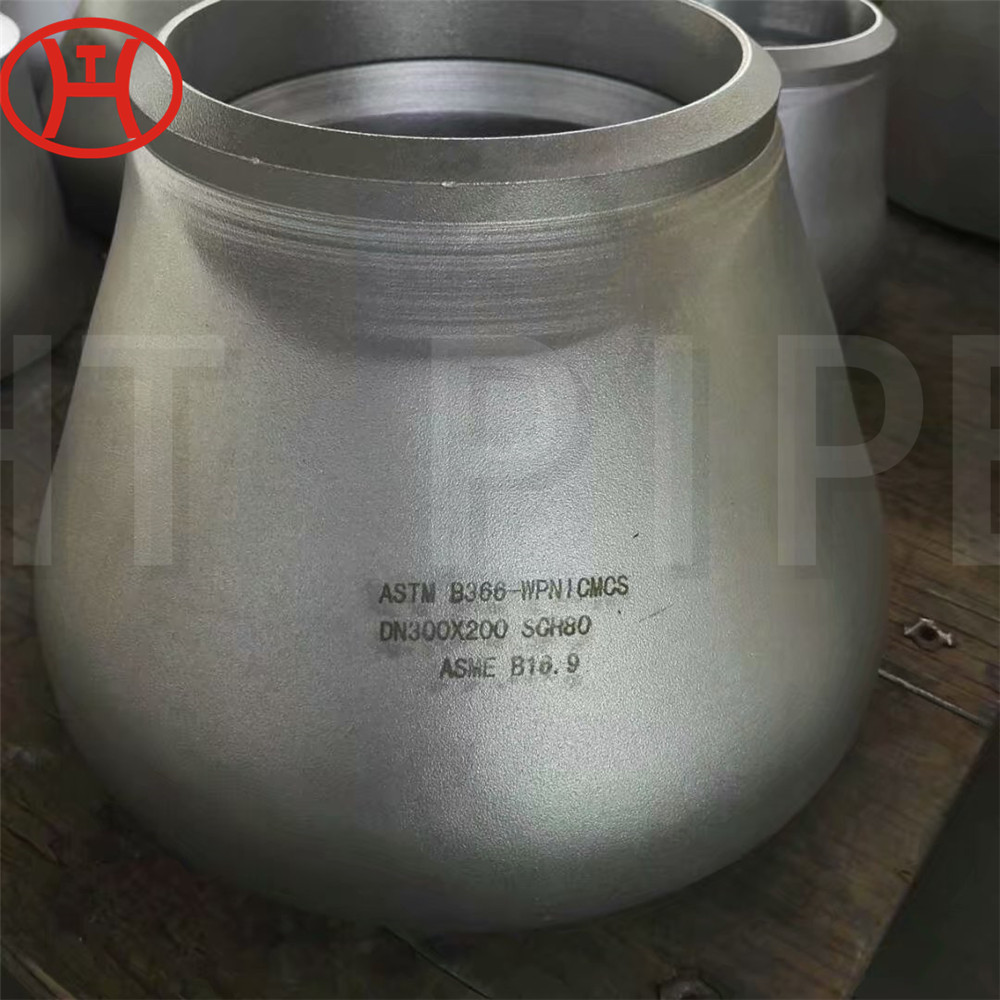

Izinto zayo ezivamile zingu-12cr1mov, i-15CRMO, P91, P22, 10CRMO910 nokunye. Ilungele ukuxhumeka kwepayipi kwe-carbonnsimbi ye-carbon nengcindezelo engaphezu kwe-2.5MPA. Ingaphezulu lokubopha uphawu le-welding filange lenziwe ngezinhlobo ezintathu: uhlobo olubushelelezi, uhlobo lwe-concave-convex kanye nohlobo lwe-yotie-and-grove. Ukusetshenziswa kwe-application ebushelelezi ye-welding flange. Kuyinto ebaluleke kakhulu ethinta ukucaciswa kwe-PCR. Ngokufanelekile, izinga lokushisa le-annelling liphansi ngokwanele ukuqinisekisa umnsalo, namakholomu ukunxusa kahle, kuyilapho futhi uphakeme ngokwanele ukunciphisa ukubopha okungacaciswanga. Amazinga okushisa anengqondo aqala kusuka ku-55¡Ãc ku-70¡Ãc.