ASME SB 622 UNS N10276 Redrawn Tube and Alloy C276 Seamless Tubing supplier

Available in various forms, the material is known to be very versatile. The basic chemical makeup of a Hastelloy C276 seamless Pipe includes Nickel, chromium, and molybdenum in its alloy. The trio elements in this wrought alloy are what gives the Hastelloy C276 welded Pipe its high mechanical properties in addition to its excellent corrosion resistance properties.

Manufacturer and exporter of Hastelloy C276 Annealed Tubes & DIN in China

ASTM B619 UNS N10276 Alloy C276 Tube covers 2 classes under this specification. In class 1, the Hastelloy C276 Tube is furnished in an as welded and solution annealed condition or these tubes could be welded along with being sized and solution annealed. On the other hand, the class 2 Hastelloy C276 Welded Tubing produced according to the ASTM B619 specification is welded, cold worked and is furnished in a solution annealed condition.

The content of nickel in its alloy amounts to about 57%. The high content of nickel in an alloy, including Alloy C276 Pipe, indicates that UNS N10276 Alloy C276 Tube has the ability to withstand elevated temperatures. The solution strengthened material also has a lower content of carbon in the alloy of ASTM B619 Hastelloy C276 Welded Pipe. Therefore, the weldability of this alloy is considered to be good. Generally, alloys that are welded are prone to get corroded on the grain boundary precipitates. However, because the ASTM B622 Hastelloy C276 Pipe has a high content of nickel and low content of carbon in its alloy, the material is resistant to the development of grain boundary precipitates in the HAZ or heat-affected zone, during welding. Therefore, the material is regarded as a commercially viable solution for several chemical process applications, where Hastelloy DIN 2.4819 Sanitary Tube could be used in an as welded condition.

While each specimen or in this case ASTM B622 UNS N10276 Alloy N10276 Tube produced in accordance with the ASTM B622 specification is to adhere to mechanical properties such as tensile strength, yield strength, and elongation. Moreover, the ASTM B622 specified 2.4819 Alloy C276 Tube is to undergo several tests such as tension test, hydrostatic test as well as non-destructive electric test. The mass or weight of each Hastelloy C276 Seamless Tube is required to be calculated. And the chemical composition of each ASTM B622 UNS N10276 Tube needs to be determined. Similar to most nickel based alloys, the Hastelloy C276 Tubing has good resistance in oxidising and reducing environments.

Stockist and supplier of UNS N10276 exhaust tubing according to ASTM B622, ASTM B775, ASTM B619, ASTM B626, ASTM B516 standards

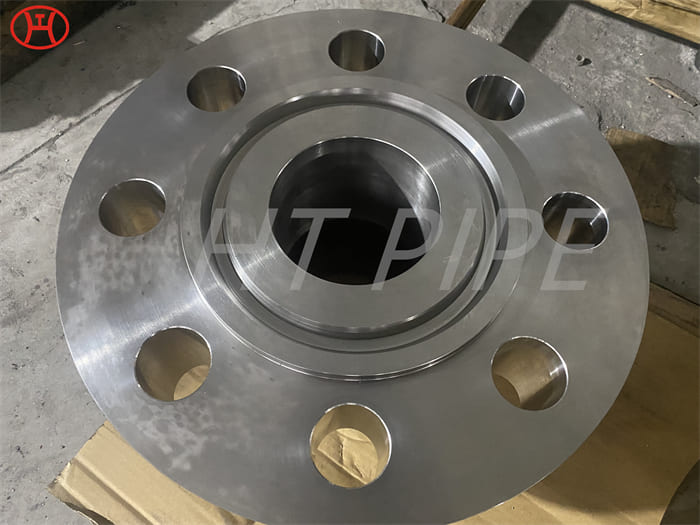

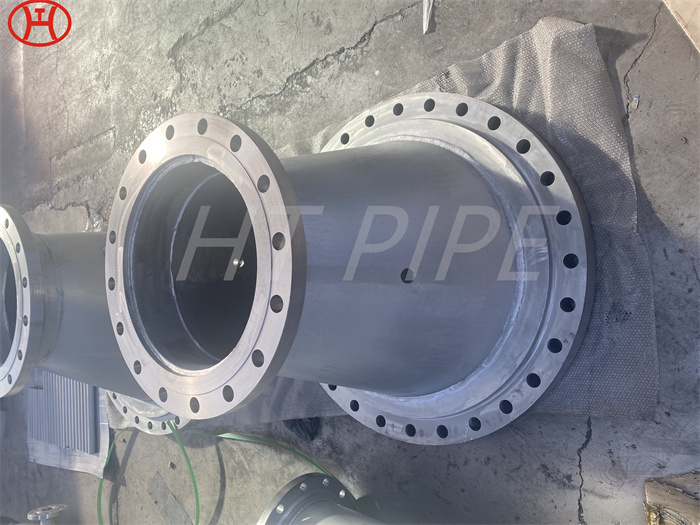

| ASTM/ ASME Specification | ASTM B619/ ASME SB 619, ASTM B622 / ASME SB 622 Standard tubing supplier Specification for Hastelloy C276 Seamless & Welded Superheater, Condenser, Hydraulic, Boiler and Heat-Exchanger Tubes |

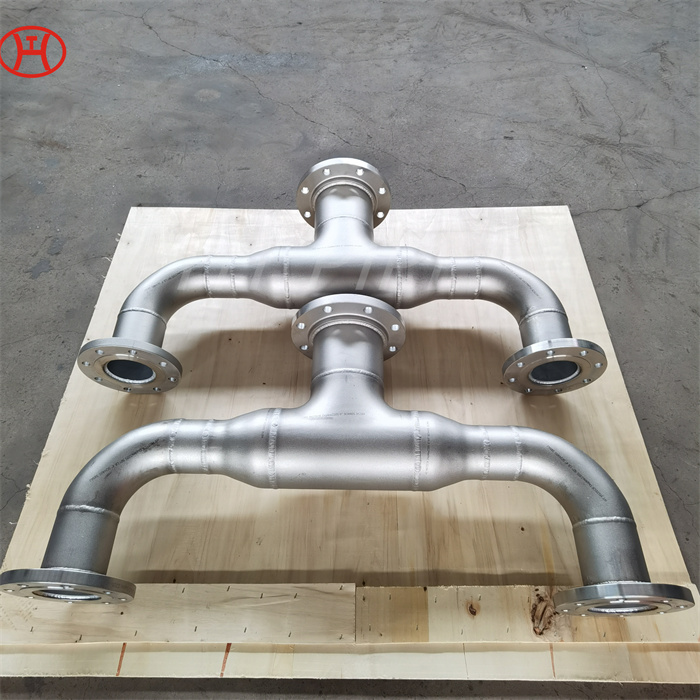

| Shapes | ASTM B622 UNS N10276 Round, Rectangular, Square, Hydraulic, Straight, “U” Shape, Coiled, Honed Tubes, Pan Cake Coils |

| Manufacturing Type | Seamless / ERW / Welded / Fabricated / CDW / CDS / DOM / CEW / 100% X Ray Welded |

| Thickness Range | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXH, SCH XXS, SCH XS |

| Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Standard | SUS, JIS, AISI, ASTM, GB, DIN, EN |

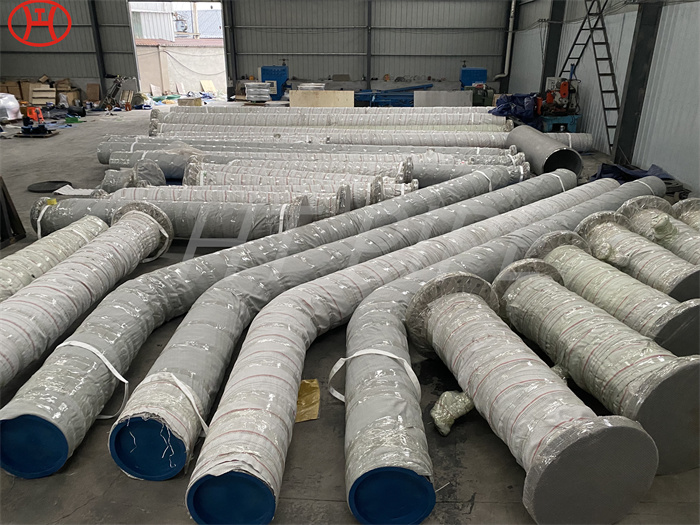

| Delivery Condition | Annealed and Pickled (AP), Polished, Bright Annealed (BA), Cold Drawn, MF |

| Value Added Services |

|

| END | Plain End, Beveled End, Treaded ASME SB 622 UNS N10276 Tube manufacturer |

| Processing Service | Bending, Welding, Decoiling, Punching, Cutting, Moulding |

| Technique | Hastelloy Alloy C276 Cold drawn, Cold rolled, Hot rolled, Extrusion Tube |

| Marking |

Marked Sample: ASTM B622 UNS N10276 Seamless 113.60 mm OD x 6 mm W.T. HEAT No. xxxxxx |

| Test Certificate |

|

| C276 Tubing Packaging | Packed in PE Fabric Bundles or ply wooden box wrapped in plastic or Standard seaworthy export packing or as per customers’ request |

| Port | Mumbai, India |

| Stocking distributor of |

|