Ukumelana kukaHasloy ku-Sulfuric Acid kwenza kube ukukhetha okuvamile ukuvikela kusuka ku-hydrogen sulfide (H2S), kwaziwa kakhulu ngokuthi yi-Sour Gas.

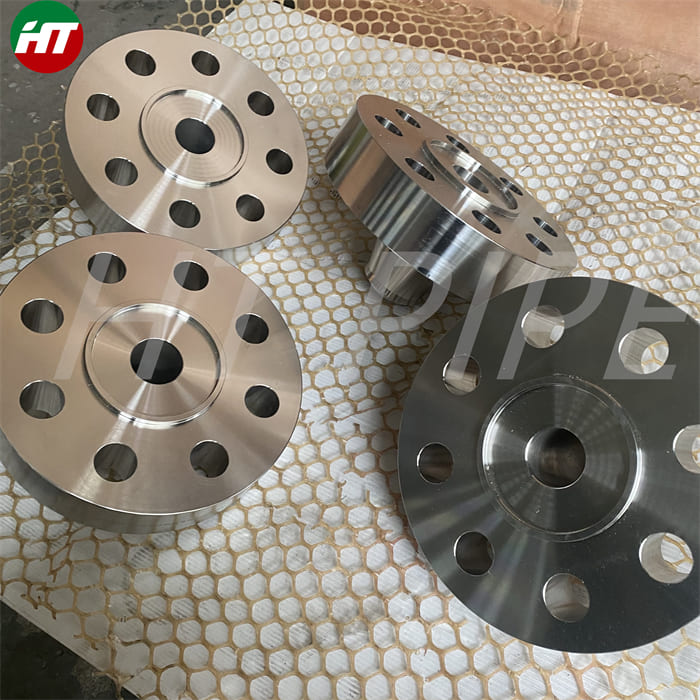

I-Flange ingeyesibili esetshenziswa kakhulu endleleni yokujoyina ngemuva kokuhlakazeka. Ama-Flanges asetshenziswa lapho amalunga edinga ukusatshalaliswa. Inikeza ukuguquguquka kokulungiswa. I-Flange ixhumanisa ipayipi nemishini ehlukahlukene nama-valve. Ama-flanges e-BreakUp angezwa ohlelweni lwePipeline uma kulungiswa njalo ekusebenzeni kwezitshalo.

Kulula ukuwela futhi kungasetshenziswa njengokuthi ngemuva kokushiswa. Ukwakheka kwemvula ye-carbide kumajoyinti we-welded kungaphansi futhi ngenxa yalokho indawo ethintekile ekushiseni ayingathinteki ngokugqwala kolunye uhlangothi. Ngakho-ke impahla ye-DIN 2.4617 imelana nokugqwala okufanayo kanye nokugqwala kwasendaweni ngisho nangemva kokufudumala. Inokumelana okuhle kakhulu ngokuqhekeka kokugqwala kwengcindezelo nokuhlasela kwe-crevice corrosion futhi. Le mikhiqizo ikhiqizwa kulandela wonke amazinga asethwe yizinyunyana ezahlukahlukene ngohlelo. Singabahlinzeki be-Alloy B2 abangenza ngezifiso yonke imikhiqizo yethu ngokwezidingo zakho ngezimo ezahlukahlukene nosayizi. Uma unemibuzo noma ufuna ukwazi kabanzi ngemikhiqizo yethu, xhumana nathi sazi okuningi. Izicelo embonini yenqubo yamakhemikhali ezibandakanya iSulfuric, phosphoric, hydrochloric ne-acetic acid. Ukushisa okusetshenziswa kwemvelo kuyahluka kusuka ekushiseni okukhona ku-1500¡ãf kuya ezindaweni (sicela ushayele izeluleko zobuchwepheshe).