UNS N08367 Seamless Tube AL6XN Welded Tube

UNS N08367 also commonly referred to as alloy AL6XN is a low carbon, high purity, nitrogen-bearing “super-austenitic” nickel-molybdenum alloy with excellent resistance to chloride pitting and crevice corrosion.

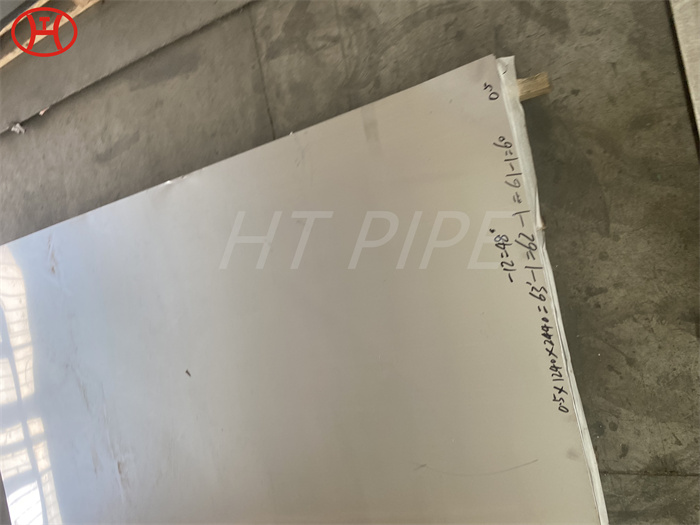

AL-6XN Tube, UNS N08367 Seamless Tube, AL6XN Welded Tube, ASTM B676 UNS N08367 Tube, AL6XN Alloy Tube Nominal Tube

AL-6XN Tube’s high strength and corrosion resistance makes UNS N08367 Seamless Tube a better choice than the conventional duplex stainless steels and a cost effective alternative to more expensive nickel-base alloys where excellent formability, weldability, strength and corrosion resistance are essential. The AL-6XN (UNS N08367) tube carries goes through a rigid inspection process meeting ASTM A270, ASME SA249, and ASME SB676 specifications. AL6XN Welded Tube is widely accepted in pharmaceutical, biotechnology, personal and home care, food, beverage, and dairy processes.

AL-6XN alloy (UNS N08367) is a low carbon, high purity, nitrogen-bearing “super-austenitic” stainless alloy. The ASTM B676 UNS N08367 Tube was designed to be a seawater resistant material and has since been demonstrated to be resistant to a broad range of very corrosive environments. The high strength and corrosion resistance of the AL6XN alloy make AL6XN Alloy Tube Nominal Tube a better choice than the conventional duplex stainless steels and a cost effective alternative to more expensive nickel-base alloys where excellent formability, weldability, strength and corrosion resistance are essential.

Chemical Composition, %

| Ni | Cr | Mo | C | N | Mn | Si | P | S | Cu | Fe |

| 23.5-25.5 | 20.00-22.00 | 6.00-7.00 | 0.03 Max | 0.18-0.25 | 2.0 Max | 1.00 Max | .040 Max | 0.03 Max | 0.75 Max | Remainder |

ASTM Specifications

| Pipe Welded | Tube Welded | Sheet/Plate | Bar | Flanges & Fittings |

| B675, A312 | B676, A249 | B688, A240 | B691, A479 | B462, A182 |

Mechanical Properties

Representative Tensile and Impact Properties, Plate

| Temp. °F (°C) | Ult. Tensile Strength, psi | .2% Yield Strength, psi | Elongation in 2”, percent | Charpy V-Notch Toughness, ft-lb |

| -450 (-268) | 218,000 | 142,000 | 36 | 353* |

| -320 (-196) | 196,000 | 107,000 | 49 | 85 |

| -200 (-129) | – | – | – | 100 |

| 70 (21) | 108,000 | 53,000 | 47 | 140 |

| 200 (93) | 99,900 | 49,400 | 47 | – |

| 400 (204) | 903,000 | 40,400 | 46 | – |

| 600 (316) | 86,000 | 36,300 | 47 | – |

| 800 (427) | 87,000 | 36,000 | 48 | – |