ASME B16.9 Butt Welding Stainless Steel Fittings Cap

In order to convey the pipeline, it is necessary to remove the straight hose in the pipeline. When using various pipelines, various pipelines must be used. When the pipeline is used, the elbow must be used to change the size of the pipeline. When bifurcating, the three-way pipe The flange connection used when the joint is used with various pipe joints, in order to reach the long-distance transmission pipeline, in order to reach the thermal expansion and cold contraction joint or effective connection aging of the pipeline, the long-distance expansion and cold contraction joint is used for the connection of the pipeline. , In the connection of various instruments, there are also the connectors and plugs of the instrument phase.

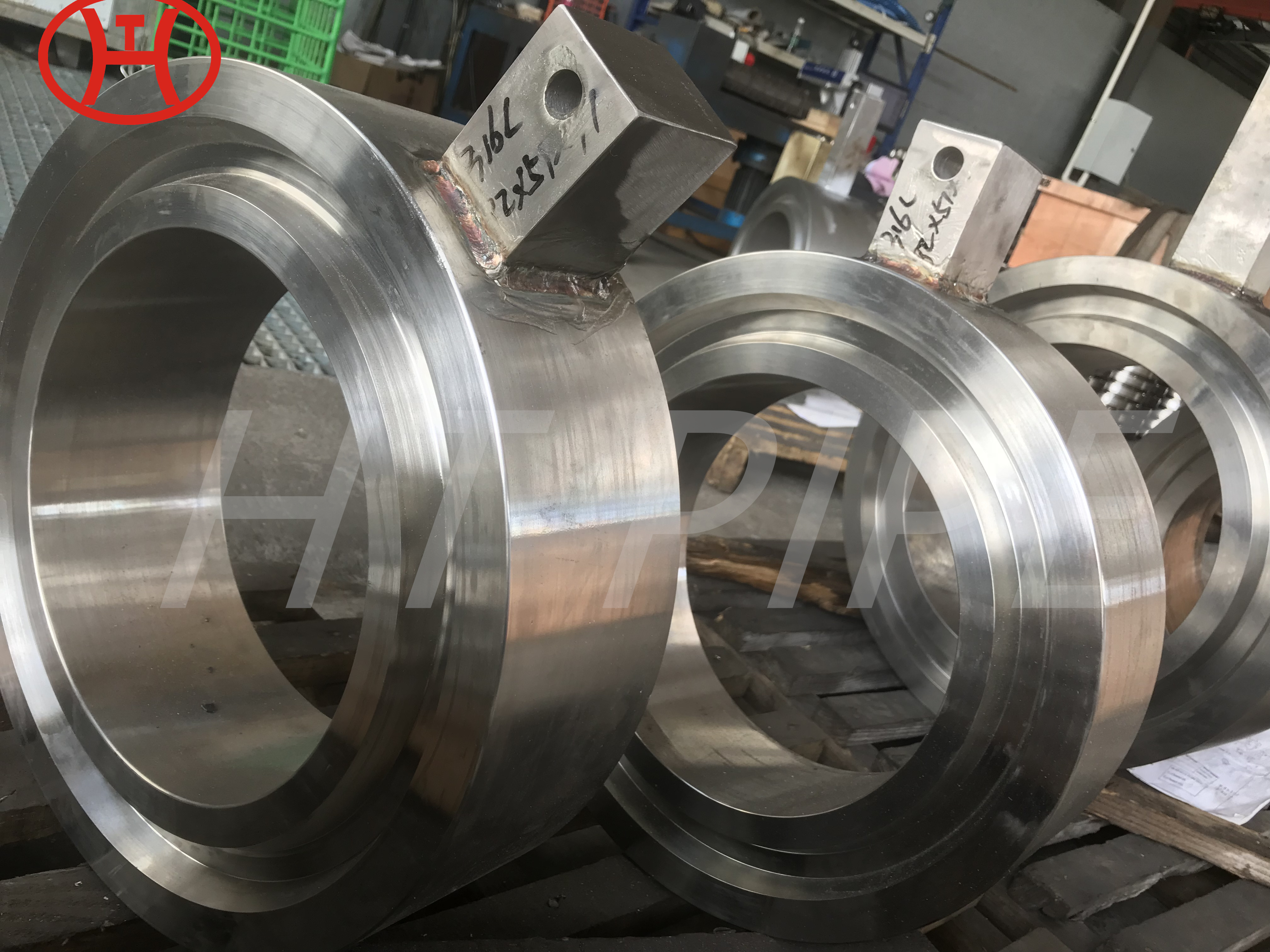

A stainless steel butt weld cap is a type of pipe fitting that covers the end of a pipe. Since it can have female threads, it can screw on to the male end of the pipe. It can also be welded on to close the end of the pipe. On a weld, if it is a temporary close, or the contractor wants to add to the piping system in the future, he or she should allow additional pipe before closing so the pipe cap can be cut off and the pipe system extended as needed. This way you will not have less pipe than you need and the new fitting can be attached correctly.

A Stainless Steel Butt Weld Cap is used to seal the end of a pipe or a particular butt weld fitting branch or orifice. Typically butt weld pipe caps are used at the end of a piping system or if maintenance is required the pipe cap can blind or isolate the rest of the system to keep it running while maintenance or repairs are performed.