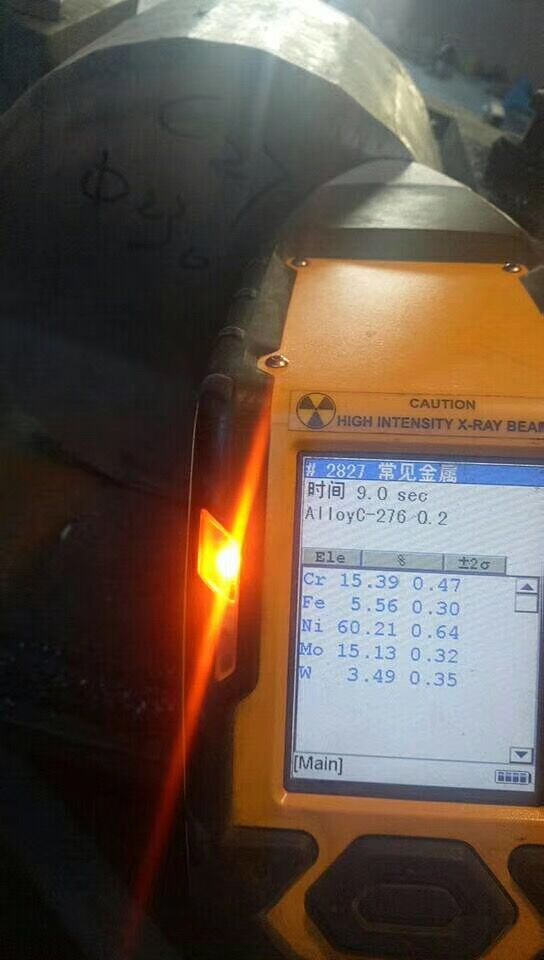

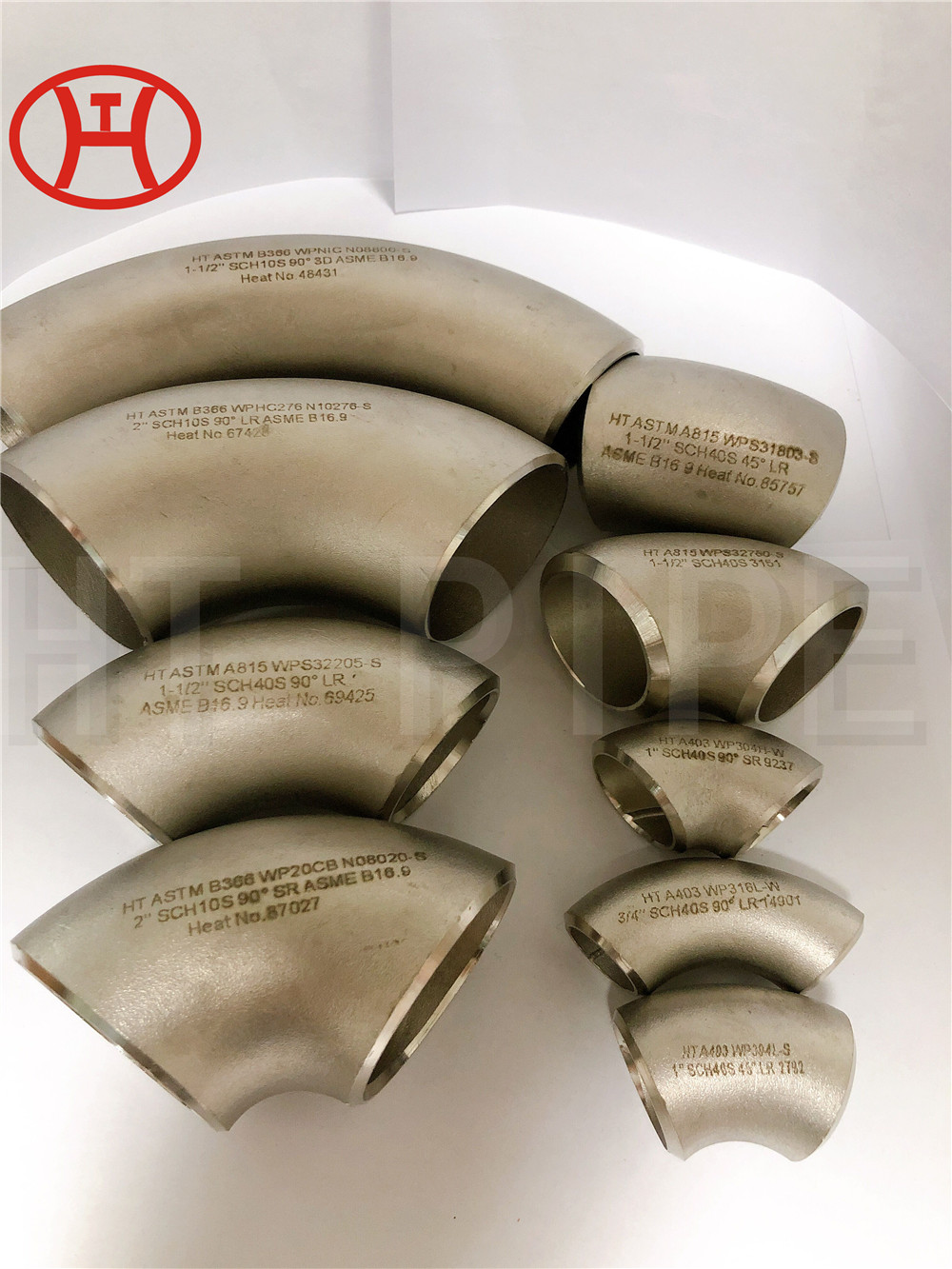

hastelloy c22 pipe N06022 2.4602 steel pipe

Alloy 22 (UNS N06022) is the most versatile Nickel Chromium Molybdenum Tungsten alloy with controlled Iron. Due to Alloy 22’s content this alloy exhibits excellent resistance to both oxidising and reducing acid environments as well as those containing mixed acids.

Nickel & cobalt base corrosion, temperature and wear resistant alloys are classified as moderate to difficult when machining, however, it should be emphasized that these alloys can be machined using conventional production methods at satisfactory rates. During machining these alloys work harden rapidly, generate high heat during cutting, weld to the cutting tool surface and offer high resistance to metal removal because of their high shear strengths. The following are key points which should be considered during machining operations:

CAPACITY Machine should be rigid and overpowered as much as possible.

RIGIDITY Work piece and tool should be held rigid. Minimize tool overhang.

TOOL SHARPNESS Make sure tools are sharp at all times. Change to sharpened tools at regular intervals rather than out of necessity. A 0.015 inch wear land is considered a dull tool.

TOOLS Use positive rake angle tools for most machining operations. Negative rake angle tools can be considered for intermittent cuts and heavy stock removal. Carbide tipped tools are suggested for most applications. High speed tools can be used, with lower production rates, and are often recommended for intermittent cuts.

POSITIVE CUTS Use heavy, constant, feeds to maintain positive cutting action. If feed slows and the tool dwells in the cut, work hardening occurs, tool life deteriorates and close tolerances are impossible.

HT PIPE as the Hastelloy C22 pipe Suppliers, offers Hastelloy C22 pipes are highly recommended for their excellent resistance to all types of corrosion, including pitting, crevice corrosion, and stress corrosion cracking. They can handle severe chemical environments, including strong oxidizers such as ferric and cupric chlorides, chlorine, hot contaminated mineral acids, solvents, and wet chlorine gas.