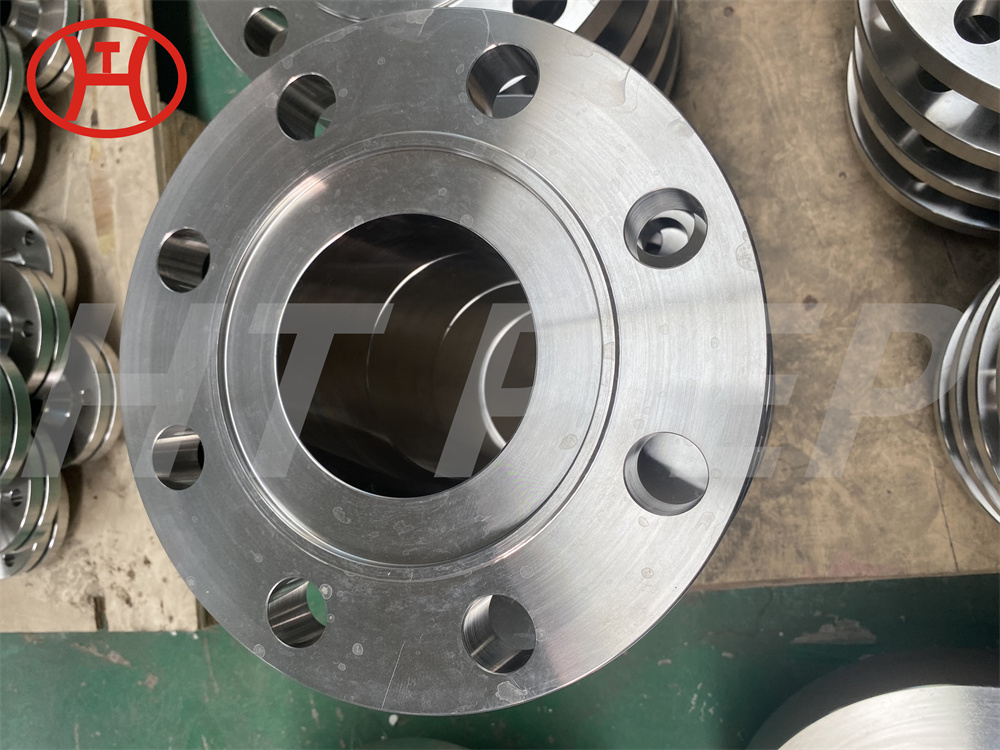

normalizing of 316L S31603 Z3CND18-14-03 stainless steel flange

It is important that the material used for any project has the correct mechanical properties for the specific application. Heat treatment processes are often used to alter the mechanical properties of metals, and one of the more common heat treatment processes is normalizing.

Normalizing is very similar to annealing in that both involve heating a metal to or above its recrystallization temperature and allowing it to cool slowly to produce a relatively ductile microstructure. The key difference between annealing and normalizing is that annealing allows the material to cool at a controlled rate in a furnace. Normalizing can be cooled by placing the material in a room temperature environment and exposing it to air in that environment.

This difference means that normalizing has a faster cooling rate than annealing. Faster cooling rates result in slightly less ductile and slightly higher hardness values ??than if the material had been annealed. Normalizing is also generally less expensive than annealing because it does not require additional furnace time during cooling.