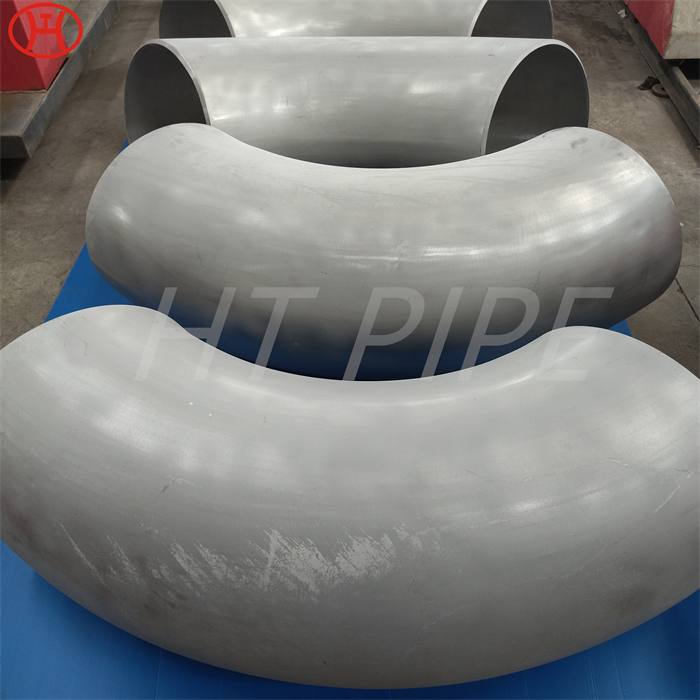

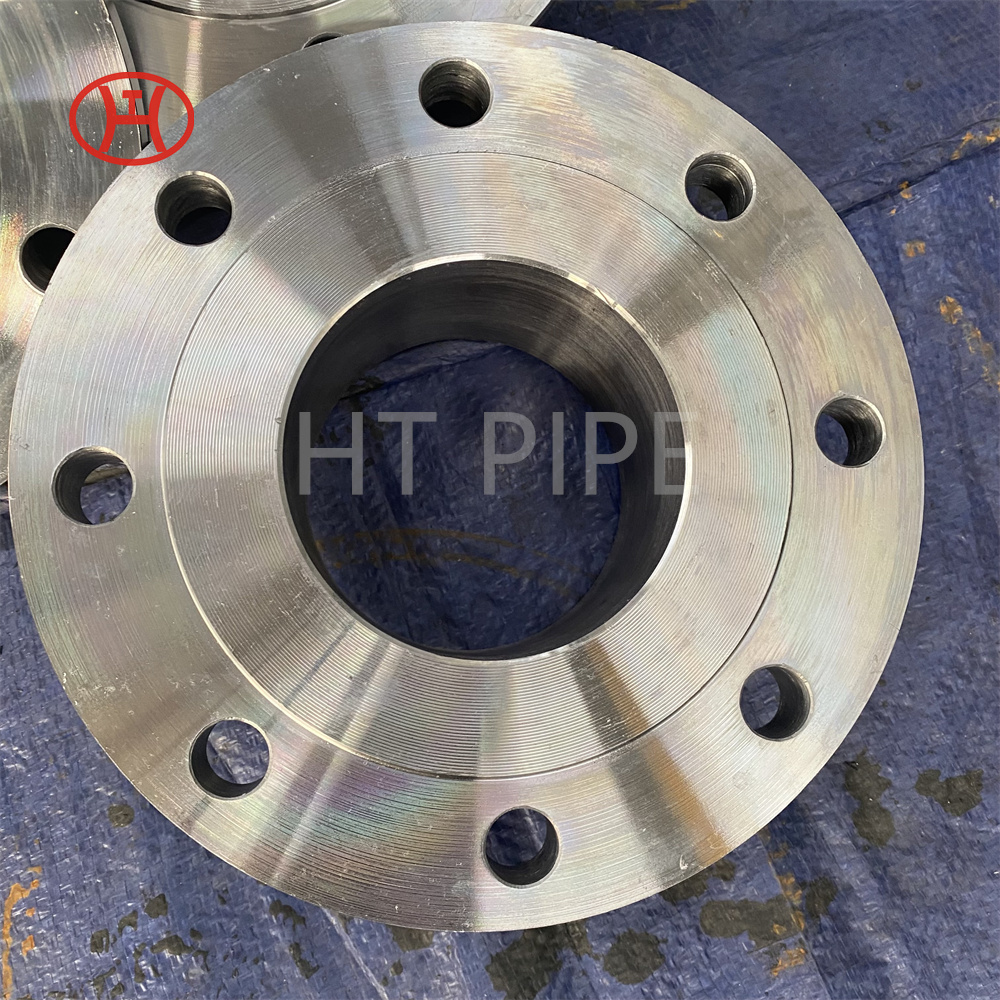

37 or 45 degree nickel alloy angle round tube flange N07718 flange

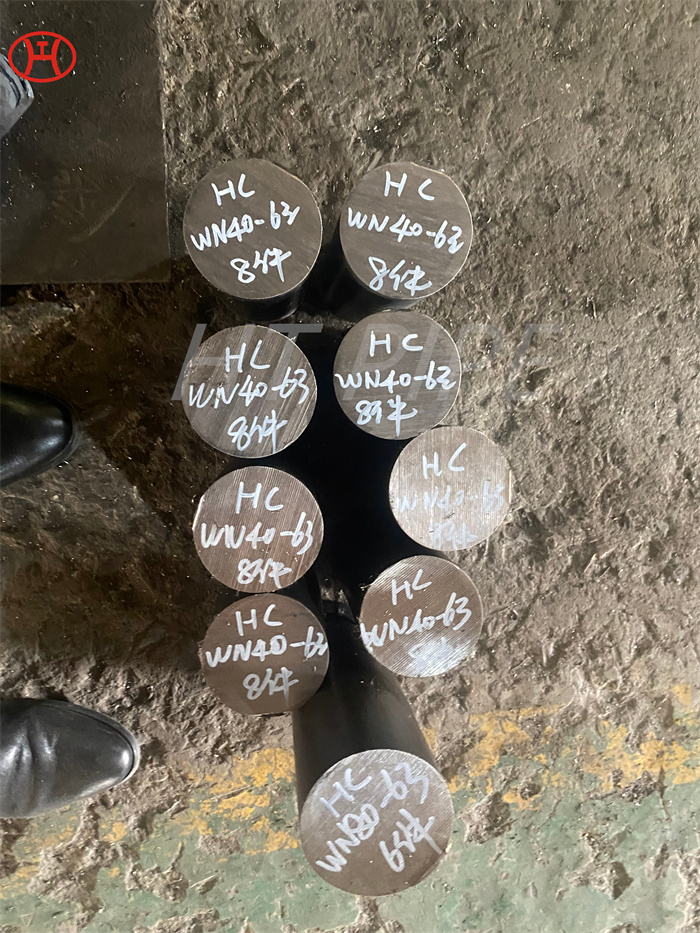

Inconel 718 alloy ranks first among deformed superalloys in yield strength below 650°C, and has good fatigue resistance, radiation resistance, oxidation resistance and corrosion resistance, as well as good workability, weldability and long-term structural stability , can manufacture various shapes of complex parts, in the aerospace, nuclear energy, petroleum industry, has been widely used in the above temperature range.

Another feature of Inconel 718 alloy is that the alloy structure is particularly sensitive to hot working processes. By mastering the rules of precipitation and dissolution in alloys and the relationship between structure, process and performance, reasonable and feasible process procedures can be formulated according to different use requirements, and various parts with different strength grades and use requirements can be met.

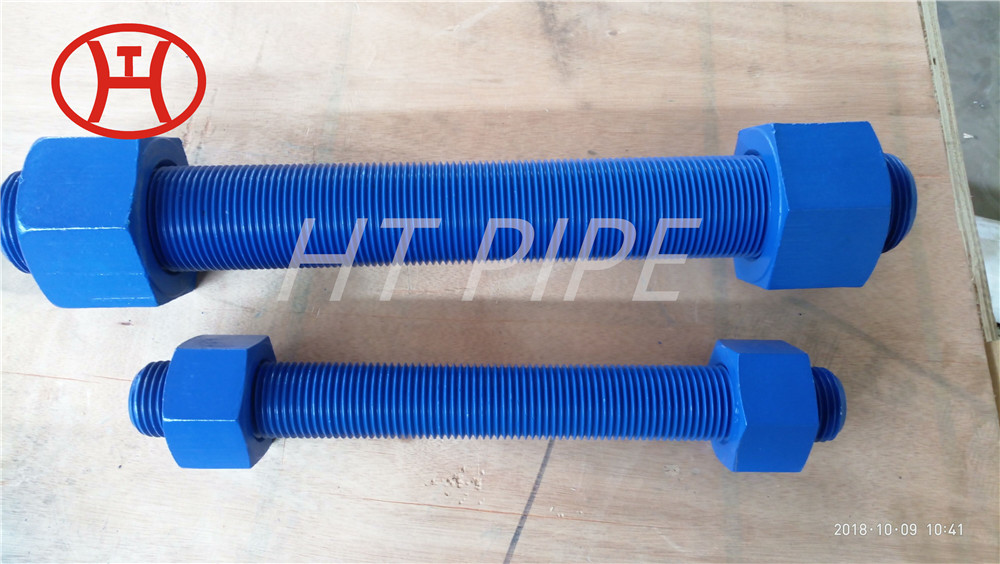

Meanwhile, UNS N07718 Inconel flanges are the most common hardenable Inconel grade. This precipitation hardening nickel-chromium alloy combines excellent corrosion resistance with high strength at elevated temperatures. This alloy is approximately twice as strong as Inconel grade 625, has excellent creep rupture strength at temperatures up to 1300°F (700°C), and can be used at temperatures up to 1800°F (982°C) . The Inconel 718 stage is commonly used in gas turbines, rocket engines, spacecraft, nuclear reactors, pumps and tools.