I-ASTM SA234 WPB Carbon Steel Ukunciphisa Tee

Ukucaciswa kwe-UNS S31803 (ASTM F51) kudluliselwe kakhulu yi-UNS S32205 (1.4462, ASTM F60). Lokhu kukhombisa isifiso sabo sokwandisa izakhiwo zokugqwala kwe-alloy, ngenxa yokuthuthukiswa kwenqubo yokwenza insimbi ye-AOD, okuvumela ukulawulwa okunzima kokwakheka. Ngaphezu kwalokho, kuvumela ukuthonya izinga lesengezo le-nitrogen kunokuba nje likhona njengento yangemuva. Ngakho-ke, amamaki aphezulu aphezulu kakhulu afuna ukukhulisa okuqukethwe kwe-chromium (CR), i-molybdenum (mo) ne-nitrogen (n).

Amapuleti ensimbi namashidi namakhoyili

Kuthunyelwa kwamanye amazwe futhi kukude, okukhuluma ngobuciko bezobuchwepheshe bemikhiqizo yethu. Yaziwa ngezakhiwo zayo ezihlala isikhathi eside, ukumelana nokugqwala, impilo ende nokuningi. Ukufakwa kwezithuthi kwe-Infolment WNR 2.4668 kusetshenziswa abashintshi bokushisa, imithambo yengcindezi, amapayipi, ama-valve, ama-flanges, ama-flanges kanye nokufakwa, ama-condenser, njll.

I-Hastelloy C276 Alloy, uns N10276, 2.4819, iyi-nickel esetshenziswa kakhulu futhi eguquguqukayo yokumelana ne-nickel alloy.

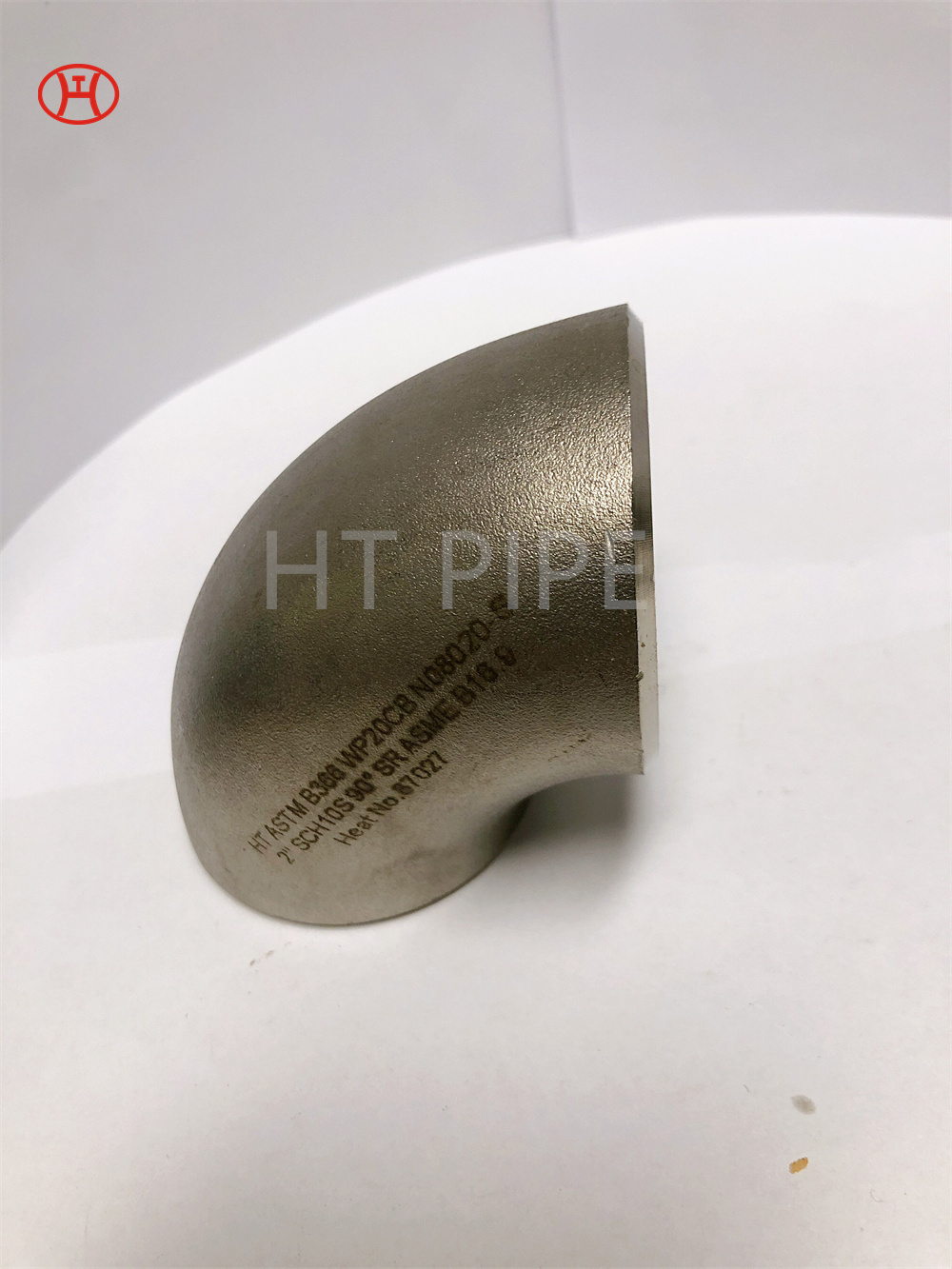

I-ASME B16.28 I-Radius Radius Elbows, i-radius emfushane ye-180-Deg Returns: 1 \

2 "-24" Ubukhulu obudongeni: Sch5S-Schxxs

I-strong ne-oxidation imelana ne-2200 deg. F (1200 Deg. C) - I-Hastelloy X Pipe Bend yisisombululo esiqinile esiqinisiwe esiqinisiwe sinamandla amahle kanye nokumelana ne-oxidation kuze kube ngu-2200 deg. F (1200 deg. C).

I-ASME B16.49 30¡Ã 45¡Ã 60¡Ã9¡Ã 90¡Ã♥ 60¡Ã♥

I-ISO, DIN, JIS Zonke izinhlobo zomkhiqizo we-buttwelding noma njengomdwebo wekhasimende njengesidingo seklayenti