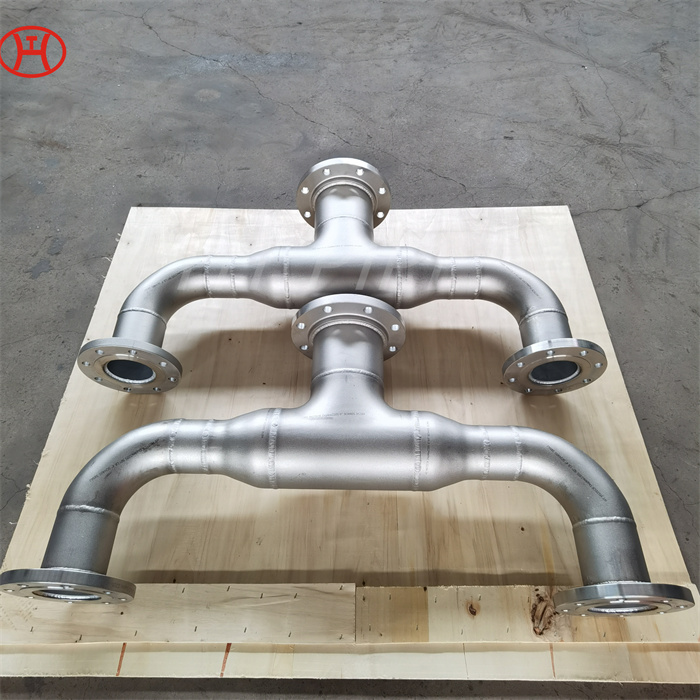

MSS SP-44 Hastelloy B3 Socket Weld Flange

Hastelloy B3 Blind Flanges have good creep, and oxidation¡¯s resistance. Hastelloy B3 Weld Neck Flanges isn¡¯t recommended for use in the presence of ferric or cupric mariners because these mariners can bring unseasonable failure.

Due to this feature, Hastelloy B3 Flanges are widely suitable for industries that include chemical processing and soar acid. These flanges have excellent weldability and formability properties using the standard methods. The The flanges are forged using die cast method that uses specific load of weight to shape the cast alloy into the flanges. The flanges come in welded as well as threaded types making it easy for the user to chose from dual options. B3 grade flanges are widely used in the chemical industry due to their resistance to stronger acids such as sulfurs and phosphors without any change in its physical properties. The Nickel Alloy C276 Slip On Flange is widely used in the industry due to its low price and easy installation process. These flanges can be easily slid on piping devices and welded using one or more fillet welds. Hastelloy Blind Flange is used to terminate or close the end of high-pressure and temperature fluids and gases in the system. The versatile DIN 2.4819 Flanges are produced with the best raw materials and latest technology under the watchful eye of esteemed staff. If you have any queries or want to know more about this range of products and it¡¯s pricing, visit us or contact us for more information.