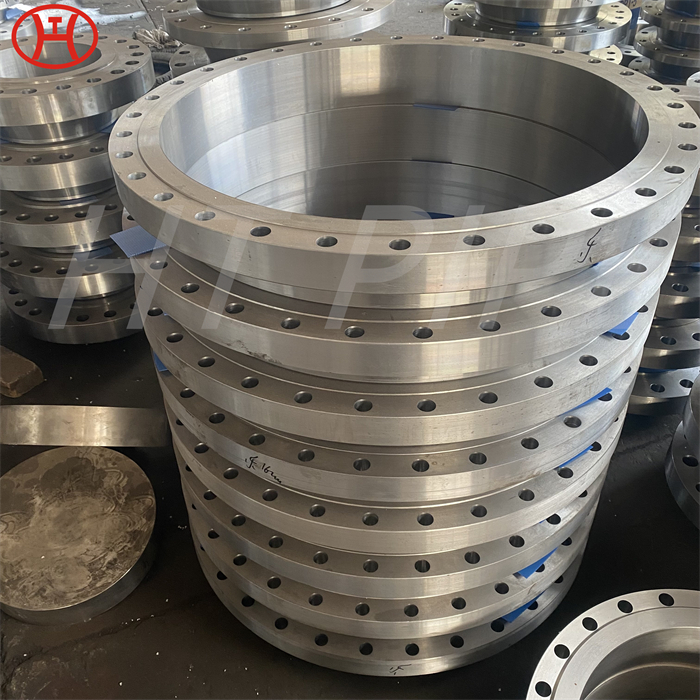

Stainless steel 347 Blind flanges 6inch 300lbs in stock

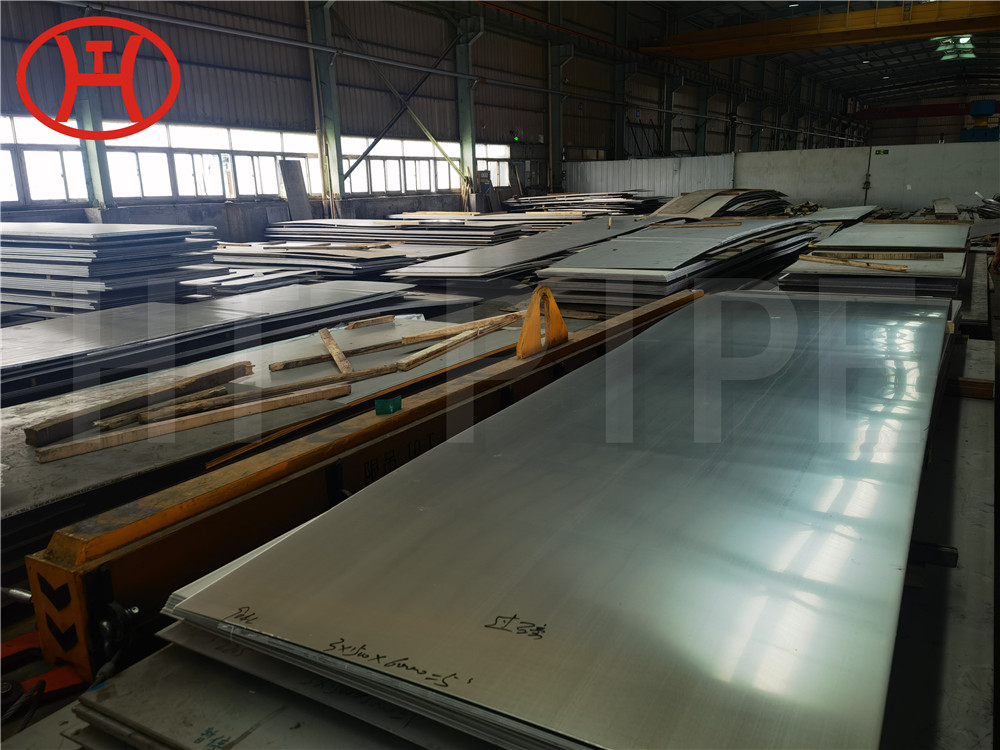

stainless steel flange is a kind of general steel material, which is widely used to manufacture equipment and parts with high requirements for comprehensive performance (corrosion resistance, formability). stainless steel is a stainless steel grade produced according to American ASTM standards. stainless steel is the most widely used stainless steel and heat-resistant steel. It is applicable to food production equipment, Xitong chemical equipment, nuclear energy, etc.

Stainless steel flange is also called stainless steel flange or flange. It’s a part that connects pipes to pipes. Connect to the end of the pipe. There are holes in the stainless steel flange, and bolts can be pierced to make the two stainless steel flanges close together. Stainless steel flanges are sealed with gaskets. Stainless steel flange is a kind of disc-shaped parts, which is most common in pipeline engineering. Flanges are used in pairs. In pipeline engineering, flange is mainly used for pipeline connection. In the pipeline that needs to be connected, a flange can be installed in all kinds. The low pressure pipeline can use the wire flange, and the welding flange can be used under pressure of more than 4 kilograms.

The corrosion resistance of stainless steel flange depends on chromium, but because chromium is one of the components of steel, the protection methods are different. The atmospheric corrosion resistance of steel increases significantly when the chromium content reaches 11.7%, but it is not obvious when the chromium content is higher.