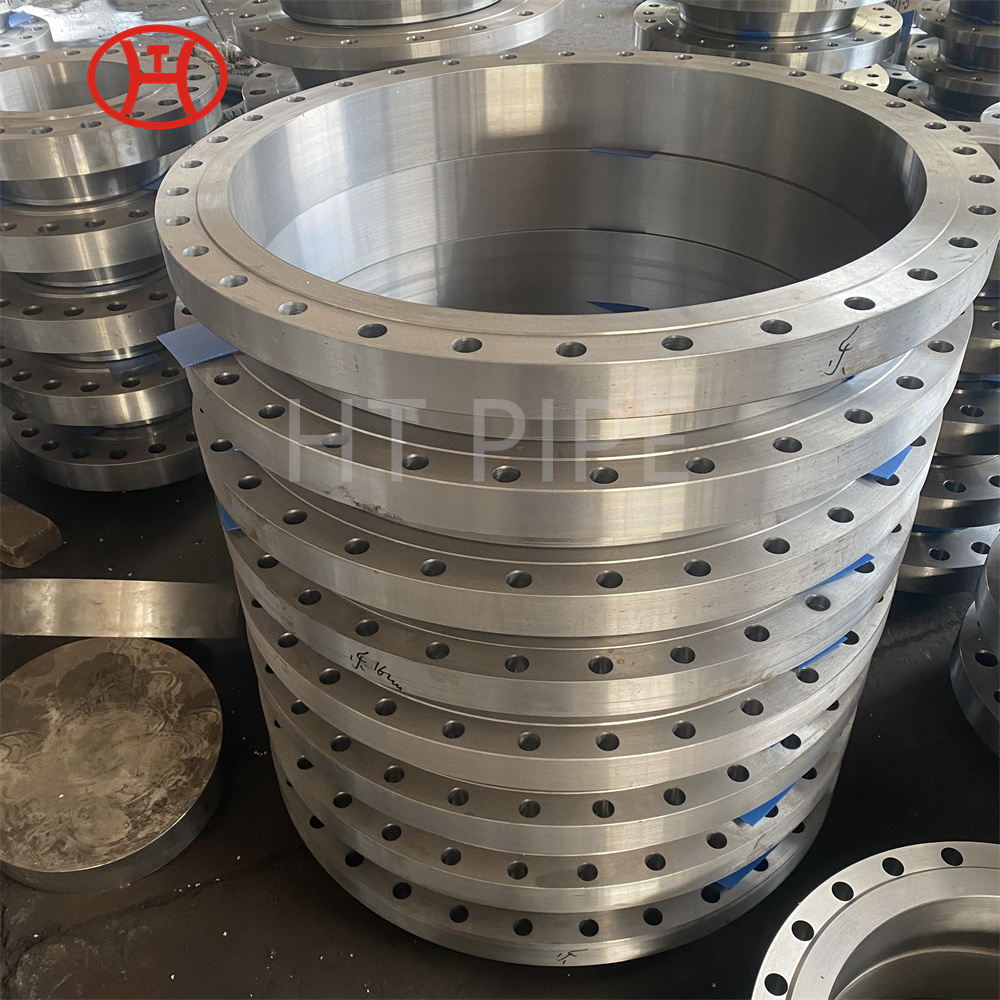

I-Chrin 625 Abahlinzeki be-Flange ban n06625 blrf flange

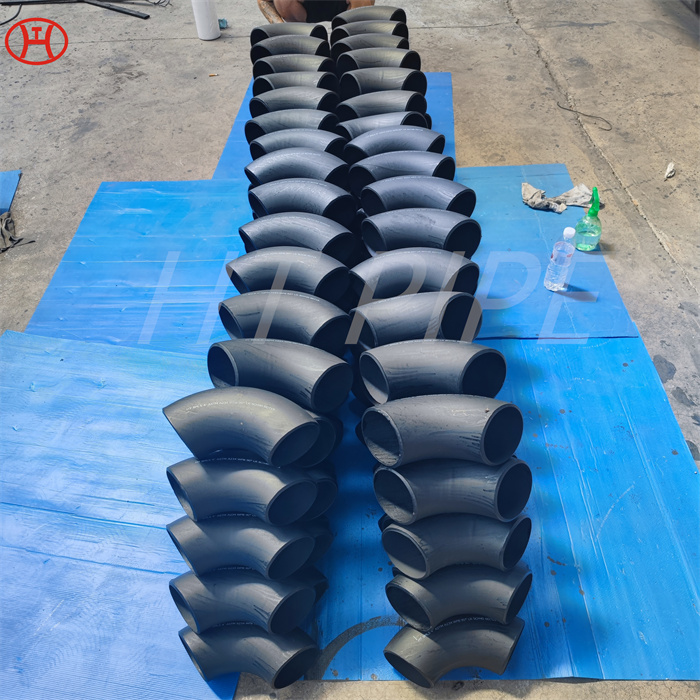

Lokhu okuqukethwe kuhlala isikhathi eside, kubiza okuphansi, futhi kunzima ukuphula. Uma kwenzeka kusetshenziswa ohlelweni lwamapayipi ensimbi olungenasici luzoguqulwa ngendandatho ehlanganyelwe ye-LAP.

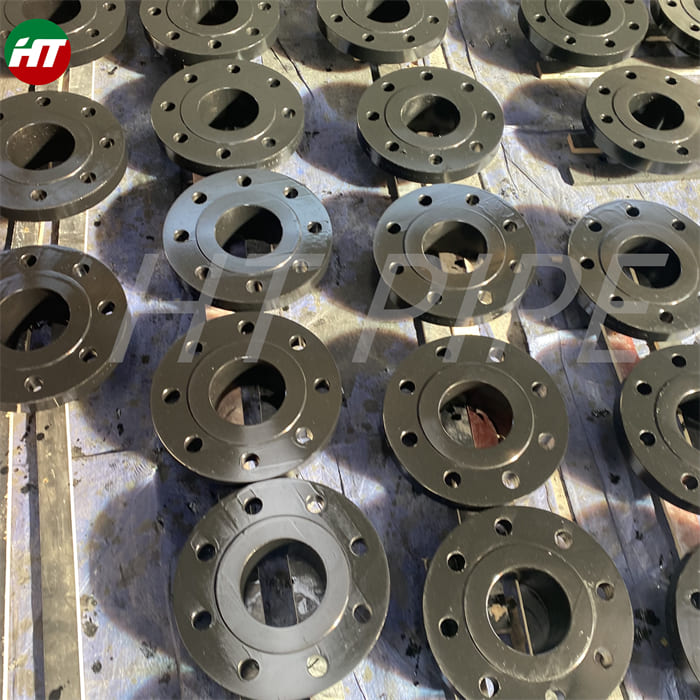

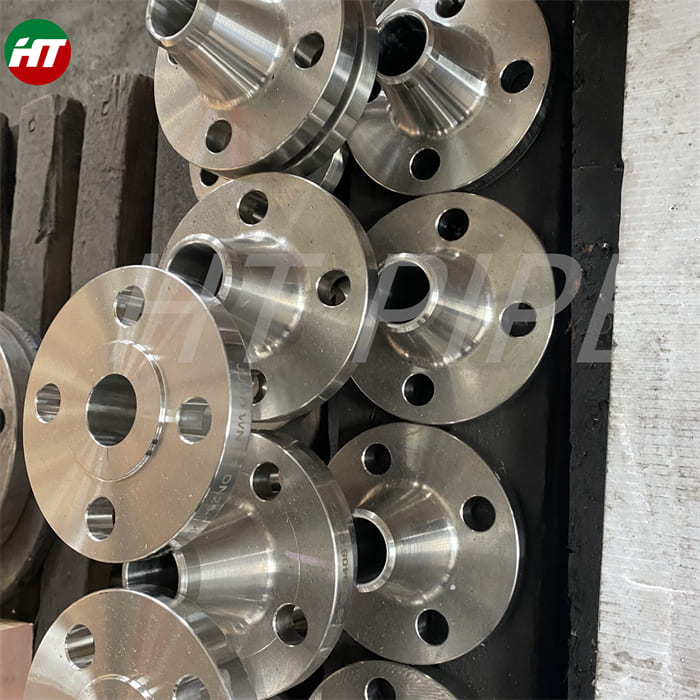

Yakhelwe ngqo ukusetshenziswa kwezinga lokushisa okuphansi, leli banga lensimbi yekhabhoni lihlanganyela ukufana okusondelene nebanga le-ASTM A105N (SA105n). Leli banga lidinga ukuhlolwa kokuqina kwe-notch, futhi kusebenza kwizimboni eziningi. Lelibanga lensimbi ye-carbon libuye lisetshenziswe ekufakweni kwensimbi ephansi yekhabhoni. Izindinganiso ezibekwe i-ASTM A694 zilukhuni ukwedlula lokhu okungenhla. Izidingo zayo zokudluliselwa kwamanzi okuphezulu kwengcindezi yamafutha kawoyela negesi kuyahlanya. Ngenxa yezimo eziqinile ngebanga lensimbi, abakhiqizi kufanele bathuthukise insimbi eqine kakhulu kuwona womabili amazinga okushisa aphansi kanye namazinga okushisa aphezulu. Kunegceke eliphansi lesivuno eliza nebanga lonke le-A694. The most common material grade in use today is A105 forged carbon steel, with sizes ranging from 1\ 2¡° ¨C 24¡± in ASME B16.5, 26¡± ¨C 60¡± in ASME B16.47, and 26¡± ¨C 96¡± in B16.1 (for temperatures ranging from ambient up to 1,000 Fahrenheit and pressure between 20 ¨c 6,170 PSI). Ukushisa okubanzi nokucindezela kwenza i-carbon steel Flanges isixazululo esikhangayo sohlelo lokusebenza lwezimboni eziningana, futhi selufakazele ukuthi lungenye yezinketho zamanani ezibizayo.