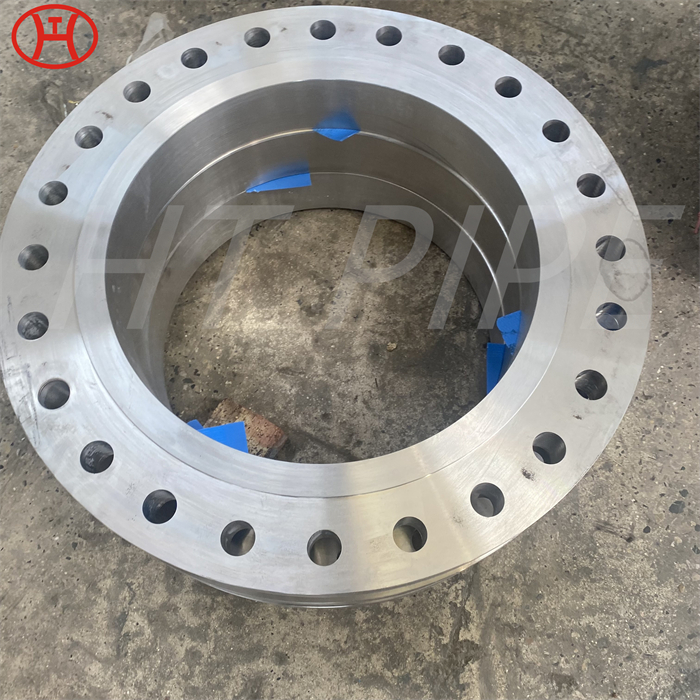

Incoloy 925 Stainless Steel Flange Nickel Iron Chromium Alloy Flange

Incoloy 925 flanges are made of a precipitation hardened nickel alloy. It offers comparable corrosion resistance to it¡¯s sister alloy Incoloy 825, but with the increased strength resulting from the age hardening process.

Incoloy 925 Lap Joint Flanges has a high level of corrosion resistance and resists general corrosion, pitting, crevice, inter – granular corrosion and stress corrosion cracking. HT PIPE has given an impetus to various industries through the last three decades, with its outstanding products and exceptional services. Incoloy 925 Ring Type Joint Flanges is produced by a vacuum re-melt process, but can be supplied using an air melt single consumable electrode (VAR or ESR) practice if the material specification allows. The combination of the nickel and chromium gives it the protection in both oxidizing and reducing environment. These flanges also show resistant to chloride. They are made hardened by mixing aluminium and titanium and which give it strength during high heat treatment. It has the property to sustain its shape at high temperatures. These flanges are also resistant to inter-granular corrosion.