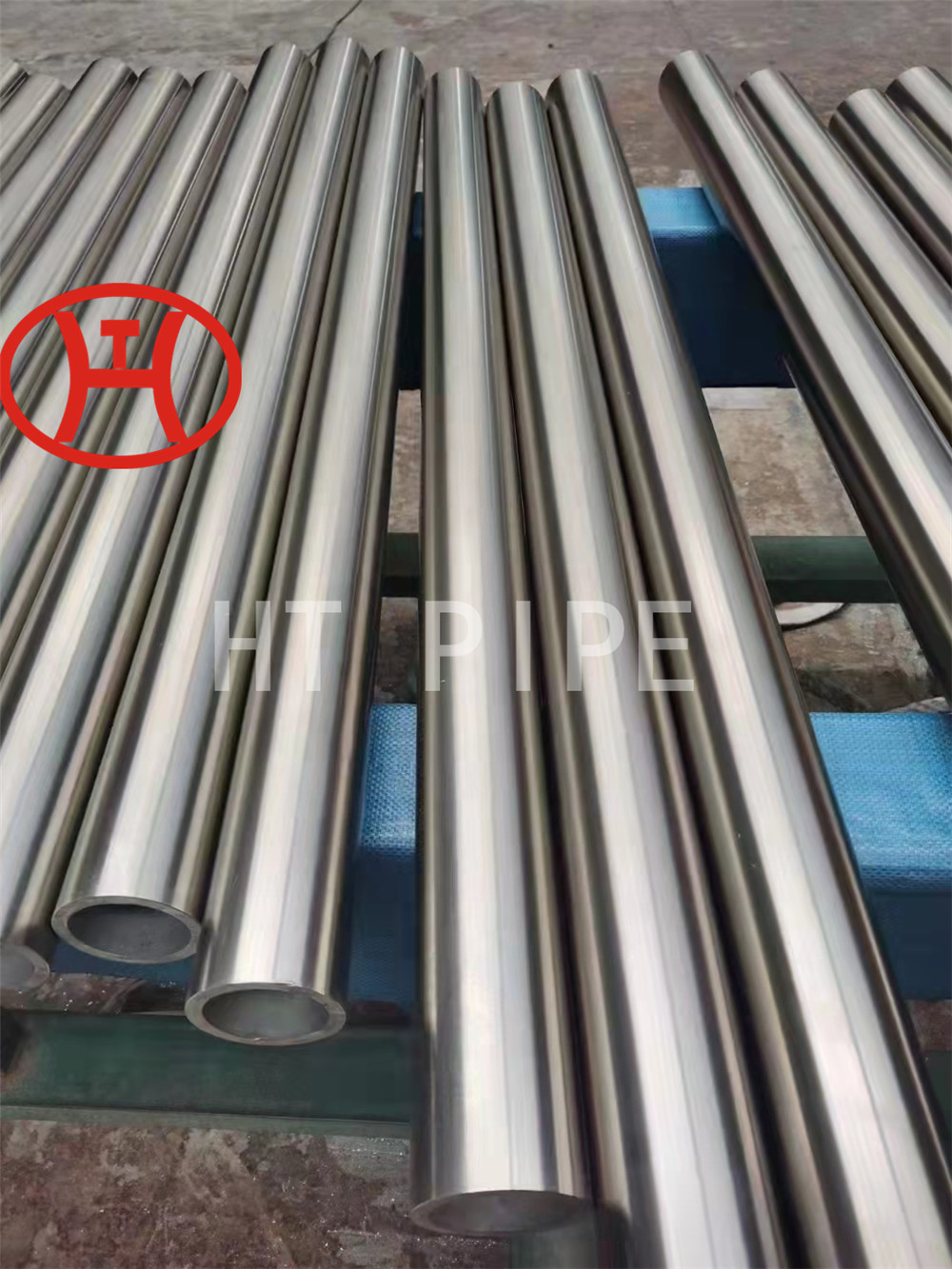

Stainless steel pipe 316L pipe seamless steel pipe in stock

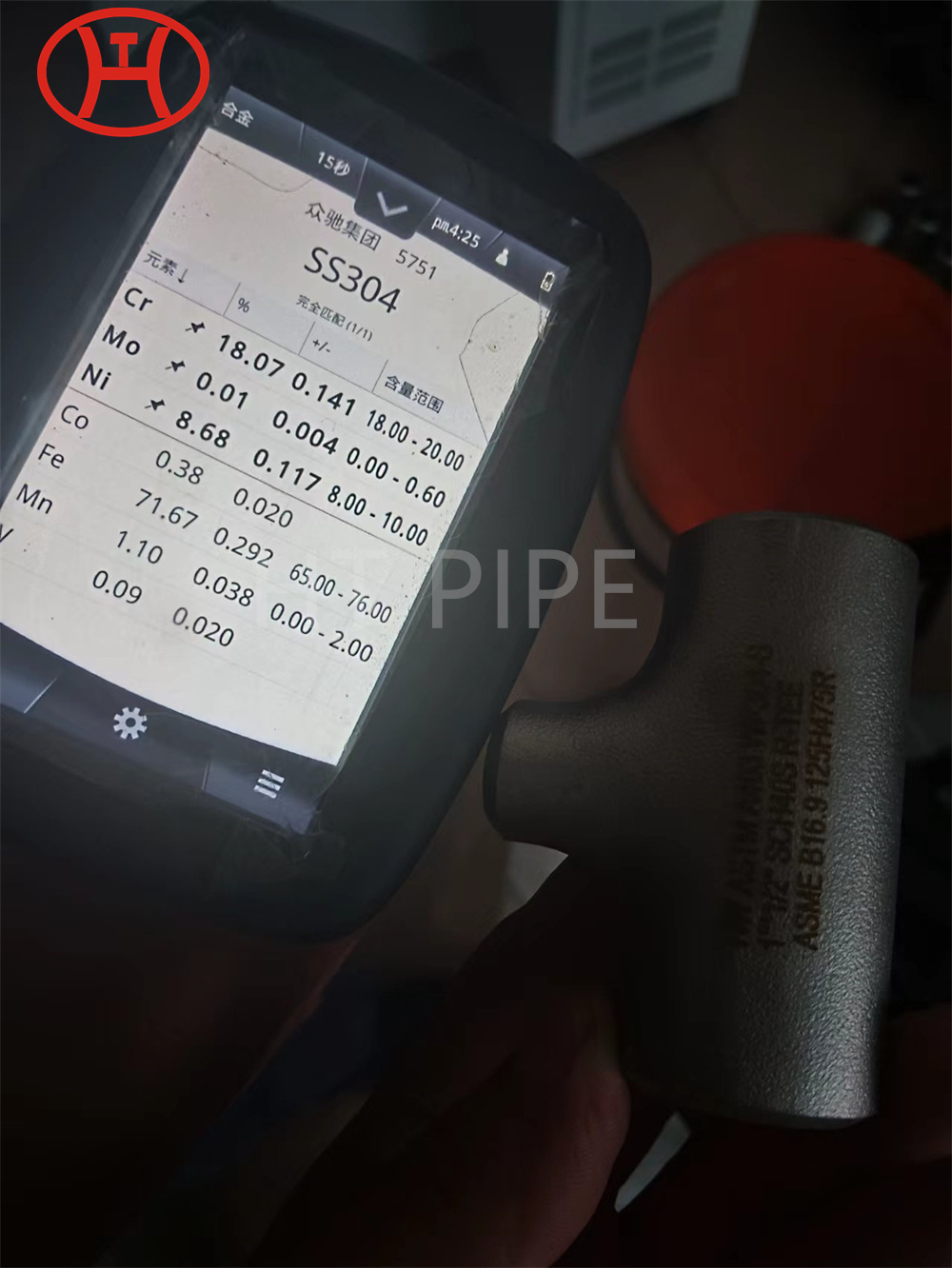

Stainless steel is an alloy of iron that is resistant to rusting. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel’s resistance to corrosion results from the chromium, which forms a passive film that can protect the material and self-heal in the presence of oxygen.

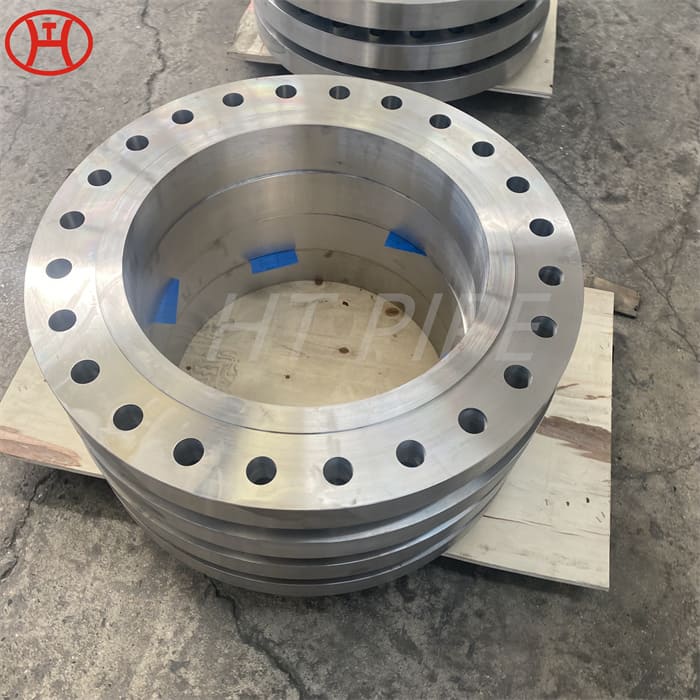

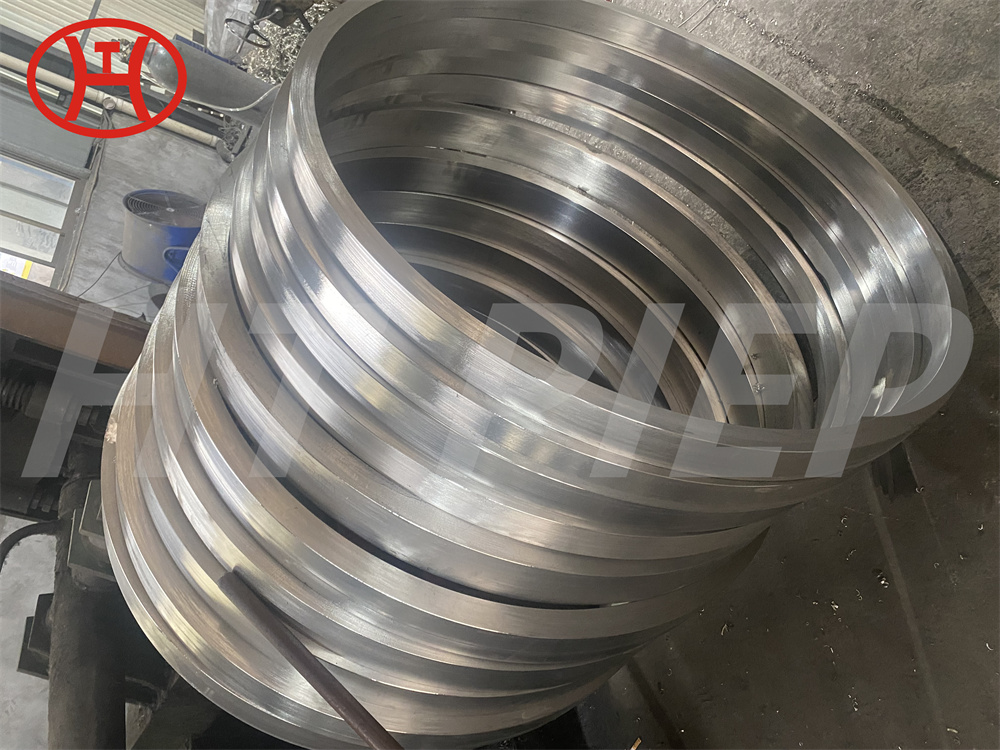

A stainless steel pipe system is the product of choice for carrying corrosive or sanitary fluids, slurries and gases, particularly where high pressures, high temperatures or corrosive environments are involved. As a result of the aesthetic properties of stainless steel, pipe is often use in architectural applications.

Stainless steel pipe can generally be defined as a heavy wall thickness tubing, with dimensions as specified by the American National Standards Institute (ANSI). Pipe dimensions are nominated by outside diameter indicated by the NPS (imperial) or DN (metric) designator and sometimes referred to as the ¡®nominal bore¡¯ ¨C and wall thickness, is determined by the schedule number. The standard ASME B36.19 covers these dimensions.

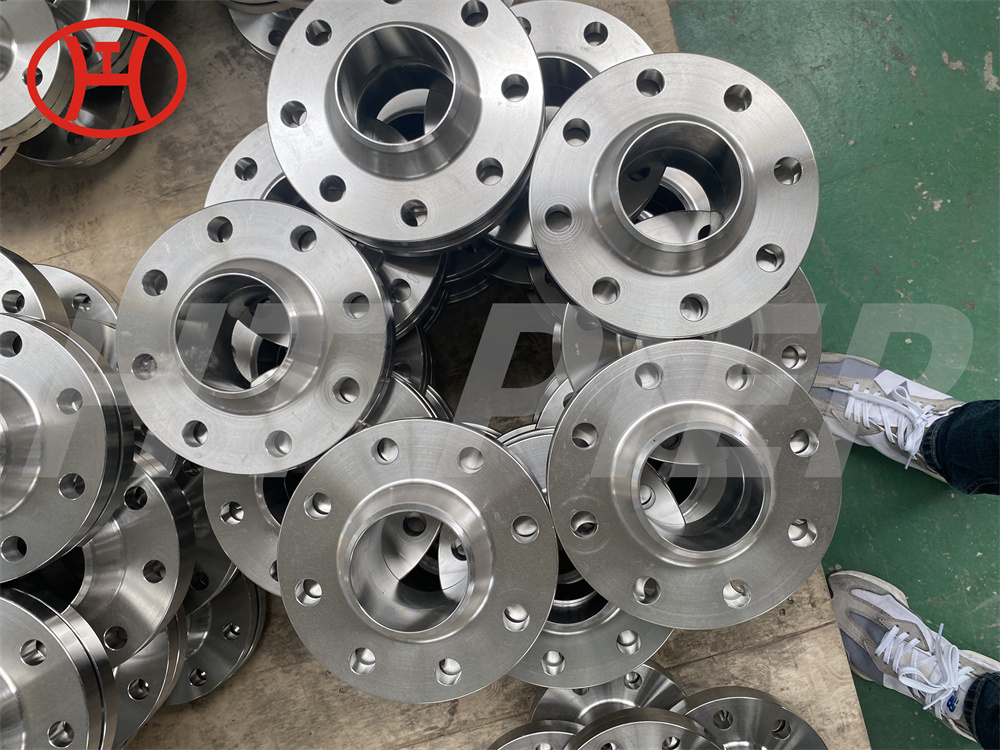

Stainless steel pipe and fittings are supplied in the annealed condition to facilitate fabrication and ensure best corrosion resistance. Atlas Steels can also supply stainless steel pipe with an abrasive polished finish suitable for architectural applications.

The resistance to corrosion and luster are used many applications. Stainless steel can be rolled into sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products.