Stainless Steel ASTM A213 TP904L Seamless Tubes Dealer ASTM A312 TP904L Seamless Pipes

UNS NO8904, commonly known as 904L, is a low carbon high alloy austenitic stainless steel which is widely used in applications where the corrosion properties of AISI 316L and AISI 317L are not adequate.

904L stainless steel erw pipe dimensions, 904L stainless steel pipes weight, Stainless steel 904l pipes sizes, Stainless steel wnr 1.4539 pipes exporter in China, 904L stainless steel pipes specification, 904L ss b677 seamless pipe sizes, SS 904L pipes suppliers, 904L stainless steel pipes price, Thin wall steel 904l pipe

SS 904L Seamless Pipe has a greater resistance to precipitation of ferrite and sigma phases on cooling and welding than other stainless steels containing molybdenum such as 316L and 317L. There is no risk of intercrystalline corrosion on cooling or welding due to the low carbon content. Its maximum service temperature is at 450¡ãC. SS 904L Welded Pipe is made of high-alloy austenitic stainless steel with low carbon content.

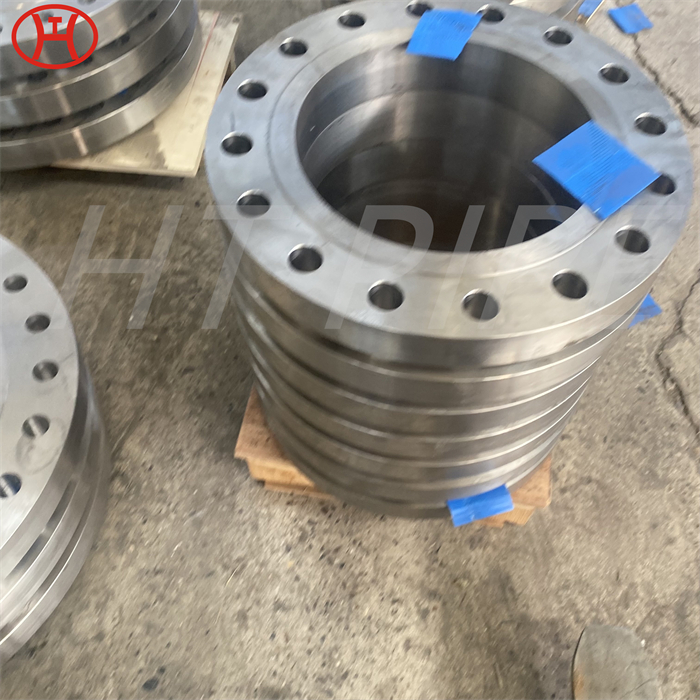

The UNS NO8904 is intended for use under severe corrosive conditions. The 1.4539 tube was originally developed to resist corrosion in dilute sulfuric acid and has been proven effective in this application over many years. Alloy 904 & 904L (N08904) stainless steel pipe, fittings and flanges are used in the chemical industry to process corrosive chemicals such as: Acetic acid, Acetylene, Acrylates, Acrylonitrile, Aluminum sulfate, Ammonium phosphate, Ammonium sulfate, Battery acid, Benzene, Butyl acetate, Caprolactum, Cellophane, Citric acid, Nitrophosphate, Oxalic acid, Superphosphate, Tall oil, Tartaric acid, Uranium oxide and Zinc sulfate.

In this concentration range, the corrosion resistance of 904L is better than that of conventional stainless steel. SS 904L pipe has high resistance to pitting corrosion. Its crevice corrosion resistance in chloride solution is also very good. The high nickel content of UNS NO8904 reduces the corrosion rate at the pits and crevices. Ordinary austenitic stainless steel may be sensitive to stress corrosion in a chloride-rich environment when the temperature is higher than 60 degrees Celsius. By increasing the nickel content of stainless steel, this sensitization can be reduced. Due to the high nickel content, 904L 1.4539 stainless steel tube has high resistance to stress corrosion cracking in chloride solution, concentrated hydroxide solution and hydrogen sulfide environment.

| Specification | |

| Size | OD: 10.0 ~ 1219mm; WT: 0.5 ~ 100mm; Length: 5.8m, 6m, 11.8m, 12m, Max.18m |

| Process | Seamless, Cold Drawn, Cold Rolled, Hot Rolled |

| End | PE(Plain End), BE(Beveled End), NPT, BW(Butt Weld End) |

| Surface | Aid Pickling, Polishing, Brushing |

| Standard | ASTM B677 |

| Theoretical Weight(kg/m) | Weight/meter = (OD-WT)*WT*0.02507 Both OD and WT in mm. |

| Materials and Manufacture | 904L pipe shall be supplied in the solution-treated condition. (The recommended heat treatment shall consist of heating to a temperature of 1065 to 1150℃) |