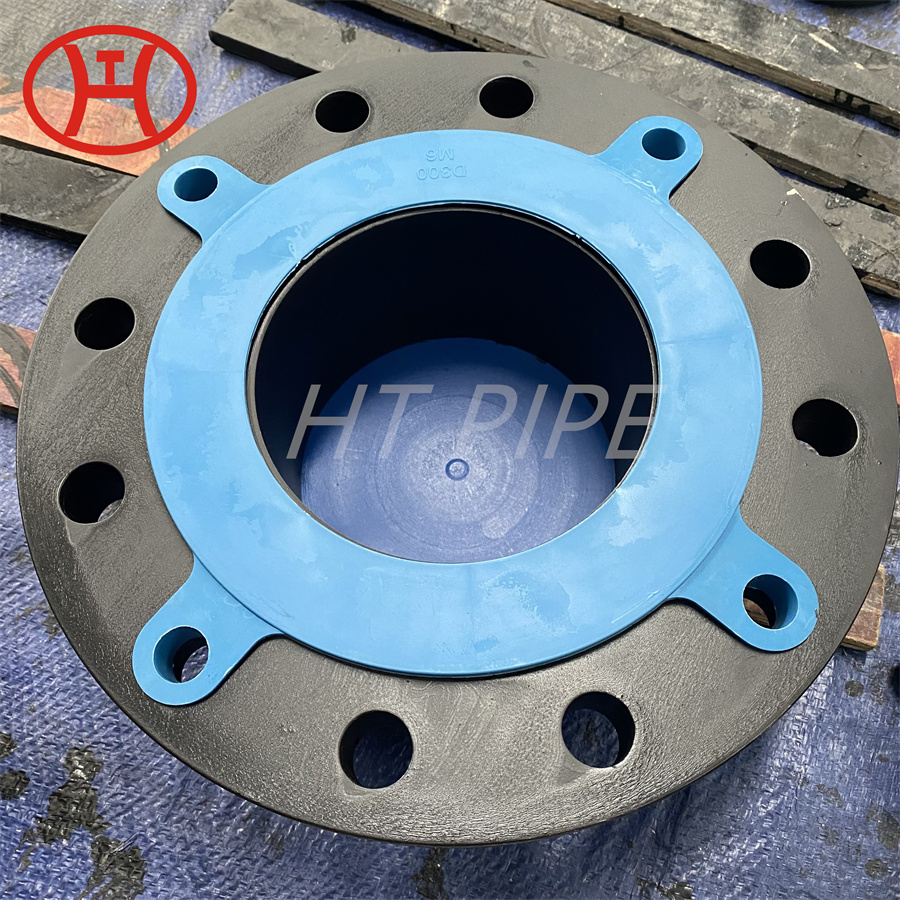

ansi b16.5 A350 LF2 welded carbon steel neck flange

The main difference between carbon steel A350LF2 ferrule flanges and other austenitic steels is the higher hardness of carbon steel alloys.

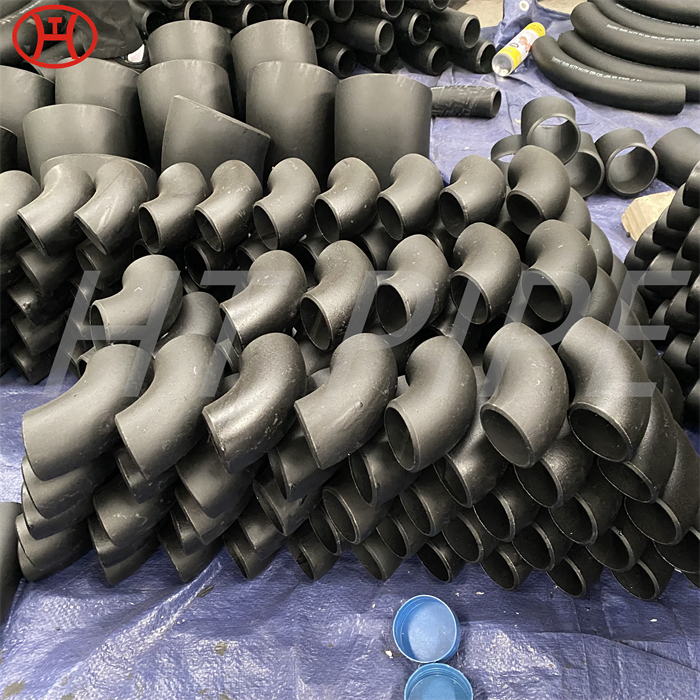

Carbon Steel A350 LF2 Socket Weld Flanges are typically serviced at 500¡ãC – 550¡ãC. Carbon steel alloy A350 LF2 flanges are mostly annealed and stress relieved by cold working processes such as rapid cooling in water or air. Carbon Steel A350 LF2 Butt Weld Flanges are often used to develop properties that tend to come into play during heat treatment. For an alloy to be used at low temperatures, it needs to have certain properties to prevent failure. At low temperatures, metals tend to shrink – because the volume between the atomic spaces decreases. In piping systems, constricted spaces caused by components are inefficient because they restrict the flow of media through the piping. It’s us who make blind flanges at the ends of pipes to stop them from flowing. We manufacture low temperature carbon steel A350 Lf2 blind flanges. You can use these to more easily do things like inspect pipes and get them out. We manufacture A350 Gr Lf2 Grade 1 butt weld flanges with some strength and can withstand some damage.