Steel pipes p11 astm a335

Pipes made of SA335 p11 material are commonly used in a variety of applications in different plants and processes around the world. For example, applications for SA335 grade p11 tubing include power plants, petrochemical plants, refineries, hydrocrackers, cokers, reheat pipelines, distillation, oilfield services, high temperature and ultra-high temperature pipelines, and more.

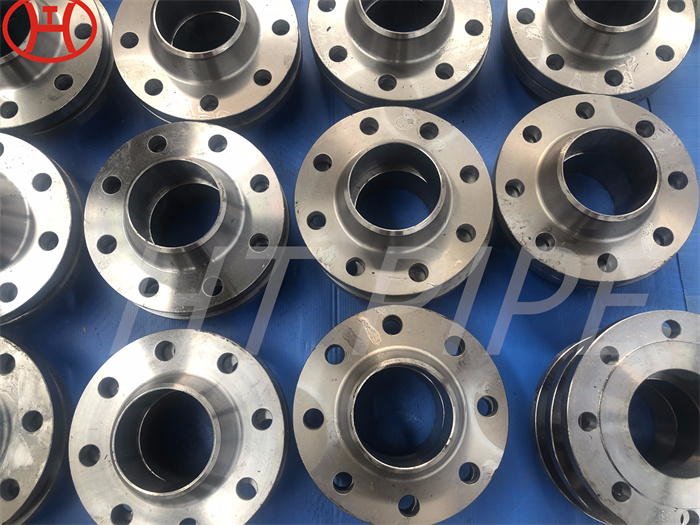

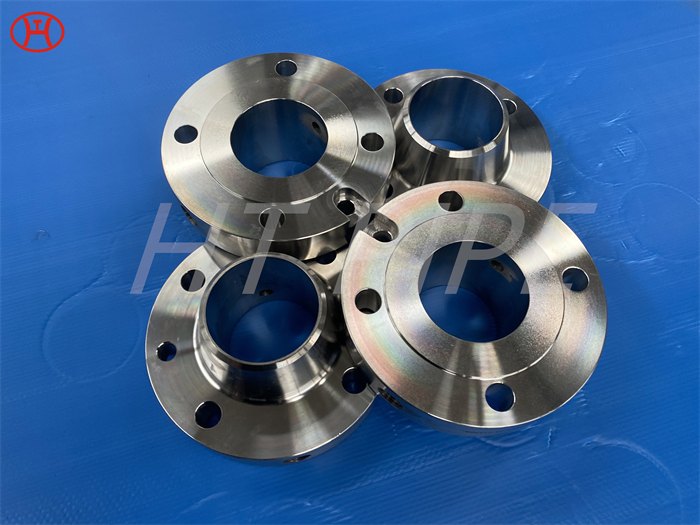

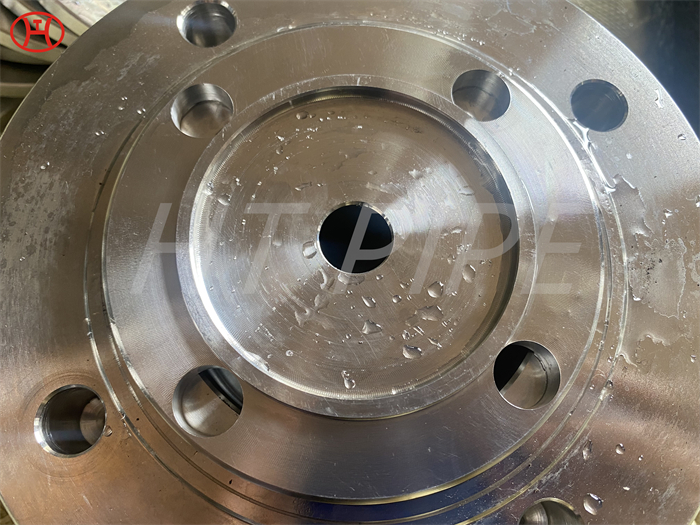

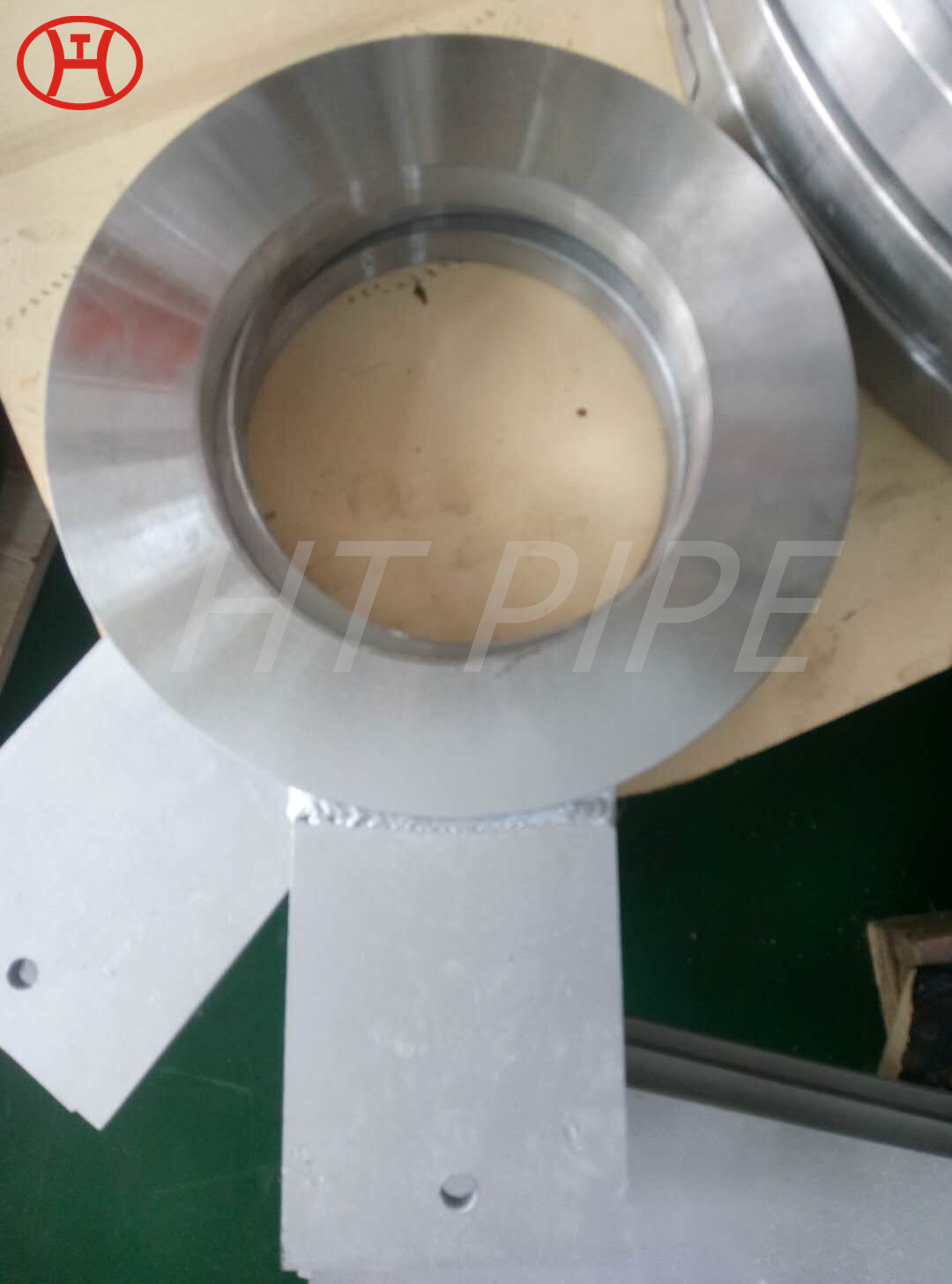

A335 specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding.

ASTM A335 Pipe (ASME S/A335, Chorme-Moly) is a seamless ferritic Alloy-Steel Pipe for high temperature service. ASTM A335 Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Sometimes referred to as “P Grade”, chome moly pipe is popular in P-Grades P5, P9, P11, P22, and P91. The most common use of grades P11, P22, and P91 is in the power industry and petro-chemical plants, Grades P5 and P9 are commonly used in refineries.

ASTM A335 Pipe is often called chrome moly pipe because of the chemical makeup of Molybdenum (Mo) and Chromium (Cr). Molybdenum increases the strength of steel as well as the elastic limit, resistance to wear, impact qualities, and hardenability. Moly increases the resistance to softening, restrains grain growth and makes chromium steel less susceptible to embrittlement. Moly is the most effective single additive that increases high temperature creep strength. ASTM A335 Pipe also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel pipe make ASTM A335 Pipe ideal for use in power plants, refineries, petro chemical plants, and oil field.

ASTM A335 Seamless Steel Pipe Specifications:

- Name: ASTM A335 alloy steel pipe

- Diameter:16-1016mm

- Thickness: 2—120mm

- Steel grade: P1 P2 P5 P9 P11 P12 P22

- Surface: oiled, black painted to prevent rust

- APPLICATION Fileds:Industrial Boilers, Power Plants, Nuclear Plants