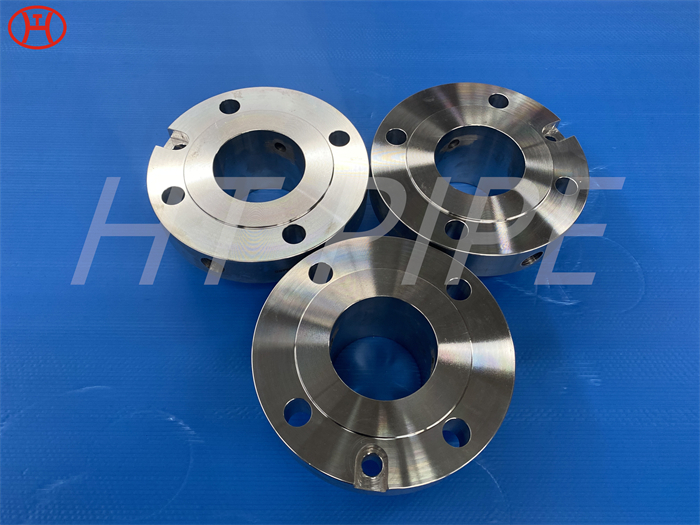

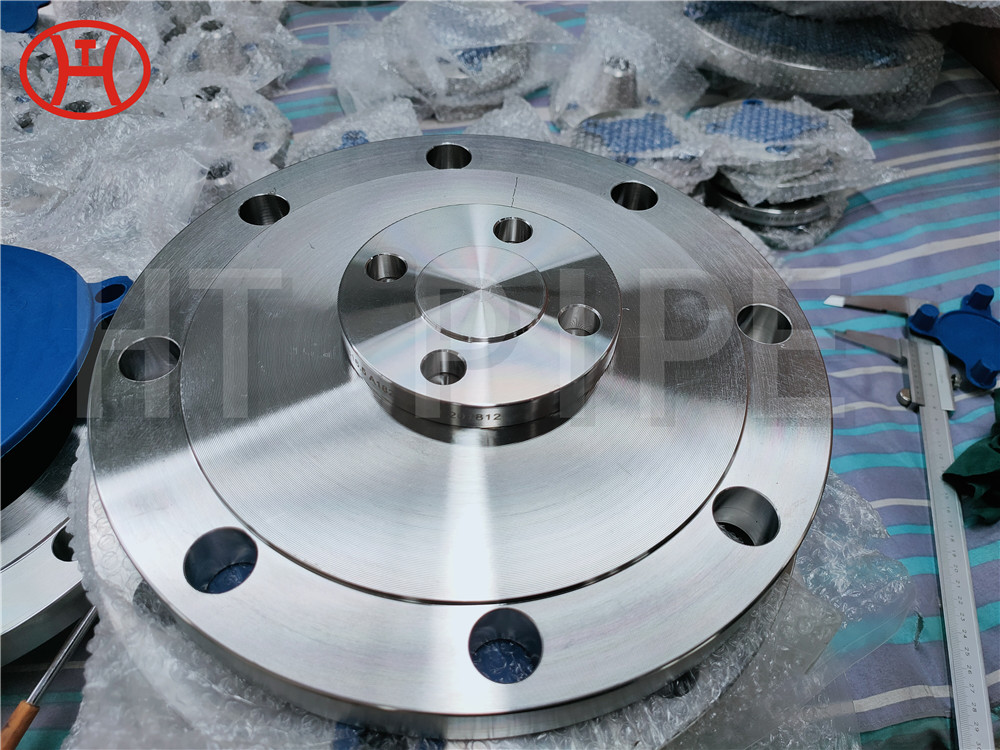

A182 F316L special flange finish and superior corrosion resistance

316L is best known among manufacturers for crack resistance after the welding process is complete. This makes the 316L the first choice for manufacturers looking to build metal structures for industrial applications.

Known for their excellent weldability, these alloys are joined by fusion and resistance processes. The 316L low carbon version is preferred in corrosive environments. It is important to ensure that the copper and zinc do not become contaminants at the weld as this can create cracking. Type 316L can be dual certified as 316 when the composition meets the carbon lower limit of 316L and the slightly higher strength level of 316. Type 316L should be specified for welding applications as the low carbon version eliminates chromium carbide precipitation and enhances corrosion resistance to the welded state.