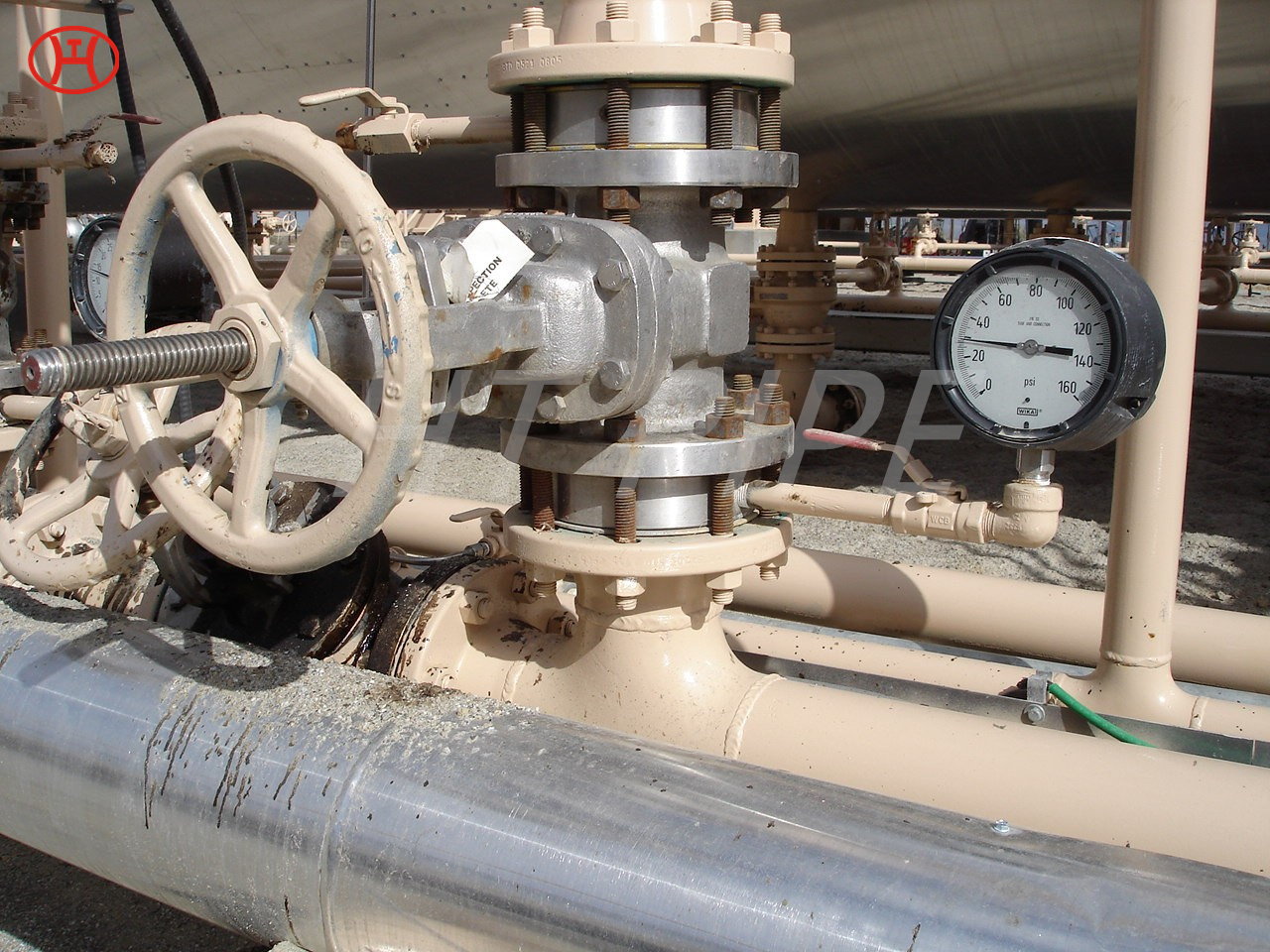

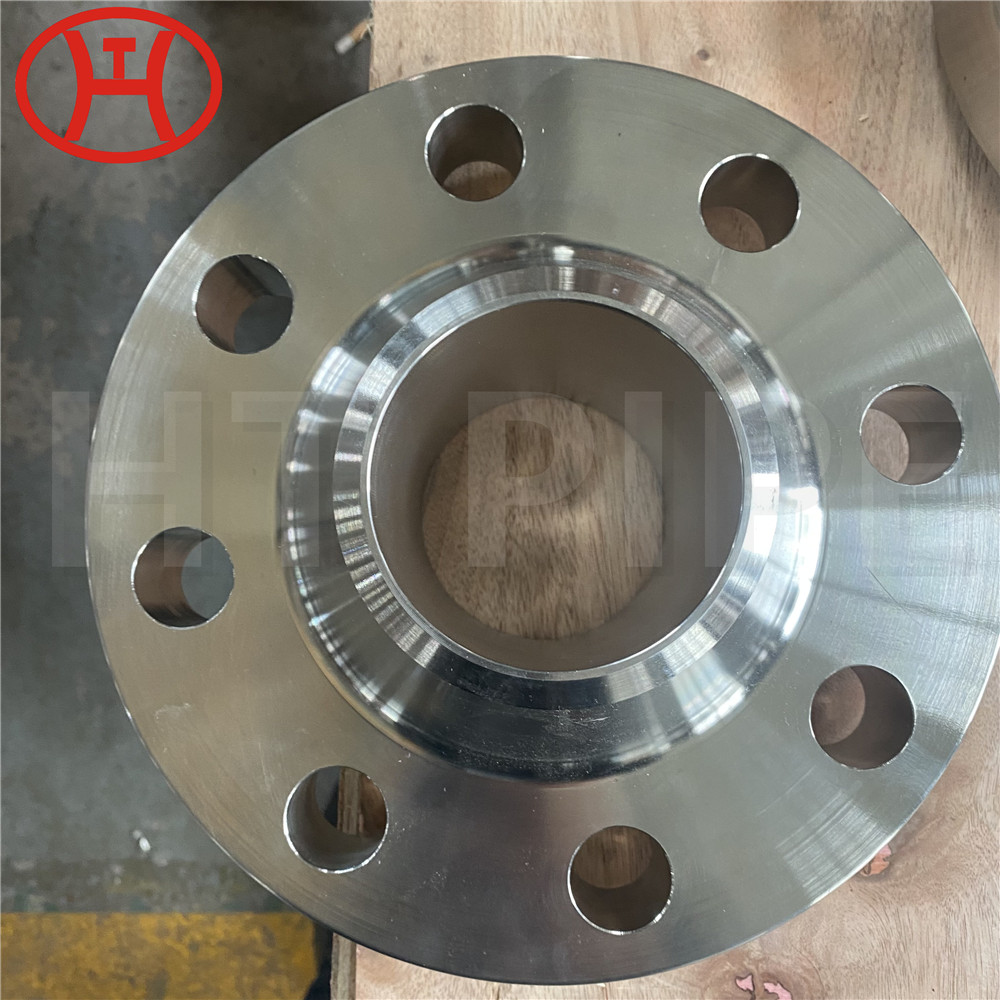

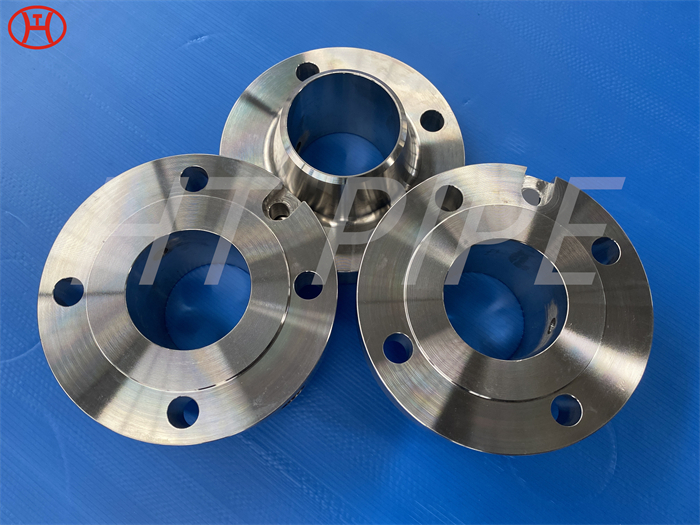

ANSI B16.5 SS 304L Pipe Flange ASME B16.48 304 Slip on Flange Stockist

ASME B16.47 Series A are available in Classes 150, 300, 400, 600, 900; that of ASME B16.47 Series B are available in Classes 75, 150, 300, 400, 600, 900

ASTM A182 F304L Slip On Flange Manufacturer And Supppliers In China, Buy SS 304L WNRF Flanges Online

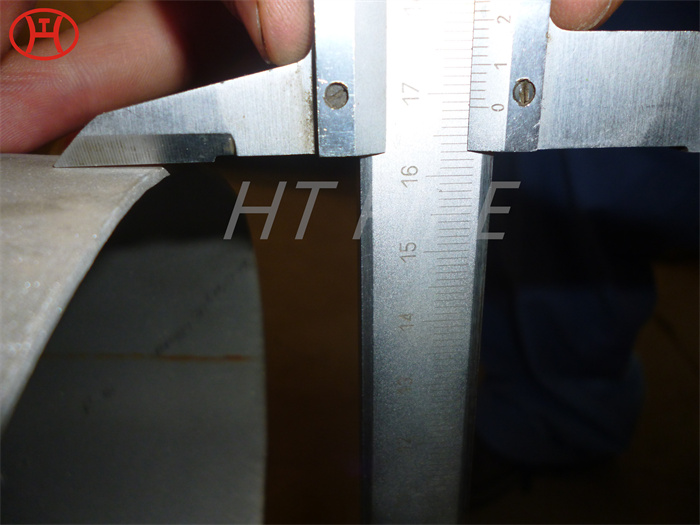

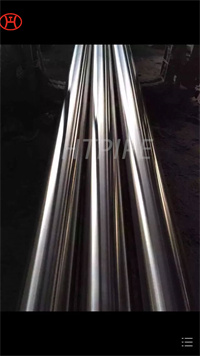

The low carbon chemistry of sa 182 f304l works in combination with the added nitrogen, enabling the alloy grade 304L to meet the mechanical properties of its predecessor 304. SA 182 F304l material chemically contains chromium and nickel in an 18-8 ratio. Stainless steel 304l flanges offer good resistance to atmospheric corrosion, as well as, both mildly oxidizing and reductive environments. The astm a182 f304l flange has excellent resistance to intergranular corrosion in an as-welded condition. Another important property of the werkstoff a182 f304l is its excellent strength and toughness. These two mechanical properties aid the A182 F304L Slip On Flanges in performing well even at cryogenic temperature environments. S30403 flange exhibits non-magnetic behaviour in the annealed condition, although the alloy can become slightly magnetic as a result of cold working or welding. sa 182 f304l material can be easily welded and processed by conventional shop fabrication techniques.

The high chromium content of the a182-f304l material provides the alloy with good resistance when exposed to oxidizing solutions such as nitric acid up to 55% of its weight as well as in high temperature conditions up to 176¡ãF . The 1.4301 flange is also known for its resistance tp moderately aggressive organic acids such as acetic acid. The nickel present in the alloy of 1.4301 304L flange provides resistance in moderately reductive solution containing environments. The resistance against reductive compounds or solutions include one such as pure phosphoric acid, in whatever concentration, or in cold solutions. Similarly, ASTM A182 F304L Flange can also resist up to 10% diluted hot phosphoric acid solutions. The Sa 182 gr f304l can also perform successfully in caustic solutions free of halogen containing compounds like chlorides or fluorides at moderate temperatures. Though A182 F304L flange does not perform well in a more highly reductive environment like those containing acids for e.g. – chlorides and sulfuric acid.

ASTM A182 SS 304 Flanges Mechanical Properties

| Grade | Tensile Strength | Yield Strength (0.2%Offset) | Melting Point | Density | Elongation |

| SS 304 | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 1400 °C (2550 °F) | 8.0 g/cm3 | 35% |

| SS 304L | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 1400 °C (2550 °F) | 8.0 g/cm3 | 35% |

| SS 304H | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 1400 °C (2550 °F) | 8.0 g/cm3 | 40% |