Stainless steel pipes and tubes of 254smo Z1 CNDU 20.18.06Az

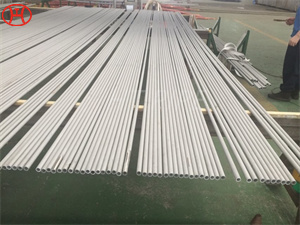

SMO 254 ERW piping is commonly used in seawater desalination, flue-gas cleaning, heat exchangers, etc. SMO 254 Welded Pipe is a very high end molybdenum and nitrogen alloyed super austenitic stainless steel with a low carbon content.

SMO 254 Stainless Steel Pipes, 6-Moly Pipes, 254 SMO Tubes, Alloy 254 Pipe Manufacturer, UNS S31254 Tubes Supplier, 1.4547 Pipe Exporter

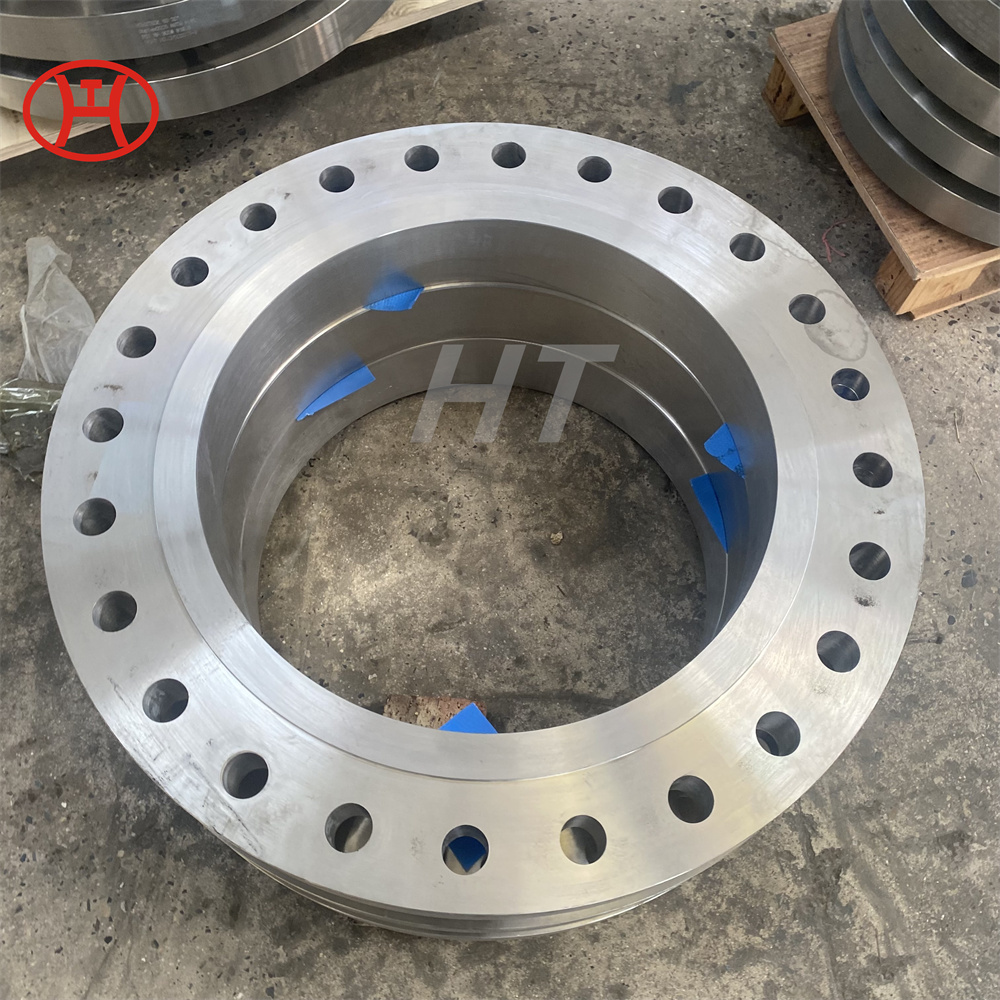

SMO 254 pipe will experience pitting and crevice corrosion in warm chloride environments and stress corrosion cracking above 60 degrees Celsius. Alloy SMO 254 pipe has excellent resistance to various atmospheric environments and many corrosive media. SMO 254 pipe is made of austenitic stainless steel product that is designed for the maximum resistant to crevice corrosion and pitting. 254 SMO Tube comes with high levels of molybdenum, chromium, nitrogen and is great for high chloride environments like bleach plants and chloride processing streams.

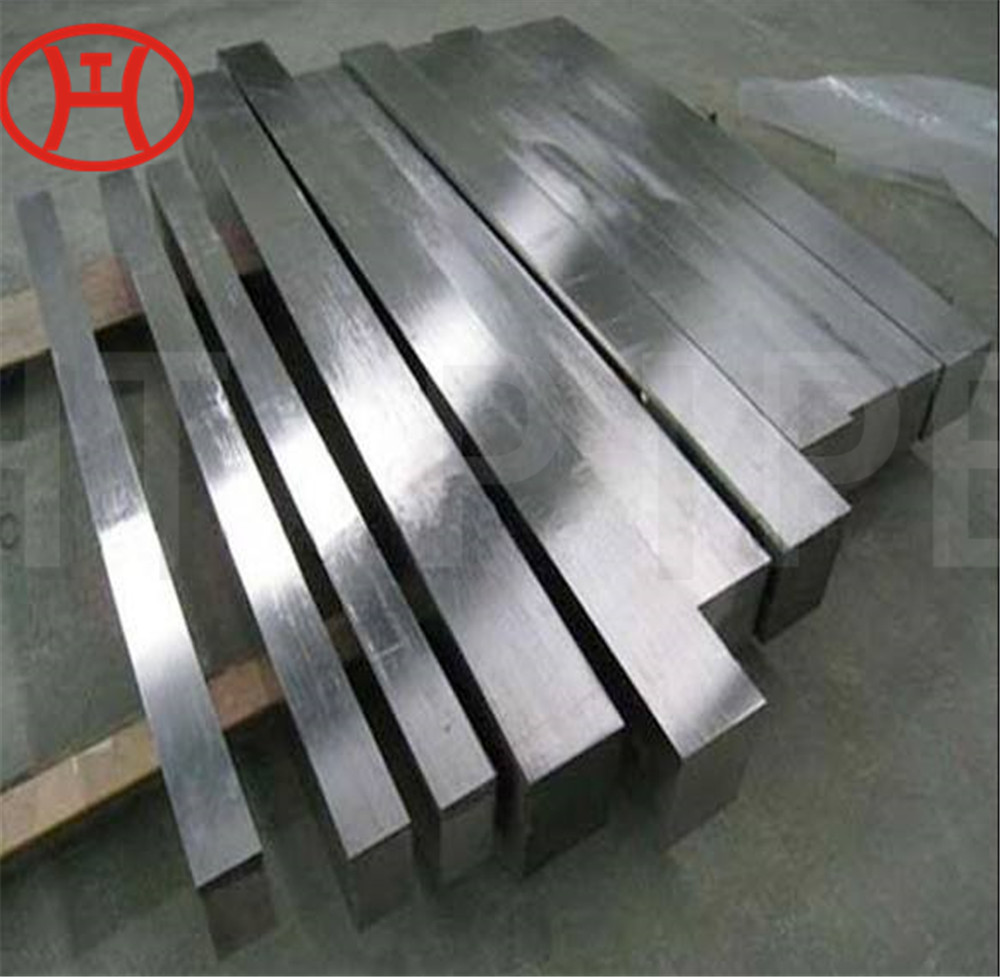

SMO 254 Stainless Steel Pipe has a very low carbon content. This means that there is very little risk of carbide precipitation during heating, for example when welding. The Alloy 254 Pipe passes the Strauss test (ASTM A262, practice E) even after sensitizing for one hour at 600–1000°C (1110–1830°F). However, due to the high alloying content of the steel, inter-metallic phases can precipitate at the grain boundaries in the temperature range 600–1000°C (1110–1830°F). These precipitations do not involve any risk of intergranular corrosion in the environments in which the UNS S31254 Tube is intended to be used. Thus, welding can be carried out without any risk of intergranular corrosion. Alloy 254 SMO is an austenitic stainless steel alloy with 6% molybdenum and nitrogen. 1.4547 Pipe has a very high resistance to crevice and surface corrosion. Alloy 254 SMO was specially developed for the pulp and paper industry and for offshore use on oil and gas platforms. We manufacture and export and distribute and are UNS S31254 1.4547 Pipe supplier. The 6-Moly Pipes are manufactured in the various material specification and dimension standards based on the application and requirement. Readily applied in a range of industries, the products are well accepted and liked by various kinds of industries all over the world.

| C | Si | Mn | P | S |

| ≤ % | % | ≤ % | ≤ % | ≤ % |

| 0.02 | 0.70 | 1.0 | 0.03 | 0.01 |

| Mo | Ni | N | Cu | Cr |

| % | % | % | % | % |

| 6.0 – 7.0 | 17.5 – 18.5 | 0.18 – 0.25 | 0.5 – 1.0 | 19.5 – 20.5 |