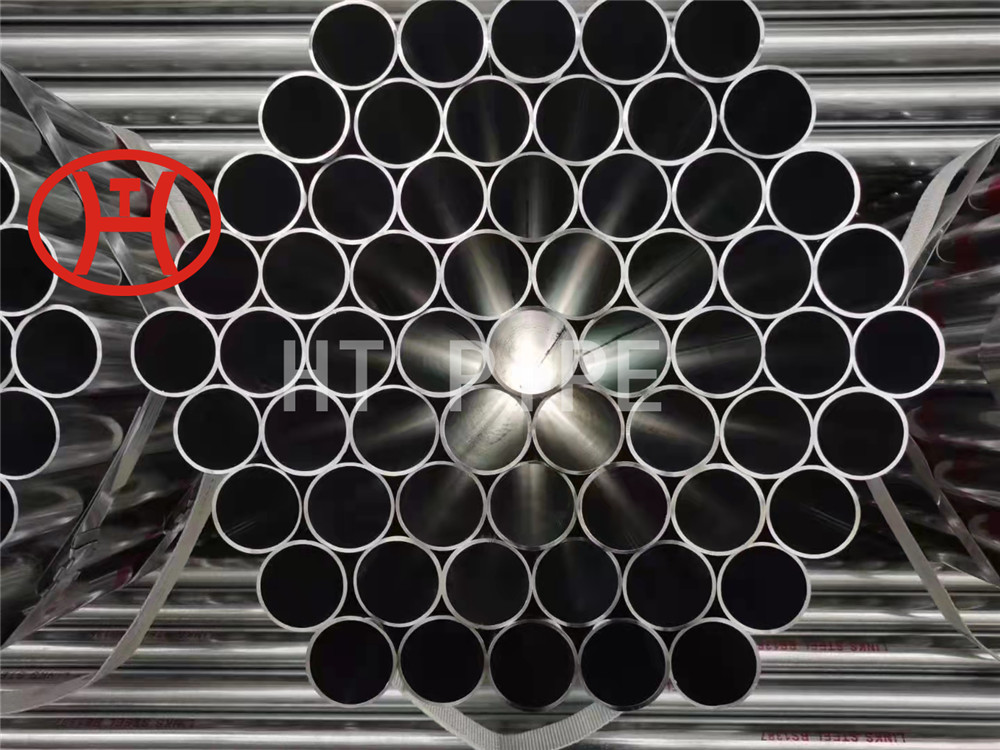

nickel alloy pipe UNS N08020 alloy 20 tube ASTM B474 smls pipe in stock

Nickel alloys are some of the most useful materials for manufacturing technically superior pipes and tubes for industrial applications. Their inherent properties make them viable for a wide range of uses. Nickel alloys are exceptionally corrosion resistant and can be used in high-temperature environments.

The most commonly used standard for Alloy 20 seamless pipes is ASTM B729. This specification covers seamless pipes that are designed for general corrosion-resisting and low or high-temperature service. Other standards include ASTM B464, ASTM B468, and ASTM B474.

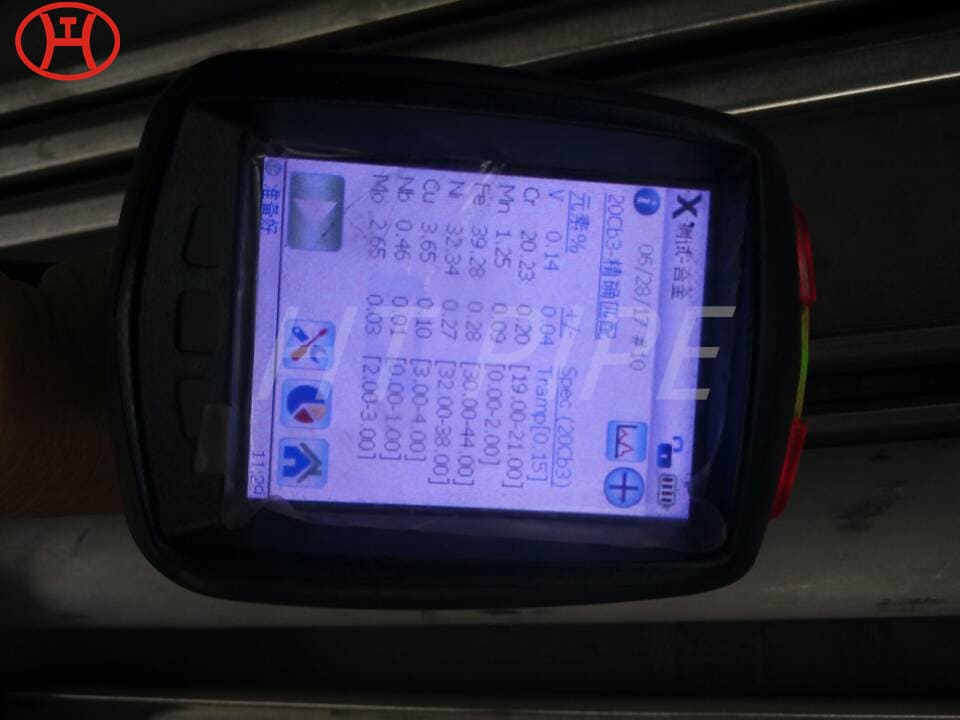

Alloy 20 seamless pipes are made by using the extrusion process, where a heated billet is forced through a die to form a tube. The tubes are then cold-drawn to achieve the desired dimensions. The pipes are subject to various testing and inspection procedures, including visual inspection, ultrasonic testing, eddy current testing, and hydrostatic testing.

Type Seamless Pipe

Seamless Tube

Welded Pipe

Welded Tube

SAW LSAW ERW EFW

Beveled End, Plain End”

Size OD: 1 2″” ~48″”

Thickness: SCH5~SCHXXS

Length :As per your requirement.”

Manufacturing technique Hot rolling Hot work ,Cold rolling

Producing Standard ASME B36.10 ASME B36.19

Material Nickel Alloy ASTM B474 UNS N02200 Ni 200, UNS N02201 Ni201, UNS N04400 Monel 400, UNS N06002 Hastelloy X, UNS N06022 Hastelloy C22, UNS N08825 Incoloy 825 ,UNS N10276 Hastelloy C276, UNS N10665 Hastelloy B2, UNS N10675 Hastelloy B3, UNS N06600 Inconel 600 ,UNS N06601 Inconel 601 ,UNS N06625 Inconel 625 ,UNS N08020 Alloy 20

ASTM B161 UNS N02200 Ni 200, UNS N02201 Ni201