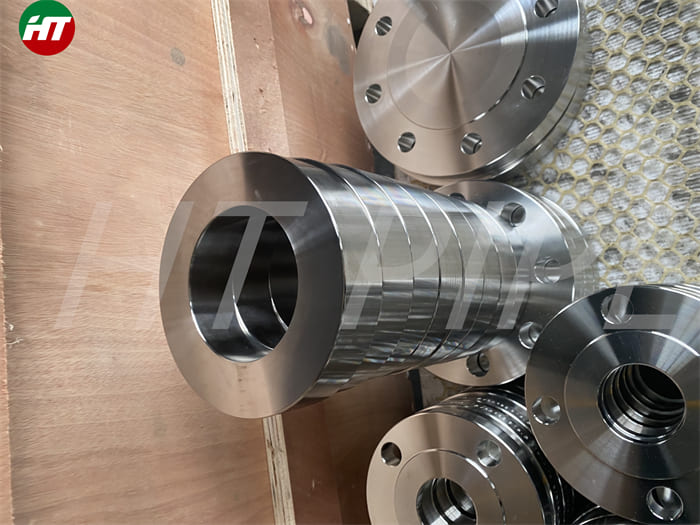

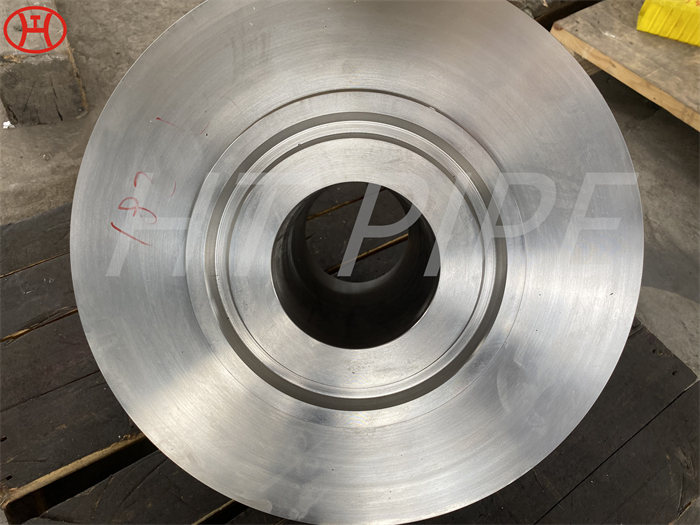

Hastelloy X N06002pipes with nickel alloy reducers

Alloy X is known for its excellent high temperature strength and can withstand temperatures up to 2200¡ãF. The alloy can also be easily fabricated by manual and automated methods with forming and welding properties. In addition, Hastelloy X is resistant to corrosion, heat and oxidation and can withstand reducing or neutral atmospheres and oxidation.

Hastelloy X is a nickel-chromium-iron-molybdenum alloy with the perfect blend of oxidation resistance, ease of workability and high temperature strength. It also exhibits excellent resistance to stress corrosion cracking in petrochemical applications.

Superalloys or high performance alloys come in many shapes and contain elements in different combinations to achieve specific results. These alloys are divided into three types, including iron-based, cobalt-based and nickel-based alloys. Depending on composition and application, nickel- and cobalt-based superalloys are available as cast or wrought alloys.