321 stainless steel pipe fitting elbow

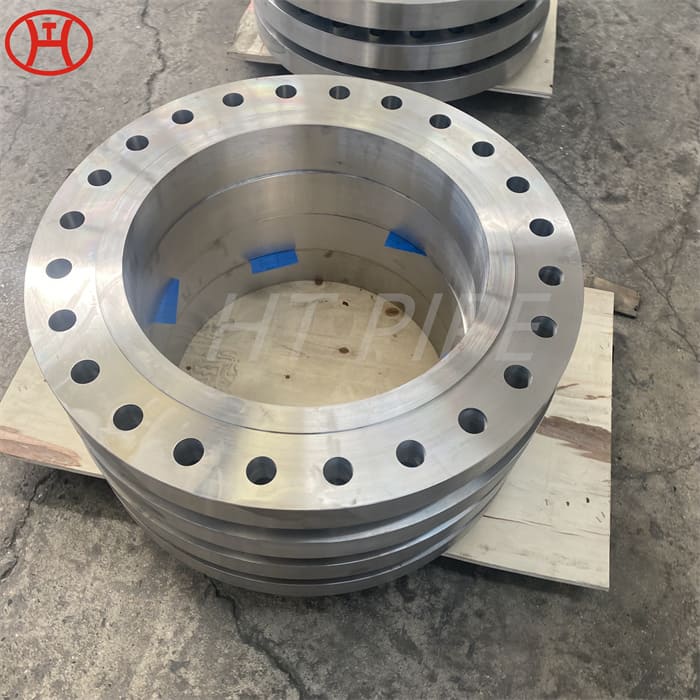

321 Fittings cover the standard for wrought austenitic stainless steel fittings for pressure piping applications. The material of pipe fittings shall include forgings, bars, plates or seamless or welded pipes. Forging or forming operations shall be performed by hammering, pressing, piercing, extruding, upsetting, rolling, bending, fusion welding, machining, or a combination of two or more of these operations. All accessories should be heat treated.

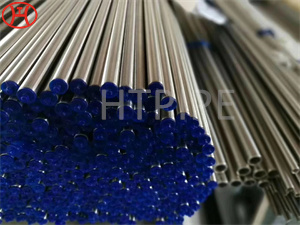

Alloy 321 (UNS S32100) is a titanium-stabilized austenitic stainless steel with good general corrosion resistance. The 321 stainless steel pipe fitting has excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800–1500°F (427–816°C). Stainless Steel 321 Pipe Fittings are resistant to oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L. 321 stainless steel fitting also has good low temperature toughness. At the same time, SS 321 is the most useful and demanding grade in the stainless steel family due to its excellent properties and general use in highly corrosive environments.

321 stainless elbows are installed between two lengths of pipe to allow a change of direction. Usually 90° or 45° elbows are available, a 90º elbow is also known as a “90 bend”, “90 ell” or “quarter bend” and a 45° elbow is also known as a “45 bend” or “45 ell”. 321 stainless steel elbows are also categorized by length. The radius of curvature of a long-radius elbow is 1.5 times the pipe diameter, but a short-radius elbow has a radius equal to the pipe diameter. Astm a403 wp321 pipe fittings cannot be hardened by heat treatment, only by cold working. By standard shop fabrication practices it can be easily welded and processed.

Also, these 1 1/2″ a403 gr wp321 elbows can withstand the punishment, vibration and heat of high horsepower street, drag or rail cars. Our 321 stainless butt welded pipe fittings, commonly referred to as welded pipe fittings or welded pipe fittings, are the manufacturer’s choice when manufactured Turbine Manifolds, Dump Pipes and Exhaust Downpipes. With maximum operating temperature ratings from 1598°F to 1652°F and wall thickness options from 0.065″ to 0.203″, our line of welds will help reduce Risk of cracking under the most extreme conditions.

Standard Product TyPes Size

ASME B16.9 Long Radius Elbows,Long Radius Reducing Elbows,Long Radius Returns,Short Radius Elbows,Short Radius 180-deg Rerurns,3D elbows,Straight Tees,Straight Crosses,Reducing Outlet Tees,Reducing Outlet Crosses,Lap Joint Stub Ends,Caps,Reducers Size:1/2″-48″ Wall thickness:SCH5S-SCHXXS

ASME B16.28 Short Radius Elbows,Short Radius 180-deg Returns Size:1/2″-24″ Wall thickness:SCH5S-SCHXXS

ASME B16.49 30¡ã 45¡ã 60¡ã 90¡ã Long Radius Short Radius Bend Size:1/8″-12″ Wall thickness:SCH5S-SCHXXS

MSS-SP43 Long Radius Elbows,Straight and Reducing-on-the-Outlet Tees,Lap Joint Stub ends,caps,long radius 180 Degree returns,concentric reducers,eccentric reducers Size:1/2″-24″ Wall thickness:SCH5S-SCHXXS

MSS-SP75 Long Radius Elbows,3R elbows,straight tees,reducing outlet tees,caps,reducers Size:16″-60″ Wall thickness:SCH5S-SCHXXS

ISO, DIN, JIS All Kind of Buttwelding Product or as Client’s Drawing As the Client’s Demand

Material Stainless Steel ASTM/ASME SA403 WP 304, WP 304L, WP 304H, WP 304LN, WP 304N, ASTM/ASME A403 WP 316, WP 316L, WP 316H, WP 316LN, WP 316N, WP 316Ti, ASTM/ASME A403 WP 321, WP 321H ASTM/ASME A403 WP 347, WP 378H