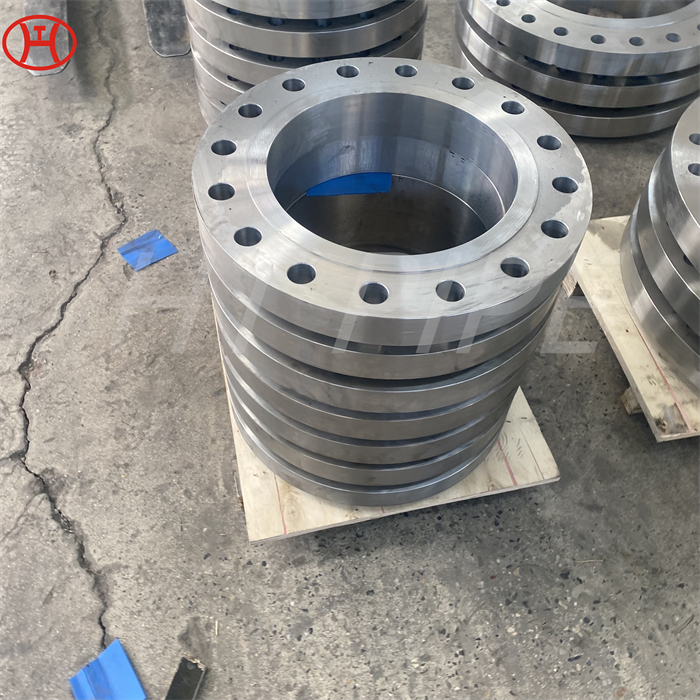

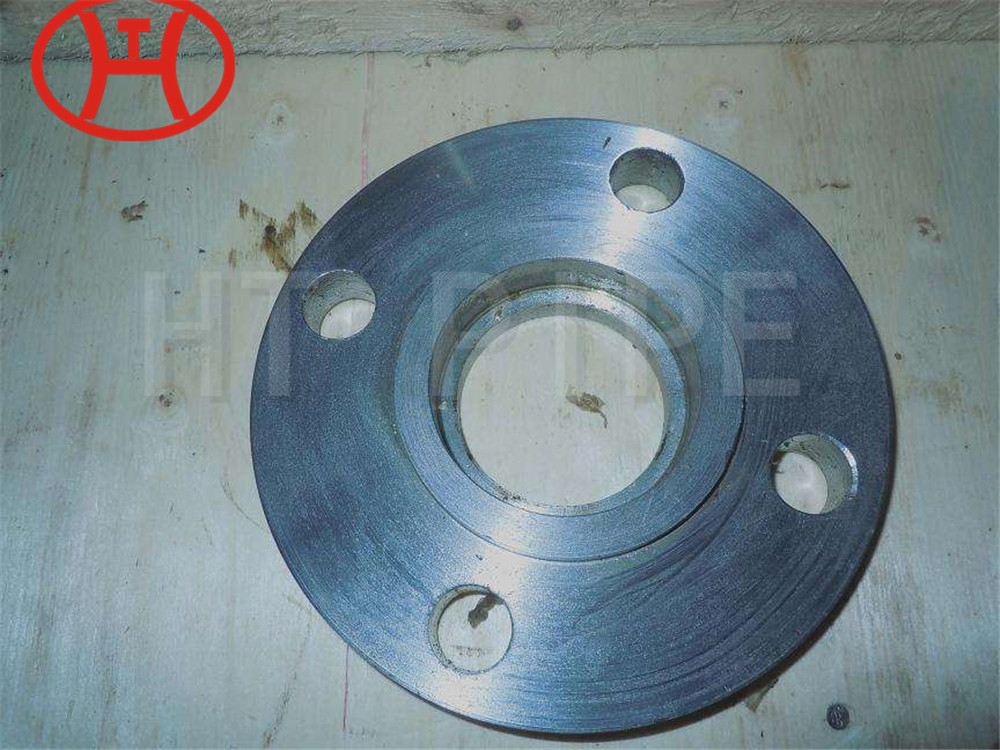

The exhibition of Zhengzhou Huitong forged flange 317l S31703 flange

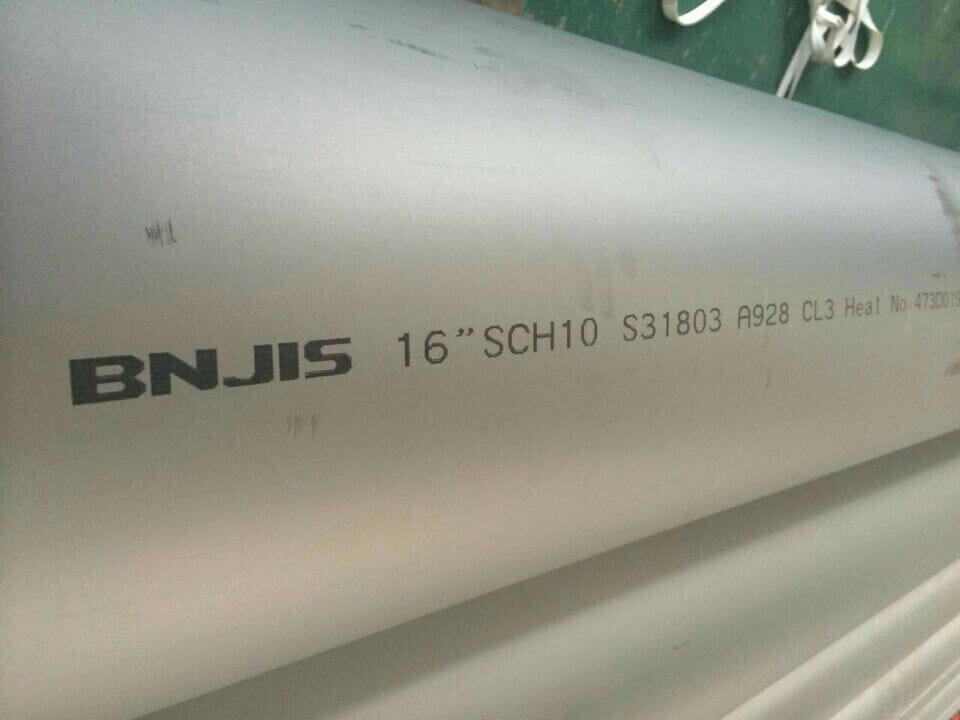

317/317L is a molybdenum containing austenitic steel with low carbon content. The increased content of chromium, nickel and molybdenum makes the grade more corrosion and chemical resistant. It has reliable robustness at high temperatures and offers an unmatched level of manufacturability. These properties of the SS317/317L facilitate its utilization in the aerospace and steel industries. In addition to this, our SS 317/317L flanges have excellent resistance to intergranular corrosion.

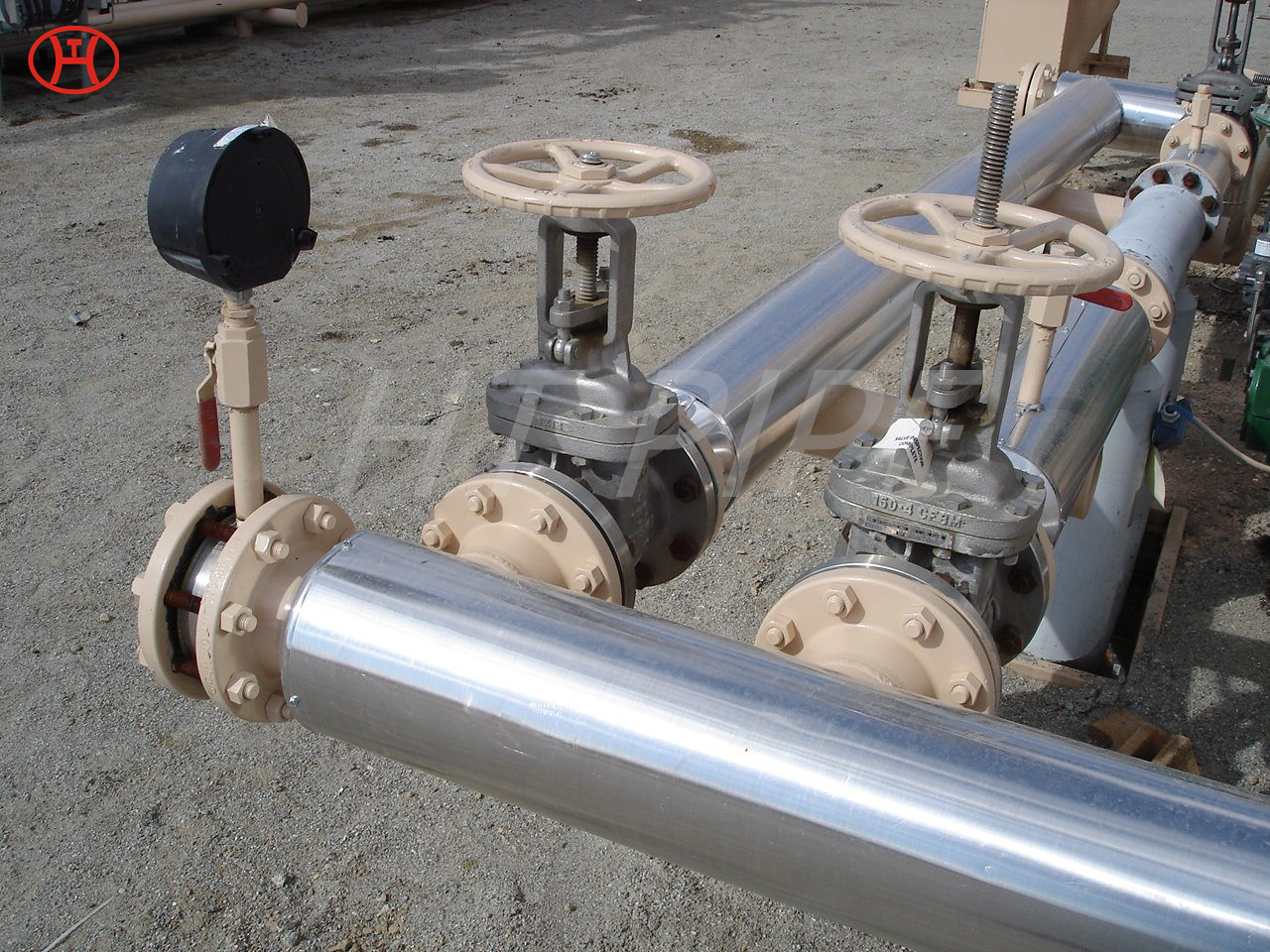

Stainless steel 317L flanges have excellent resistivity for acidic chloride environments. These flanges contain more chromium, nickel and molybdenum, which helps them have better resistance to chloride pitting and corrosion. Stainless steel 317 flanges and fittings are also resistant to sulfuric acid concentrations up to 5%. They maintain their resistivity at temperatures up to 120¡ãF (49¡ãC). We offer these stainless steel 317L threaded flanges in a variety of high quality materials primarily for boilers, heat exchangers, general service and food industry applications. Stainless Steel 317L Butt Weld Flanges specify the standard specification for nominal wall thickness welded pipe and cold worked welded pipe. At the same time, stainless steel 317L flanges and fittings are well suited to withstand higher concentration solutions at temperatures below 100¡ãF. Their high formability facilitates the manufacture of various flange faces suitable for different piping system requirements.