6 inch elbow stainless steel pipe fitting elbows

Stainless steel pipe fittings are widely used in manufacturing for their durability and cost-effectiveness. It has many advantages over traditional pipe fittings that make it more popular than any other. The cost-effectiveness of alloy products has greatly facilitated their widespread use. In addition to this, it also helps with the maintenance of the plumbing system.

Manufacturer of ASTM A403 WP 304 Elbow, Check Dimensions of UNS S30400 Stub End, Buy SS 304 Pipe Fittings from Suppliers, Ask For ready stock of UNS S30400 Pipe Elbow

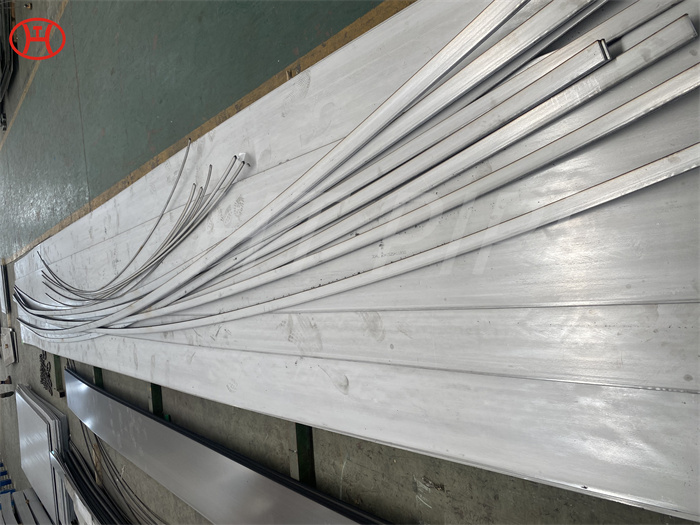

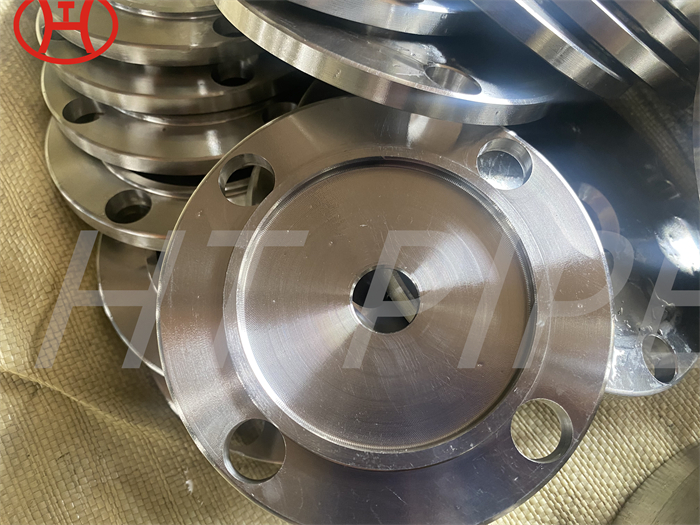

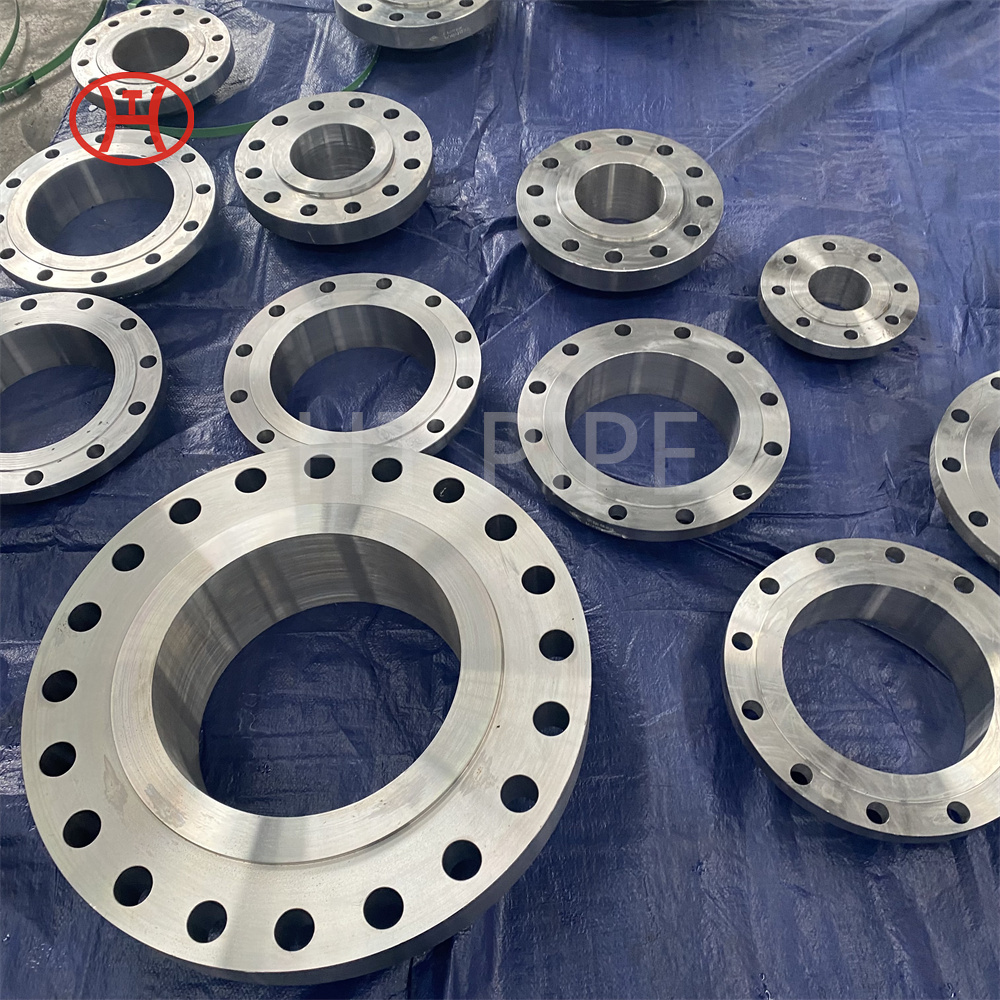

Stainless Steel 304 Pipe Fittings are made up of 18/8 chromium nickel alloy steels. The ASTM A403 WP 304 Elbow has 18% chromium and 8%nickel in its composition. UNS S30400 Elbow makes the material to be stronger with 215MPa minimum yield strength and 505MPa minimum tensile strength. The combination makes the material corrosion resistant and high temperature capable up to 889 degrees Celsius. HT PIPE is a manufacturer and supplier of these fittings. The 304 Stainless Steel Buttweld Fittings come under the standard ASTM A403 and the outer diameters range from ½ inches to 48 inches. For seamless fittings, the diameters range from ½ to 10 inches. There are different types such as the SS 304 Pipe Fittingswhich is used to change the direction of flow and the SS WERKSTOFF NR. 1.4301 Tee which is used to connect three pipes at one junction.

A tensile strength of 75 ksi that guarantees supreme dexterity, with a load bearing capacity high enough to work under constant pressure, our ASTM A403 SS 304 Elbow have resistance to atmospheric corrosion and serve general purposes like sealing pipe ends and preventing any contamination to the internal fluids.Our ASME SA403M SS 304 Reducer are demanded highly by the printing and textile industry due to their versatility and excellent weldability. We are suppliers and exporters of SS UNS S30400 Equal Tee that are manufactured with threaded ends that connect to pipes and tubes without welding, thus cutting cost. Also We offer wide range of stainless steel ASTM A403 WP304 pipe fittings such as SS WP304 tee, WP304 SS End Pipe Cap, SS 304 reducer, SS 304 cross, SS 304 elbow, SS 304 stub ends etc.

Specification List of Stainless Steel 304 Pipe Fittings

| Specifications | ASTM A403 |

| Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| size | Seamless Butt Weld Fittings: 1/2″ – 10″ |

| Welded Butt Weld Fittings: 1/2″ – 48″ | |

| Type | DN15-DN1200 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom MSS Sp-43 Stainless Steel Pipe Fitting |

| Size Range | ½” NB to 24″ NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) ASTM A403 Stainless Steel Buttweld Fitting |

| Elbows | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D, 3D, 4D, 5D, 6D, 7D-40D . |

| Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO | |

| Connection | Welding |

| Manufacturing process | Forge, Cast, Push, Press, etc. |

| Origin & Mills | Indian, USA, Korean, Japanese, European, Ukraine, Russian |

| Key markets and industries | Bitumen upgraders. |

| Heavy oil refineries. | |

| Petrochemicals and acids. | |

| Nuclear power (mostly seamless). | |

| Test Certificates | EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc | |

| Specialized manufacturer of | 90º Elbows, 45º Elbows, Tees, Crosses, Reducers, Pipe Cap, Stub End, Pipe Bend |

| Application & uses | Fittings To Connect Pipe & Tubes in Petroleum, Power, Chemical, Construction, Gas, Metallurgy, Shipbuilding etc |

| Schedule 10 fittings are an economical alternative for lower-pressure applications. | |

| Schedule 40 fittings have a thicker wall for higher-pressure applications. | |

| We provide Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |