I-ASME B16.5 Insimbi Engagqwali Inkolo Engagqwali

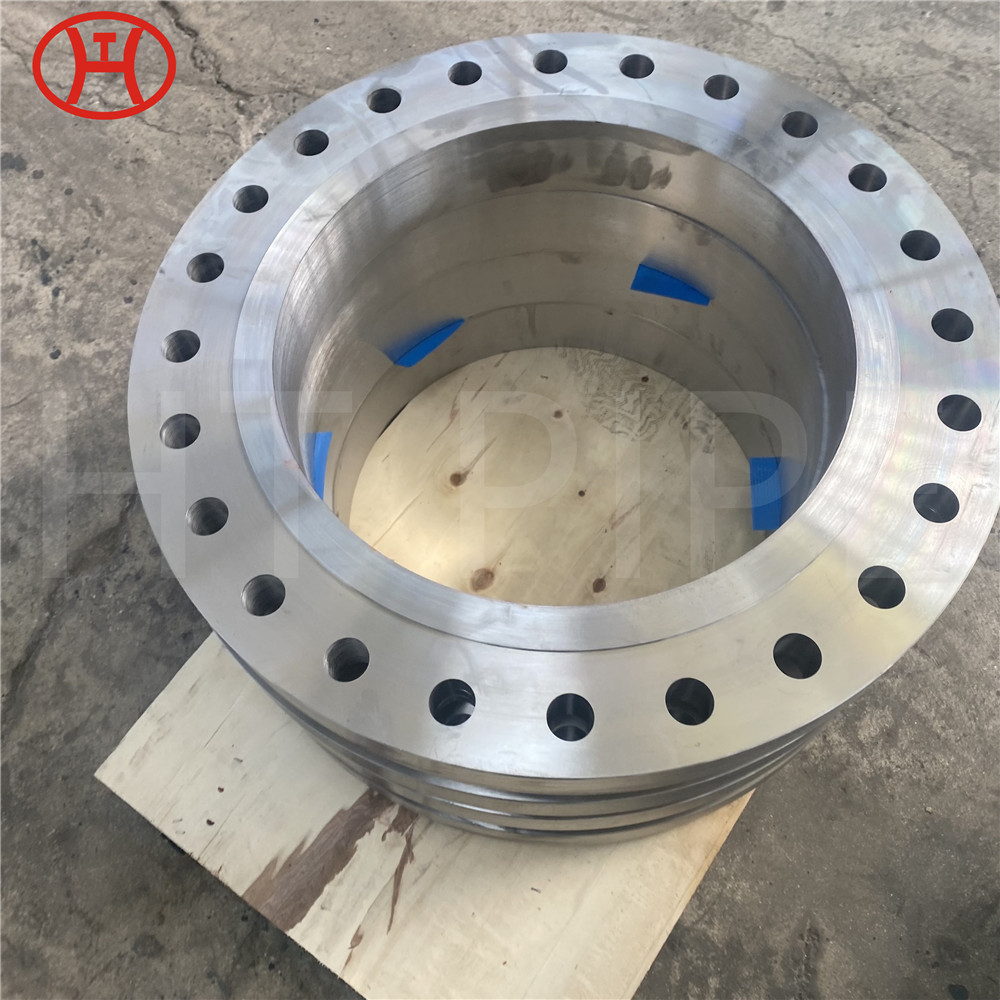

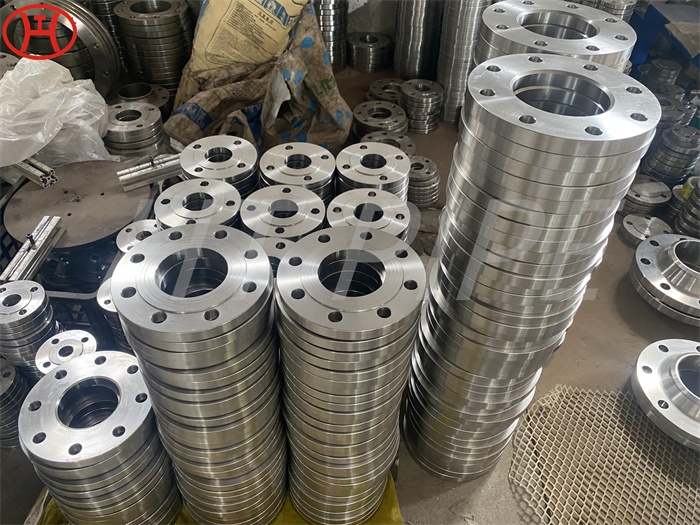

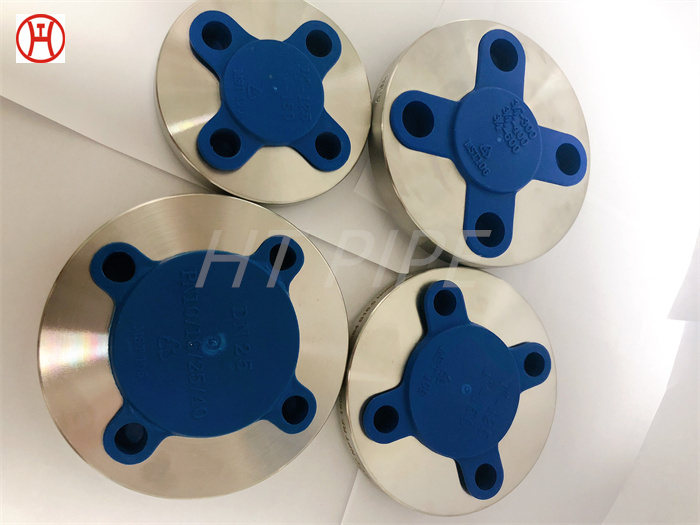

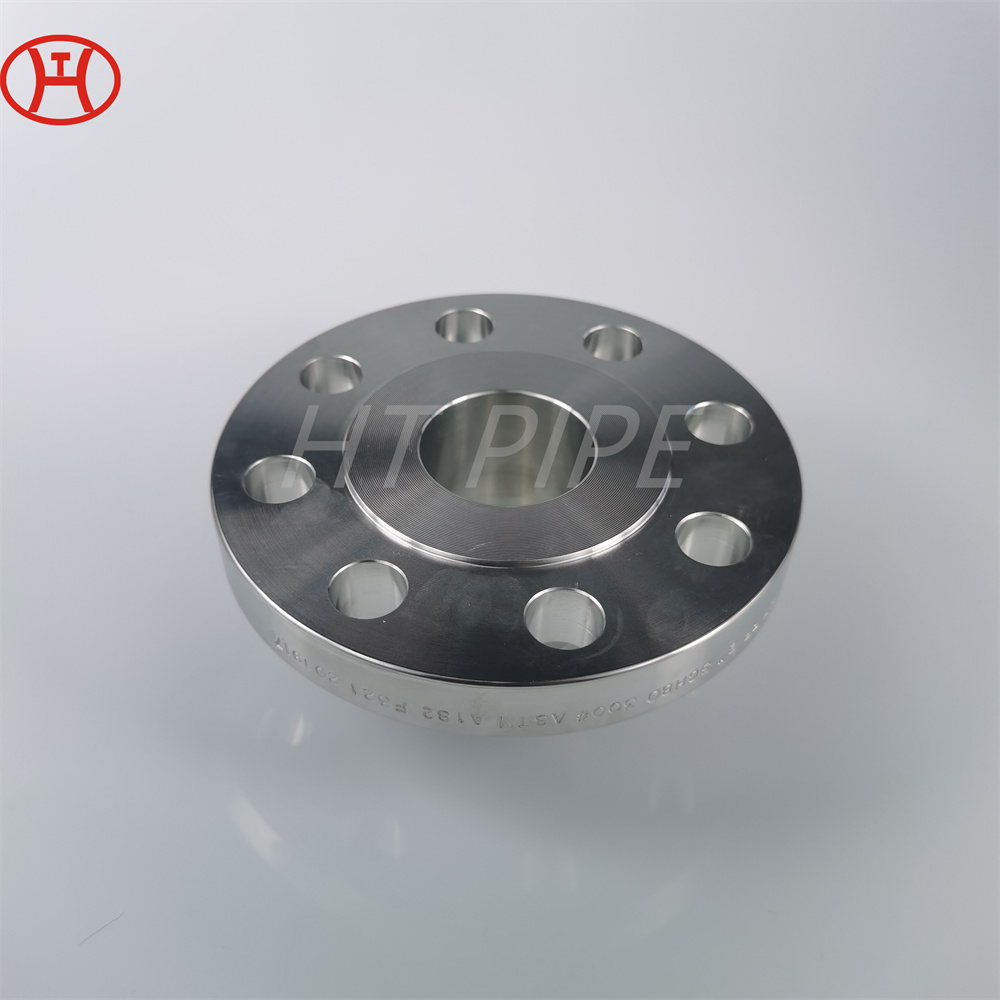

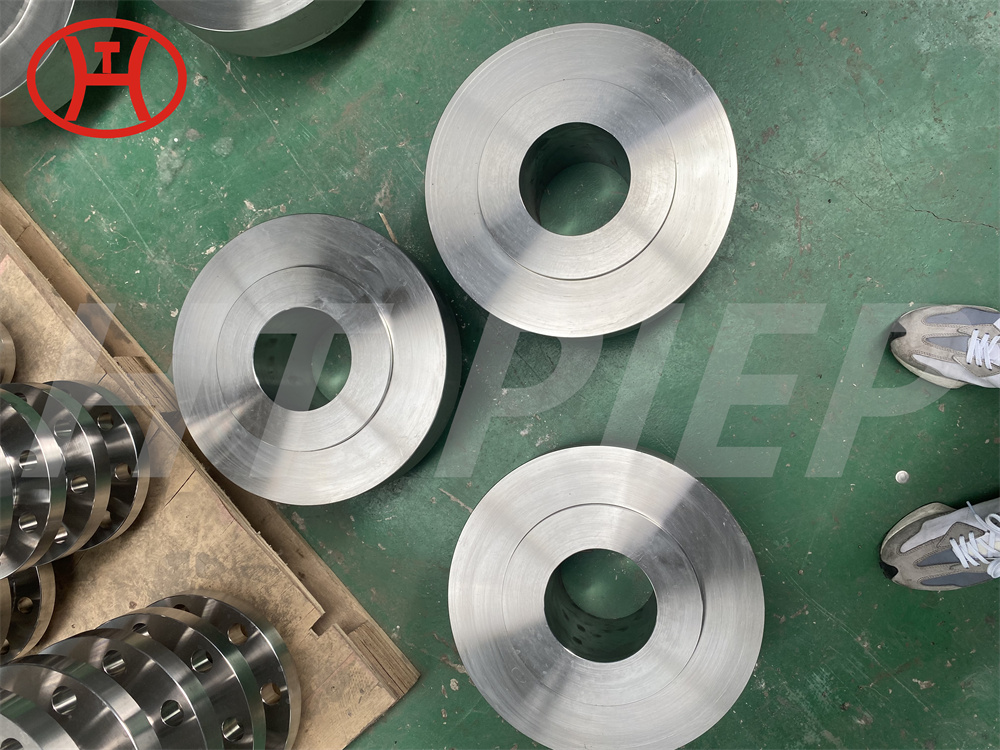

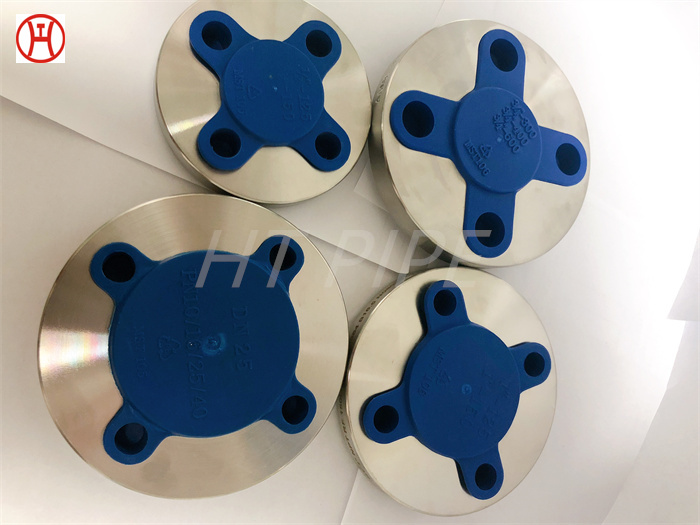

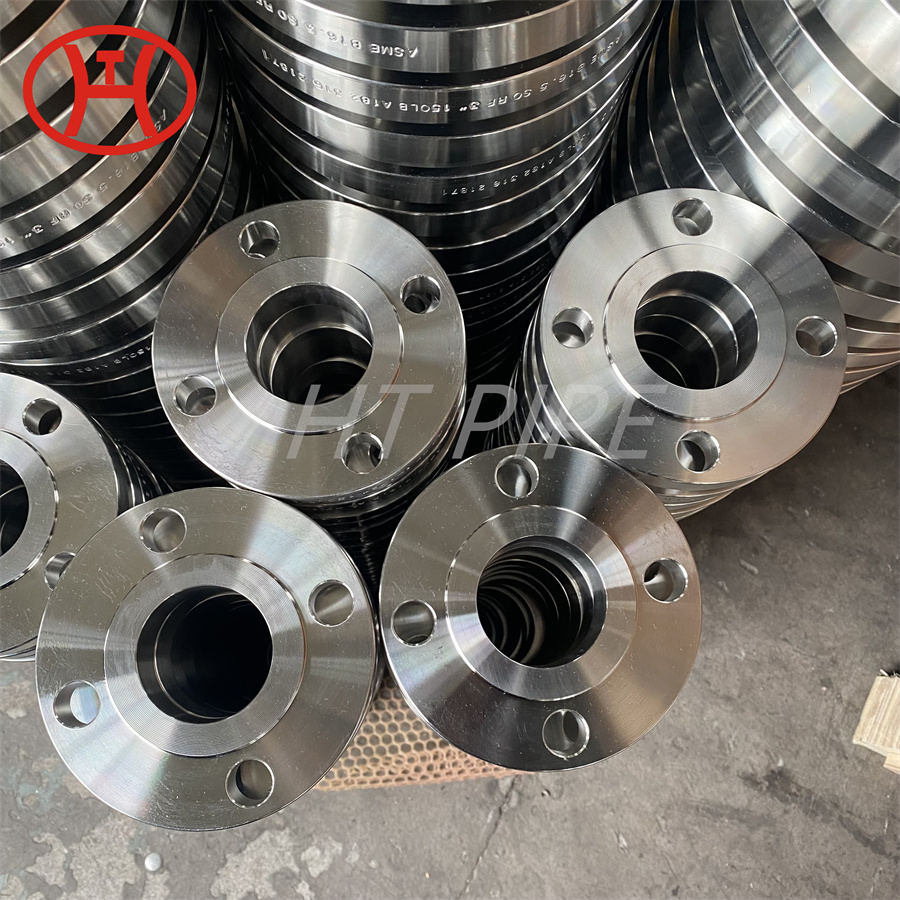

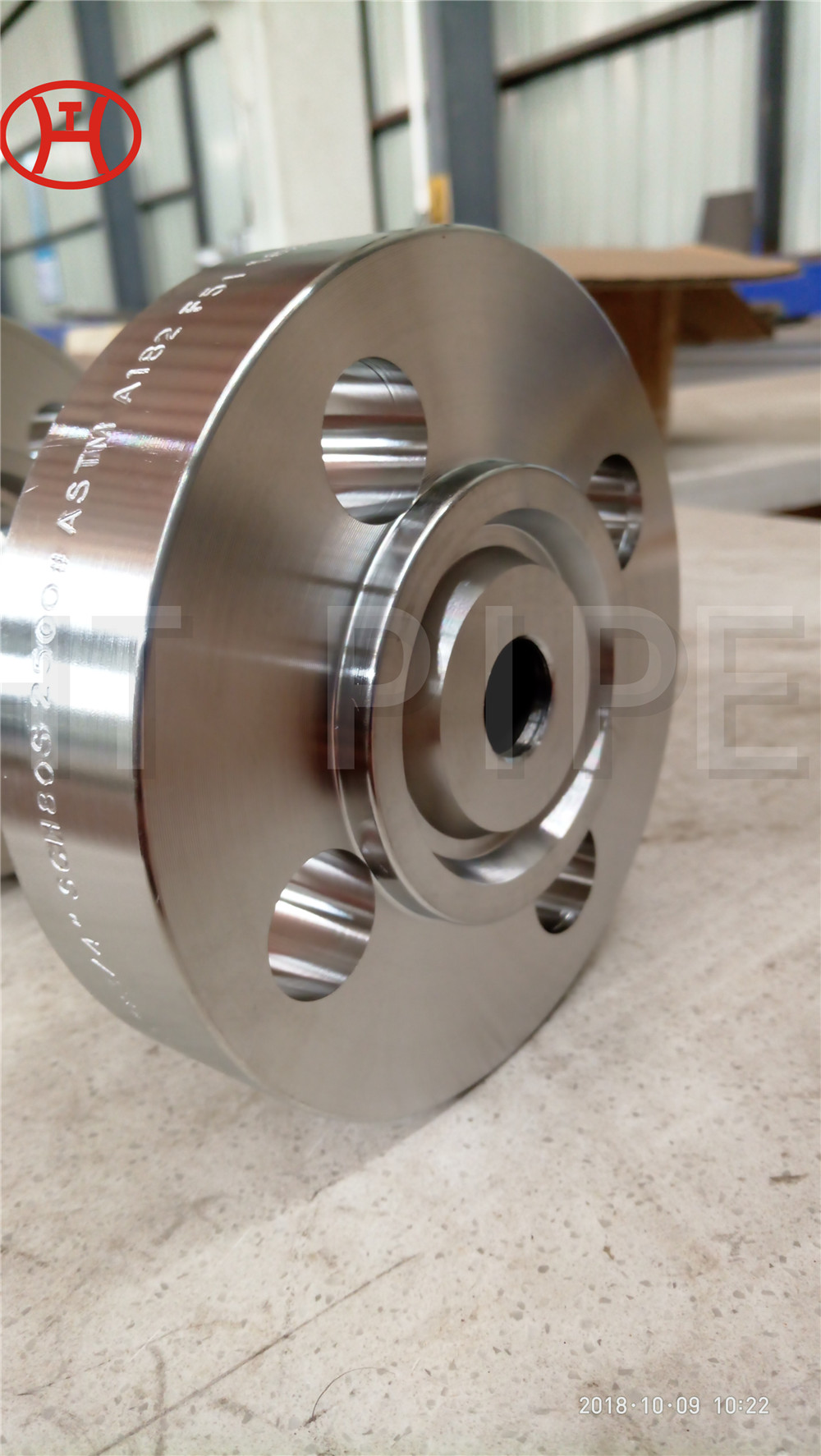

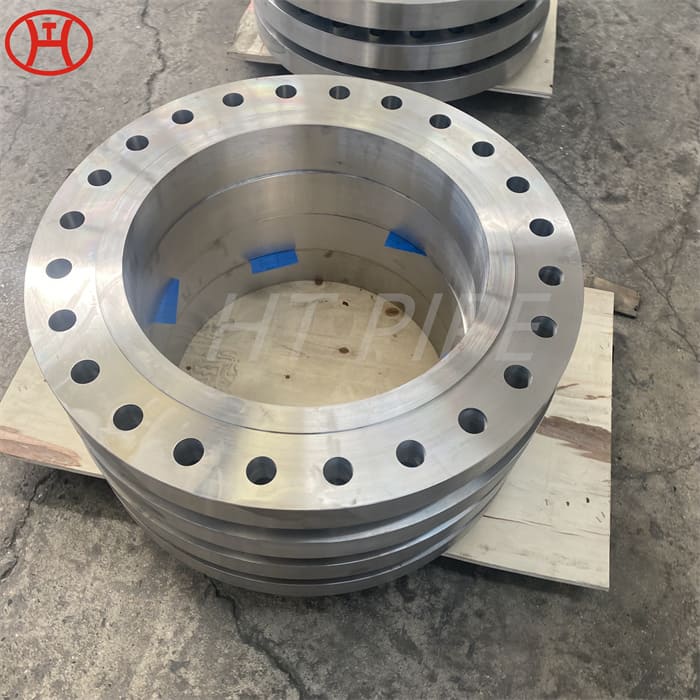

I-flange iyindandatho yensimbi (eyakhiwe, enqunywe kusuka epuletini, noma i-rolled) yakhelwe ukuxhuma izingxenye zepayipi, noma ukujoyina ipayipi kumhlangano wengcindezi, i-valve, iphampu noma omunye umhlangano ovusiwe ovusiwe. Ama-Flanges ahlanganiswe komunye nomunye ngama-bolts, futhi ohlelweni lwamapayipi ngokushiswa noma ngomcucu (noma okuxekethile lapho kusetshenziswa izimbumbulu). I-Finanless yensimbi filange eyenziwe lula njenge-SS Flange, isho ama-flanges enza ngensimbi engenacala. Amazinga ajwayelekile wezinto ezibonakalayo namamaki yi-ASTM A182 Ibanga F304 \ l ne-F316 \ l, libe ngu-2500 njll.

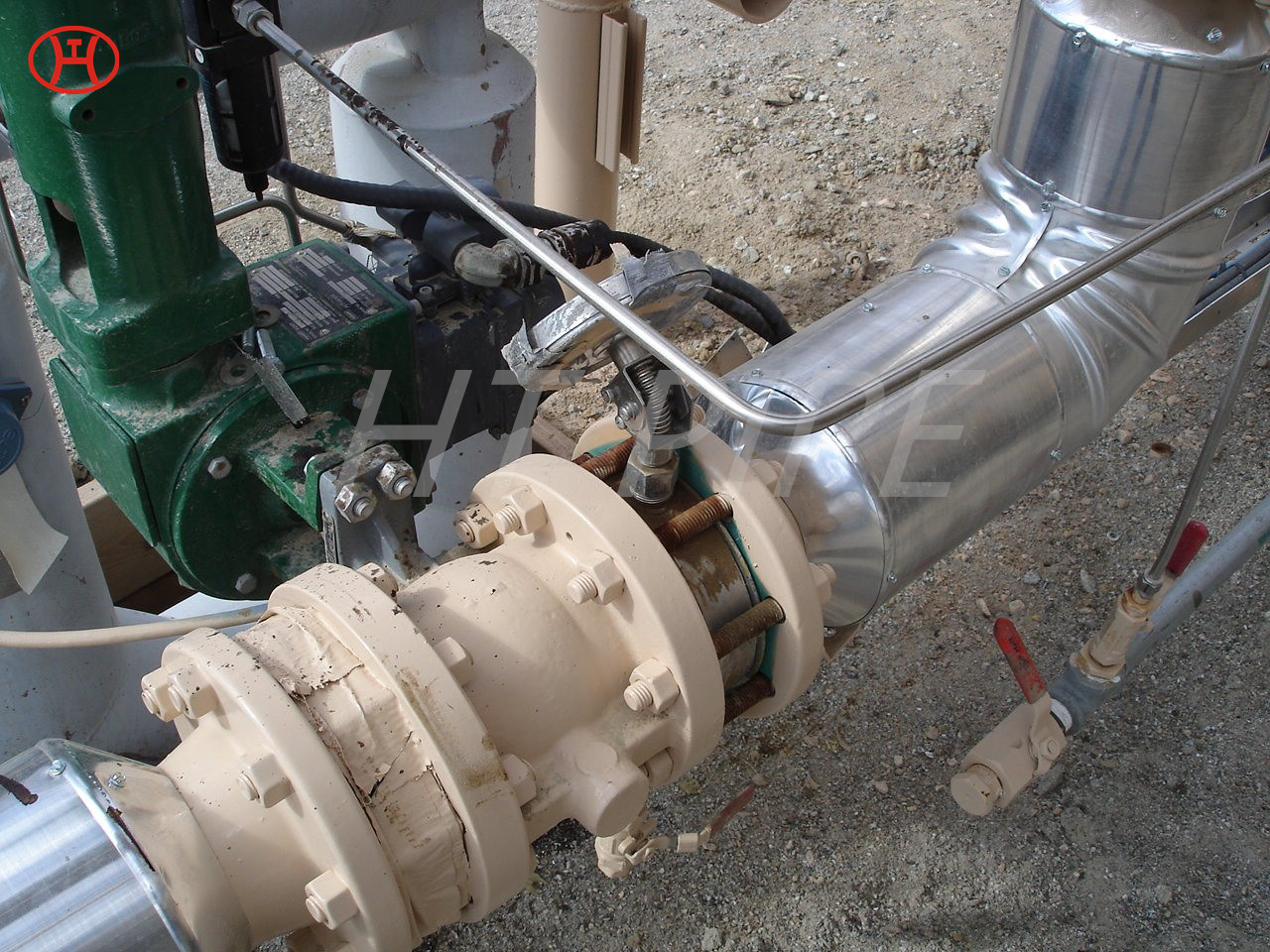

I-Falnge isesibili elisetshenziselwa ukujoyina indlela ngemuva kokushiswa. Ama-Flanges asetshenziswa lapho amalunga edinga ukusatshalaliswa. Inikeza ukuguquguquka kokulungiswa. I-Flange ixhumanisa ipayipi nemishini ehlukahlukene nama-valve. Ama-flanges e-BreakUp angezwa ohlelweni lwePipeline uma kulungiswa njalo ekusebenzeni kwezitshalo. I-Flanged Joint yakhiwa ama-sparate amathathu futhi azimele yize izingxenye ezihlangene; amafuvu, ama-gaskets, kanye ne-bolting; aqoqwe ngelinye ithonya, i-fitter. Izilawuli ezikhethekile ziyadingeka ekukhetheni nasekusetshenzisweni kwazo zonke lezi zinto ukuthola okuhlanganisiwe, okuye kwamukelwa ukuqina okuvuzayo.