ASTM ASME SB 574 Hastelloy C276 bright steel round bar UNS N10276 Nickel alloy bar

Hastelloy UNS N10276 cold drawn bar has excellent resistance in a variety of chemical process environments. For example, Hastelloy C276 UNS N10276 square bar is resistant to corrosion in a variety of media, including strong oxidants (such as ferric chloride and cupric chloride), hot fouling media (may be organic or inorganic), chlorine, acetic anhydride , formic acid and acetic acid, as well as good tolerance to seawater and saline solutions.

Hastelloy C276 Round Bar Stockist, UNS 10276 / WNR 2.4819 Rod, Hastelloy c276 round bar suppliers, Manufacturers of UNS N10276 Hastelloy C276 Hex Bar in China, Suppliers of Alloy C276 Bar

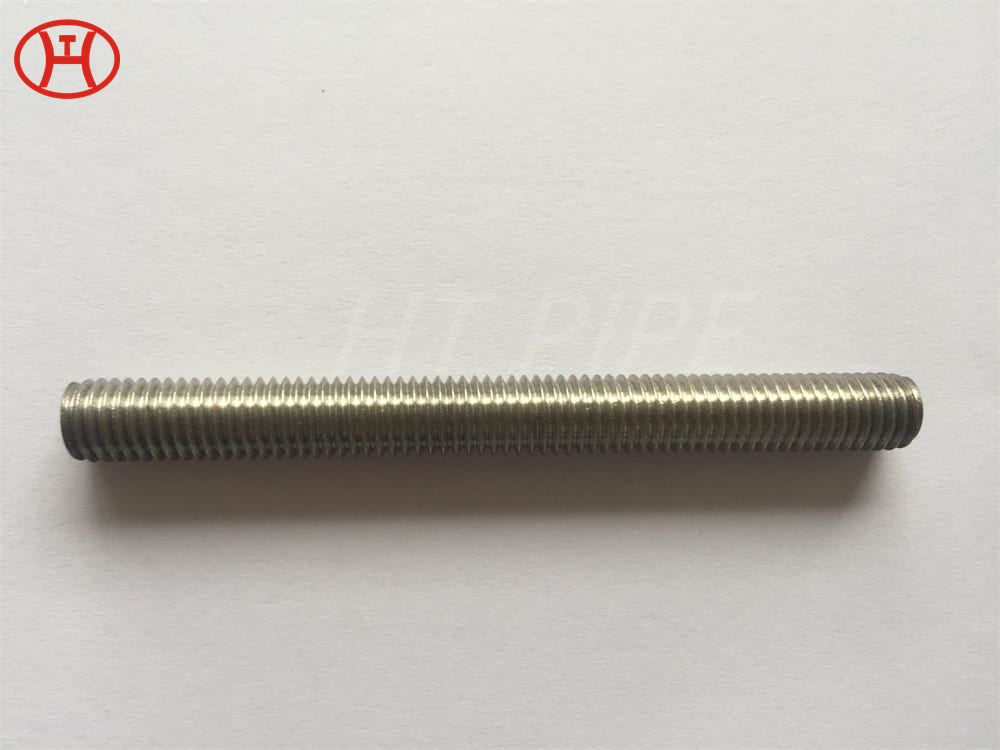

HASTELLOY C276 Round Bar is a Nickel Chromium and Molybdenum wrought alloy that is considered the most versatile corrosion resistant alloy available. UNS N10276 Round Bar is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making WNR 2.4819 Rod suitable for most chemical process applications in an as welded condition. Hastelloy c276 round bar also has excellent resistance to pitting, stress-corrosion cracking and oxidizing atmospheres up to 1900°F. Hastelloy C-276 has exceptional resistance to a wide variety of chemical environments. UNS N10276 Hastelloy C276 Hex Bar exhibits excellent corrosion resistance in a variety of harsh environments and media.

The base constituent of Hastelloy C276 Round Bar alloy is chemically composed of three elements, which are nickel, molybdenum and chromium. This wrought Haynes Alloy C276 Cold Finished Bar is generally considered to be a versatile, yet corrosion resistant alloy. Because of its excellent resistance to sulfur containing compounds and chloride ions encountered in most scrubbers, the Hastelloy C276 Grade Round Rod can be used in flue gas desulfurization systems. Alloy C276 Hastelloy Bar Stock also has excellent resistance to localized corrosion like pitting and the alloy is able to resist stress related corrosion cracking. The Hastelloy C276 N10276 Bright Bar is also one of the few materials which could withstand the corrosive effects of chlorine in the following forms i.e. – wet chlorine gas, hypochlorite, and chlorine dioxide.

| Grade | ASTM B574 UNS N10276 , ASTM B574, ASME SB574 Bar Products, NACE MR-01-75, Inconel C276 (trademark) |

| Specification | AMS 5750 (Hastelloy C, UNS N10002) |

| ASTM B751 | |

| Werkstoff Nr. 2.4819 | |

| DIN 17744, DIN 17750, DIN 17751 and DIN 17752,VRC276 | |

| Standard | ASTM, ASME, API, GB, AISI, DIN, EN, SUS, UNS |

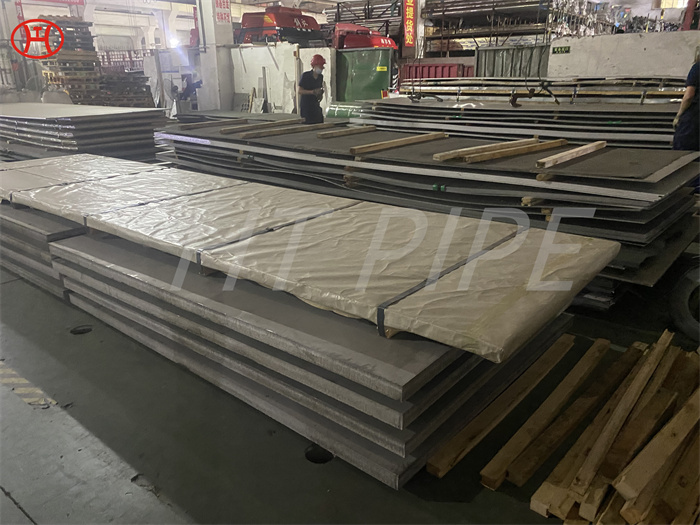

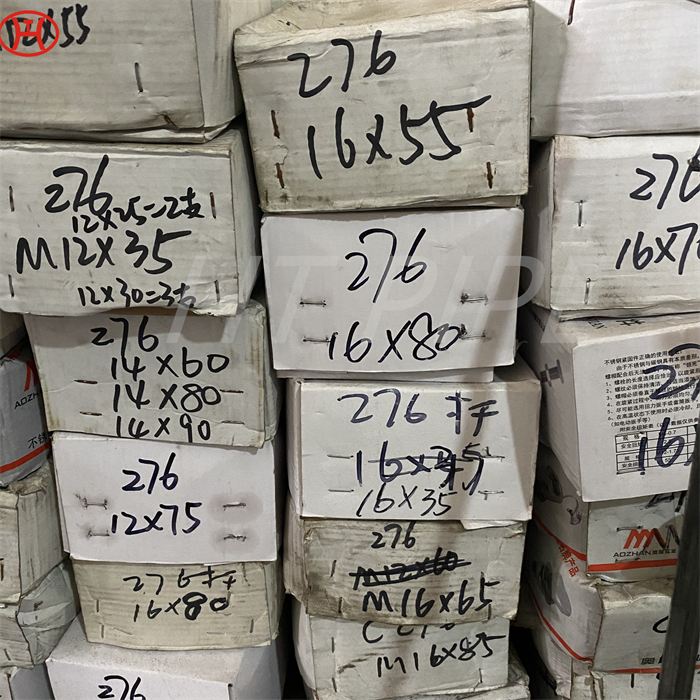

| Alloy C276 Round bar size | Diameter: 3-~800mm |

| C276 Hastelloy Hex Bar size | 2-100mm A/F |

| Hastelloy Alloy C276 Flat bar size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| C276 Hastelloy Alloy Square bar size | 4 to 100mm |

| Hastelloy C276 Angle bar size (in mm) | 3*20*20~12*100*100 |

| ASTM B574 Hastelloy C276 Section | 3.0 to 12.0mm thickness |

| Hastelloy WERKSTOFF NR. 2.4819 Channel Bar (in mm) | 80 x 40 to 150 x 75 section; 5.0 to 6.0 thickness |

| Nickel Alloy C276 Hollow Bar (in mm) | 32 OD x 16 ID to 250 OD x 200 ID) |

| 2.4819 Hastelloy C276 Billet Size | 1/2″ to 495mm Diameter |

| ASTM B574 C276 Hastelloy Rectangles Size | 33 x 30mm to 295 x 1066mm |

| C276 Hastelloy Round Bar Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Alloy Hastelloy C276 Round Bar Surface | Bright, Hot Rolled Pickled, Cold Drawn, Sand Blasting Finished, Polished, Hairline |

| Hastelloy C276 round bar Condition | Hardened & tempered, annealed |

| C276 Hastelloy Bar Technique | Hot Rolled, Cold Drawn, Cold Rolled, Forged Round Bar, Rod |

| Hastelloy C276 Din 2.4819 Round Bar Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| UNS N10276 Hastelloy Bar Processing | Bar cutting to 650mm |

| Our Hastelloy C276 round bar stockyad in India | Mumbai, Agra, Shivamogga, Gujarat, Bhubaneswar, Thiruvananthapuram, Noida, Coimbatore, Bengaluru, Ahmedabad, Pune, Chennai, Tiruchirappalli,Dhanbad, Hyderabad, Tirunelveli, Navi Mumbai, Pimpri-Chinchwad |

| Our Hastelloy Alloy C276 Round bar conforms to NACE MR0175/ISO 15156 | |