P91 boiler tube ASME A335 P91 Pipe stockist

The achievable mechanical properties depend on added elements such as nickel, chromium, molybdenum and vanadium. The following are a series of improved properties of alloy steel (compared to carbon steel): strength, hardness, toughness, wear resistance, corrosion resistance, hardenability and hot hardness. To achieve some of these improved properties, the metal may require heat treatment.

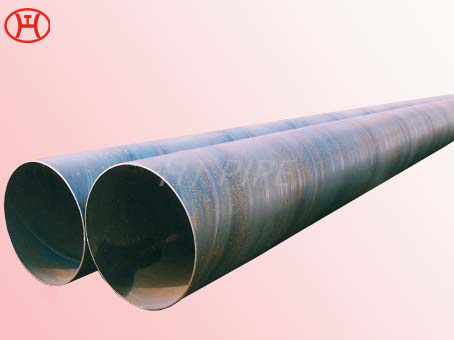

EXPORTER A335 GR P91 WELDED PIPE, BUY P91 ALLOY STEEL SEAMLESS PIPE and ASME SA 335 ALLOY STEEL P91 CHROME MOLY PIPES

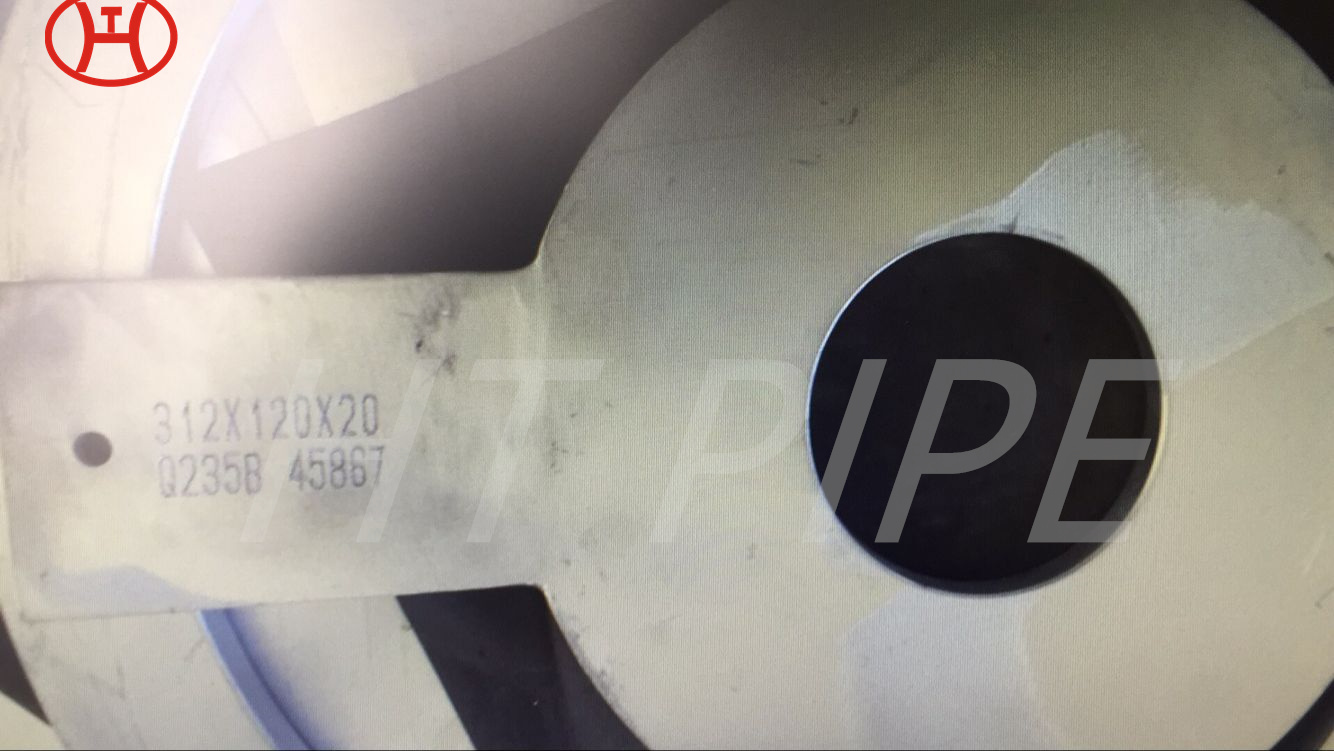

HT PIPE is reliable ASTM A335 P91 Pipe Suppliers in China, it properties consist the mixture of 1 % Molybdenum and 9 % Chromium. As a result of Molybdenum being present, the creep resistance of the ASME SA335 P91 material is increased and due to the presence of Chromium, its oxidation resistance is increased as well as there is increase in high temperature strength and Astm A335 P91 Temperature Limit. Small Proportion of Manganese and Nickel are present in it. The Chemical Composition of A335 P91 Seamless Pipe is Manganese 0.30 – 0.60, Silicon (max.) 0.50, Chromium 4.00- 6.00, Carbon (max.) 0.08 – 0.12, Phosphorus (max.) 0.025 and Molybdenum 0.45-0.65.

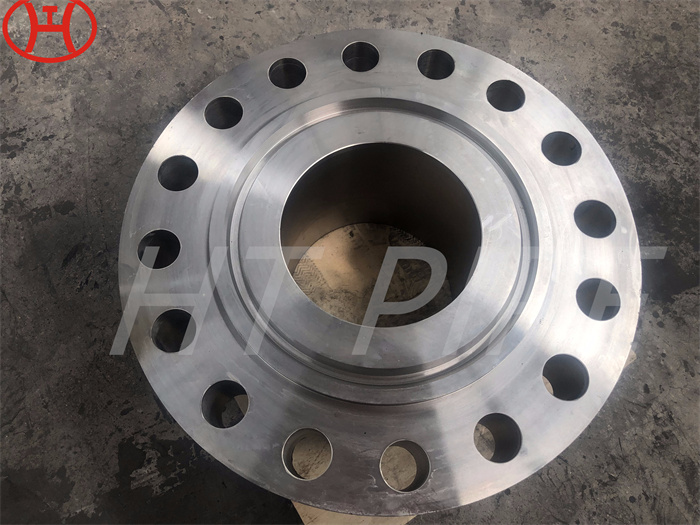

The manufacturing procedure of ASME SA335 P91 pipe starts with its forming by either cold drawing or hot finished followed by heat treatment. The heat treatment begins with the process of normalizing the A335 P91 pipe at 1050 °C followed by cooling down by air at 200 °C and then tempering at about 760 °C. The manufacturing process makes the astm a335 P91 alloy steel pipe well suited to forming, bending, flanging, and fusion welding.

Molybdenum increases the overall strength, resistance, elasticity, hardenability and overall quality, moly ensures that A335 P91 pipe is more resistant to softening, restrains the growth of grains and lessens the chances of embrittlement. A335 P91 pipe is the single additive that is responsible for the increase in high temperature resistance (to 540-750°C) and it also improves the corrosion resistance to steel.