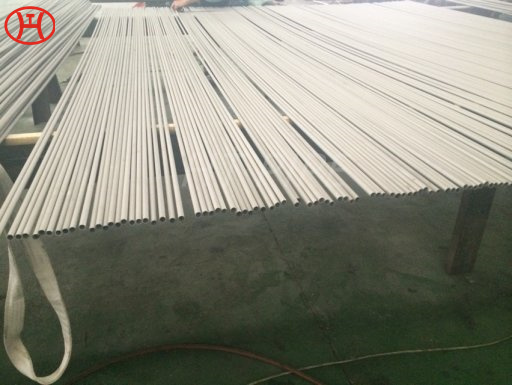

Stainless steel pipes of 254smo 1.4547 Smo 254 Pipe Manufacturers

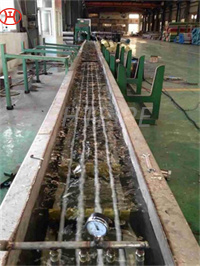

Alloy 254 SMO contains high levels of chromium, molybdenum and nitrogen and is often used in high chloride environments such as brackish water, sea water, pulp mill bleach plants and other chloride process streams.

ASTM A312 UNS S31254 Stainless Steel Seamless Pipe Manufacturer and suppliers in China, 254 SMO Seamless Pipe Suppliers, Alloy 254 Seamless Pipe Stockist, UNS S31254 Seamless Pipe Dealer

ASTM A312 UNS S31254 pipe without a seam or weld is known as Seamless Pipe. SMO 254 Pipes can withstand high mechanical stress and high pressure can work in high temperatures and corrosive environments. Stainless Steel Seamless Pipe is formed by drawing a solid metal billet over a piercing rod to create a hollow tube. SMO 254 Seamless Pipe is then processed and finished as per dimension standard ASTM A312 UNS S31254, ANSI B36.10 and ANSI B36.19 and B36.19M in different wall thickness and sizes ranging from SCH 5S to SCH XXS. 6Mo Seamless Pipes have varied applications in the Oil and gas, Chemical, Pharmaceutical, Fertilizer, Agro-Chemical, Aerospace, Desalination, Food and Beverage, Sugar, Distillery, Power Generation, Cement, Petroleum Refinery, mechanical and structural, food processing, etc.

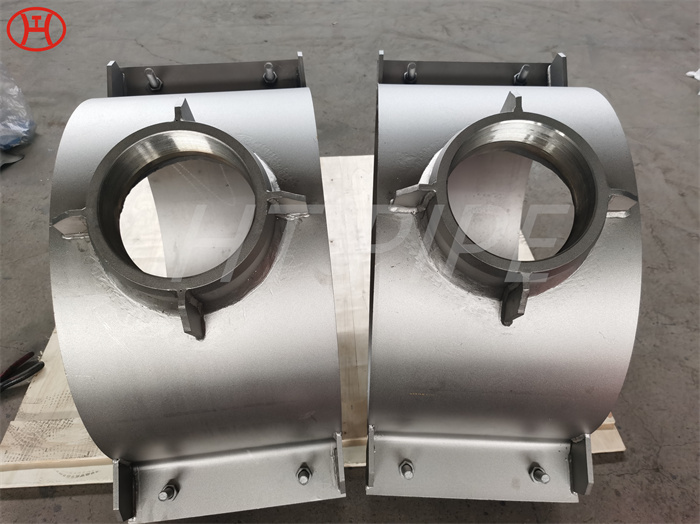

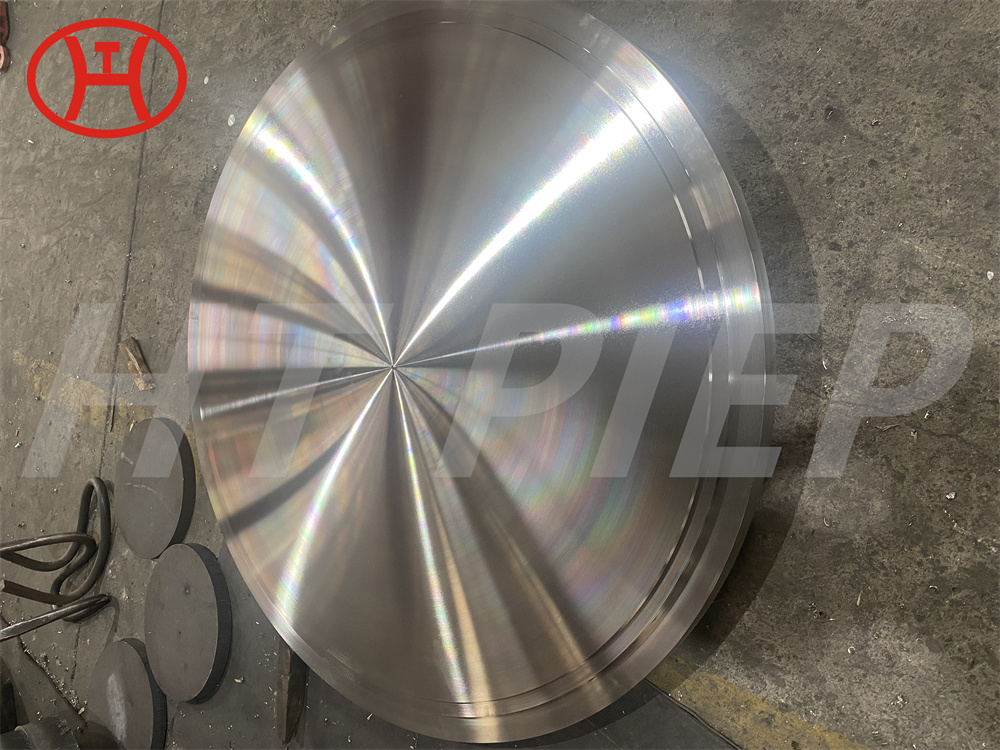

High levels of alloying elements give SMO 254 Pipe excellent resistance to uniform corrosion. Due to its high alloy content of chromium and molybdenum, DIN 1.4547 pipe can withstand a wide range of acids. Resistance to pitting and crevice corrosion mainly depends on the content of chromium, molybdenum and nitrogen. Its design combines impact toughness against chloride stress corrosion cracking, pitting and crevice corrosion. A flat strip or sheet or plate of 254 SMO alloy is pressurized into desired cylindrical hollow pipe spread across the longitudinal stretch. This pipe is then pressed again for the either ends of sheet to meet and welded together using high energy welding source like an electric arc, laser beam, plasma arc, electron beam etc. Then is 254 SMO Round Pipe allowed to cool and solidify, thereby forming a 254 SMO Welding Pipe. This 6Mo Welded Pipes contains weld or seam or joint, and hence are cheaper than its counterpart Seamless Pipes and hence more in demand and readily available. The wall thickness of 6Moly Welded Pipes is more consistent than its counterpart. Inner surface of UNS S31254 Welded Pipes can be checked and cleaned before manufacturing then, which is not possible in seamless pipes.

Specifications – Stainless Steel 254SMO

Chemical Composition – Stainless Steel 254SMO

| C | CR | CU | MN | MO | N | NI | P | S | SI |

| Max | Max | Max | Max | Max | |||||

| 0.02% | 19.5% – 20.5% | 0.5% – 1.0% | 1.00% | 6.0% – 6.5% | 0.18% – 0.22% | 17.5% – 18.5% | 0.03% | 0.01% | 0.80% |