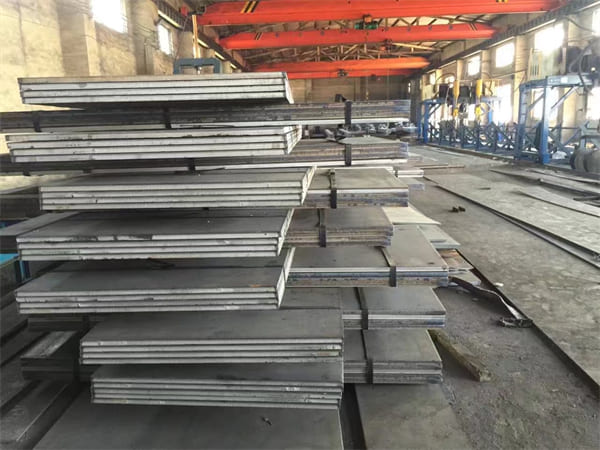

ASTM B575 UNS N10276 2.4819 Hastelloy C276 Plate Sheet Coil

Hastelloy C276 is a corrosion-resistant nickel-molybdenum-chromium alloy that is widely used in a variety of industrial applications, particularly in environments where strong acids and oxidizing agents are present.

ASTM B575 UNS N10276 2.4819 Hastelloy C276 Plate Sheet Coil, Hastelloy C276 Sheets, C276 Hastelloy Plates, Hastelloy C276 Industrial Sheet, UNS N10276 Sheets, Hastelloy Alloy C276 Coils, 2.4819 Sheets, Hastelloy Alloy C276 Plates, Hastelloy C276 Strips, Hastelloy NW 0276 Plates, Hastelloy C276 Foils

Hastelloy C276 is a corrosion-resistant nickel-molybdenum-chromium alloy that is widely used in a variety of industrial applications, particularly in environments where strong acids and oxidizing agents are present.

UNS N10276 Sheet has outstanding resistance to a wide variety of chemical process environments including ferric and cupric chlorides, hot contaminated mineral acids, solvents, chlorine and chlorine contaminated (both organic and inorganic), dry chlorine, formic and acetic acids, acetic anhydride, sea water and brine solutions and hypochlorite and chlorine dioxide solutions. Hastelloy Alloy C276 Coil also resists formation of grain boundary precipitates in the weld heat affected zone making it useful for most chemical processes in the as-welded condition. 2.4819 Sheet has excellent resistance to pitting and stress corrosion cracking.

The low carbon minimizes carbide precipitation in UNS N10276 plate during welding to maintain resistance to intergranular attack in heat-affected zones of welded joints. W.Nr. 2.4819 Sheet is used in chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment and the recovery of “sour” natural gas.

ASTM B575 UNS N10276 2.4819 Hastelloy C276 Plate Sheet Coil is a flat sheet of this alloy that is produced in various thicknesses and sizes. Hastelloy C276 Strip is commonly used in the construction of chemical processing equipment, as well as in the production of heat exchangers, pressure vessels, and other high-stress components that require excellent resistance to corrosion and high temperatures.

The applications of Hastelloy C276 Industrial Sheet also includes air pollution control include stack liners, ducts, dampers, scrubbers, stack-gas re-heaters, fans and fan housings. In chemical processing, Hastelloy NW 0276 Plate is used for components including heat exchangers, reaction vessels, evaporators and transfer piping.

ASTM B575 UNS N10276 2.4819 Hastelloy C276 Plate Sheet Coil is available in both standard and customized sizes, and it can be cut, shaped, and welded to meet specific project requirements. It is typically manufactured according to industry standards such as ASTM B575, ASME SB-575, and UNS N10276. The NiMo16Cr15W Hastelloy Sheet may be supplied in annealed or tempered condition, depending on the application requirements.

Chemical Composition of Hastelloy C276 Sheets & Plates

| Grade | C | Mn | Si | S | Co | Ni | Cr | Fe | Mo | P |

| C276 | 0.010 max | 1.00 max | 0.08 max | 0.03 max | 2.50 max | 50.99 min* | 14.50 – 16.50 | 4.00 – 7.00 | 15.00 – 17.00 | 0.04 max |

Mechanical Properties of Hastelloy B575 C276 Sheets & Plates

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Hastelloy C276 | 8.89 g/cm3 | 1370 °C (2500 °F) | Psi – 1,15,000 , MPa – 790 | Psi – 52,000 , MPa – 355 | 40 % |