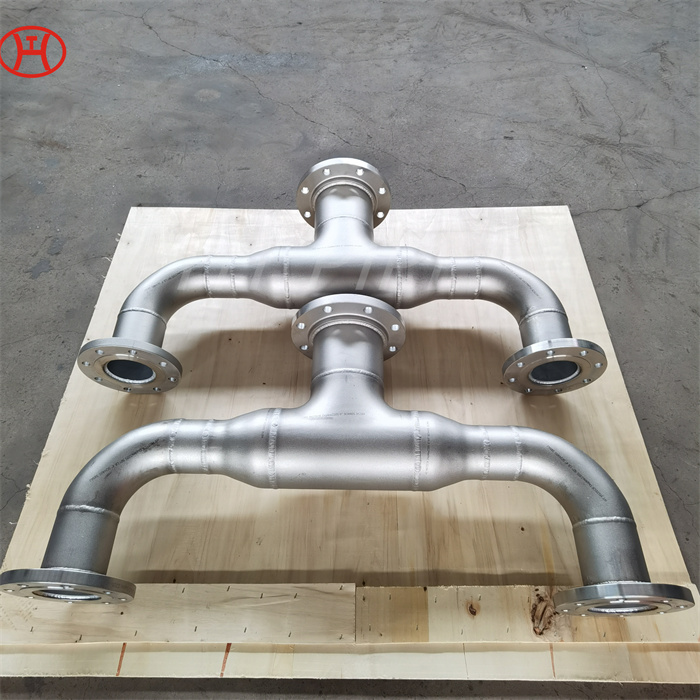

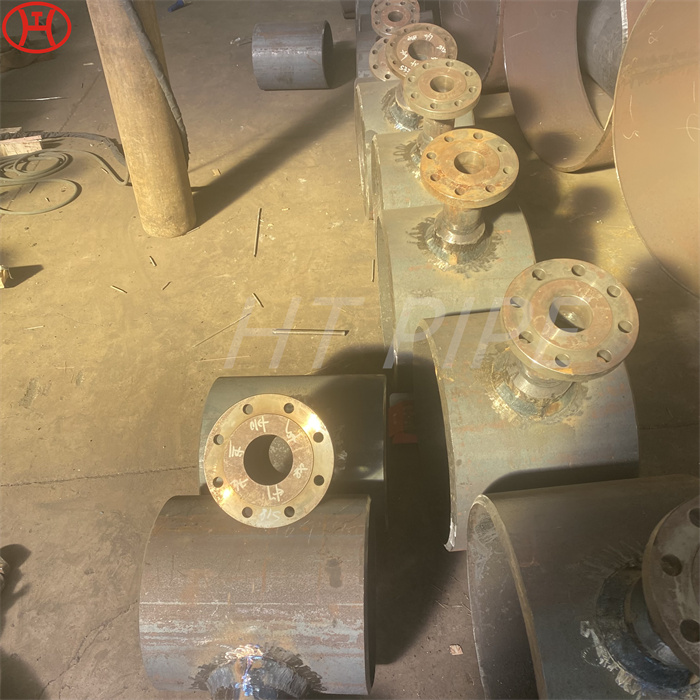

ASTM B366 Nickel Alloy C276 ASME B16.9 90 Degree Elbows

In order to convey the pipeline, it is necessary to remove the straight hose in the pipeline. When using various pipelines, various pipelines must be used. When the pipeline is used, the elbow must be used to change the size of the pipeline. When bifurcating, the three-way pipe The flange connection used when the joint is used with various pipe joints, in order to reach the long-distance transmission pipeline, in order to reach the thermal expansion and cold contraction joint or effective connection aging of the pipeline, the long-distance expansion and cold contraction joint is used for the connection of the pipeline. , In the connection of various instruments, there are also the connectors and plugs of the instrument phase.

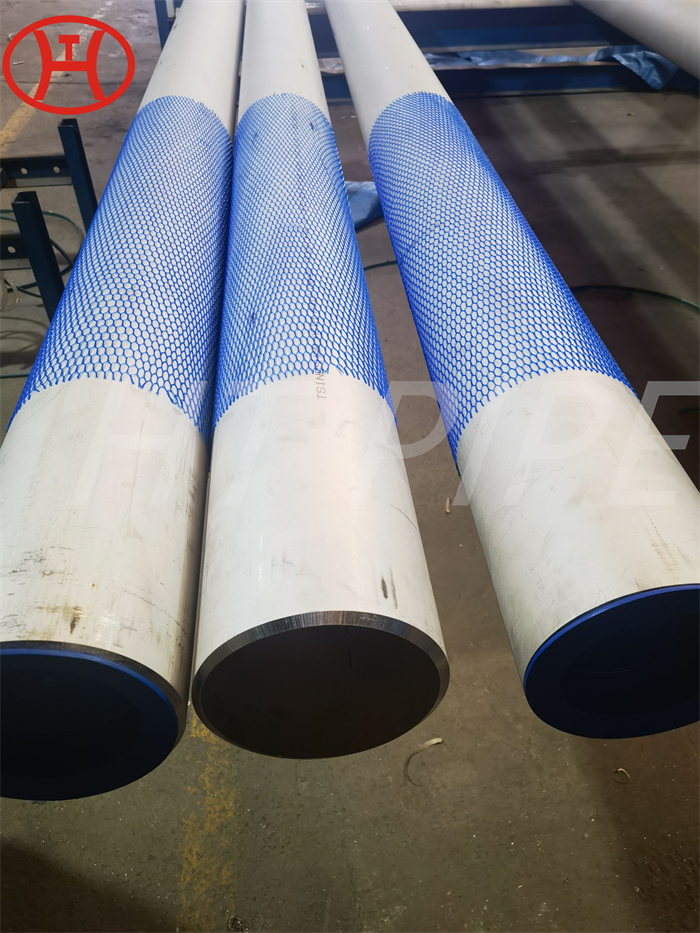

HASTELLOY C276 is a Nickel-chromium-molybdenum wrought alloy that is considered the most versatile corrosion resistant alloy available. This alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process applications in an as welded condition. Alloy C-276 also has excellent resistance to pitting, stress-corrosion cracking and oxidizing atmospheres up to 1900¡ãF. Alloy C-276 has exceptional resistance to a wide variety of chemical environments.

This alloy is also one of the top performing materials for use in oilfield applications, especially

in the recovery and handling of ¡°sour¡± natural gas, which contains hydrogen sulfide and carbon dioxide

and chlorides. The high nickel, chromium and molybdenum content of Alloy C276 make it extremely

resistant to these environments.