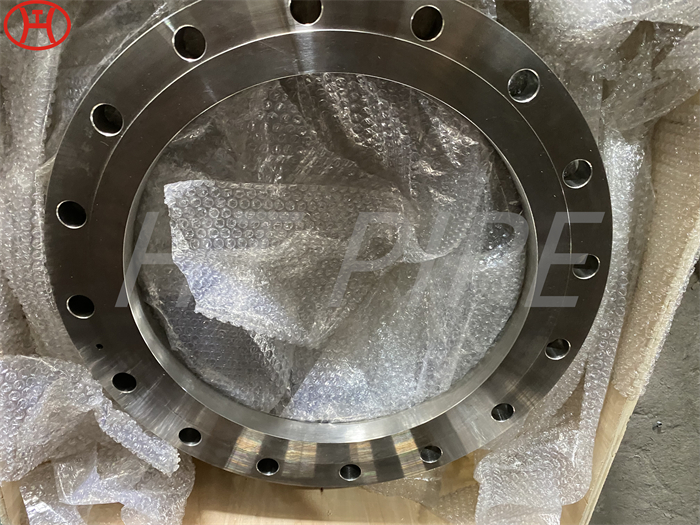

S31254 FLANLES Steel Engagqwali 254 SMO FLANGES

Din975 N083367 Black Natural Insimbi Engagqwali Ibanga 8 ture Rods Throad REGODS CARECEENS Carbon Steel

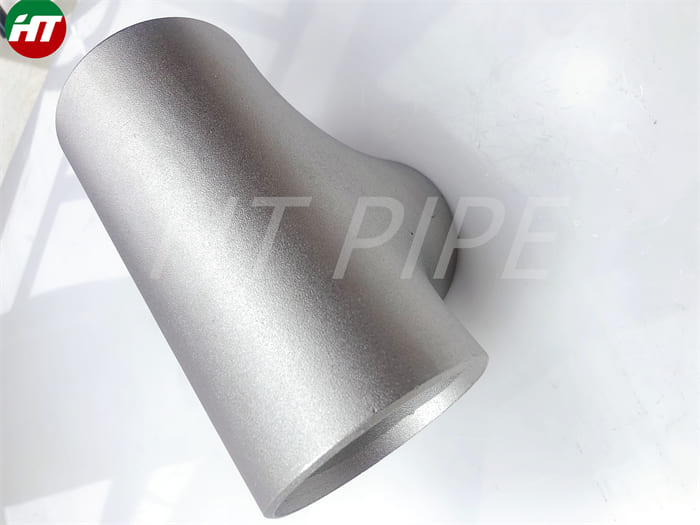

I-Alloy 926 Flange imelana kakhulu nokushisa okuphezulu kunensimbi yendabuko ye-chromium-nickel insimbi engenacala enjengama-304; Okuqukethwe okuphezulu kwe-nickel kwenza kube nokumelana ne-oxidation okungcono kuneleveli engu-18-8 insimbi engenacala, futhi ukumelana kwalo oxidination akunakuphansi kwamabanga aphezulu okushisa okushisa ngo-1900 f (1038 c) alloy. Imvamisa isetshenziswa kumapayipi, amalunga, amasistimu wokugeleza komoya, njll. Ukukhiqizwa kwegesi ye-acid gesi, ama-evfuric acid usawoti, ama-clistalline usawoti, ukugcwaliswa kwezinhlelo ze-crystalline ezitshalweni zendle, Iziqukathi zokuhambisa amakhemikhali awonakalisayo, ukukhiqizwa kwezinto eziphilayo eziphilayo usebenzisa ama-carloride we-chloride we-chloride kanye nezitshalo zokubuyela emuva ze-osmosis.