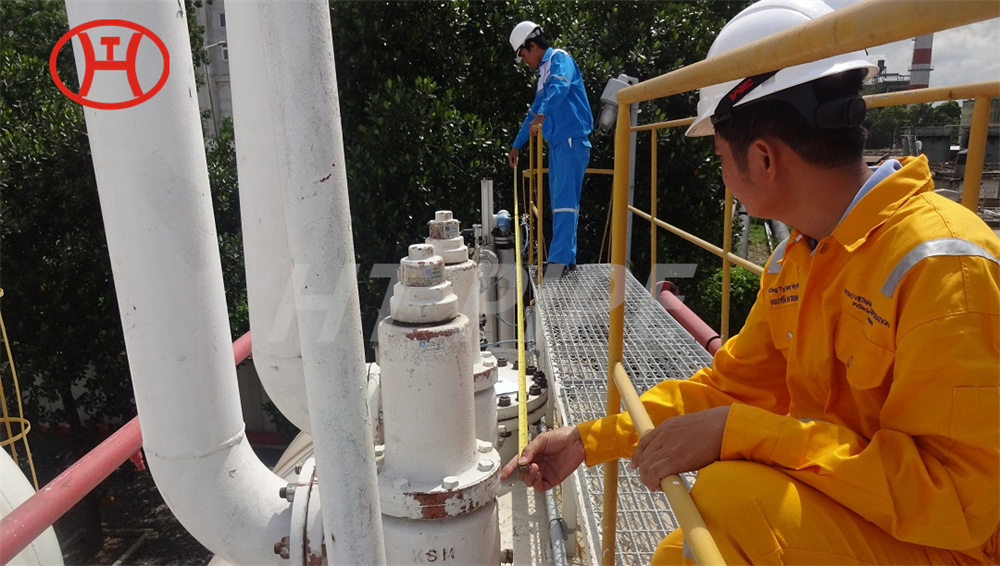

Hastelloy B2 pipe bend in the chemical process industry involving sulfuric phosphoric hydrochloric and acetic acid

HASTELLOY(r) B-2 is a wrought nickel-molybdenum alloy that can be used in the ¡®as welded¡¯ condition.

The ASTM B622 Hastelloy B2 pipe bend especially is known to exhibit excellent resistance to corrosion in aggressive reducing media such as hydrochloric acid. Not only is the ASTM B622 specified Hastelloy B2 Custom Pipe resistant to hydrochloric acid, but it has the ability to resist corrosion in a wide range of temperatures and concentrations, as well. Alloy B (UNS N10001) was developed to resist hydrochloric acid. Hastelloy B2 pipe bend has replaced it. Alloy B3 (UNS N10675), a newer variant, shows greater thermal stability. However, its popularity is hampered by its availability. All of these materials resist reducing acids well, but oxidizing acids poorly. Hastelloy B2 pipe bend are screw manufactured from alloy containing nickel as base element containing chromium and Molybdenum with additions of tungsten and cobalt. Hastelloy B2 Fasteners have enhanced resistance to pitting, crevice corrosion and stress corrosion cracking.