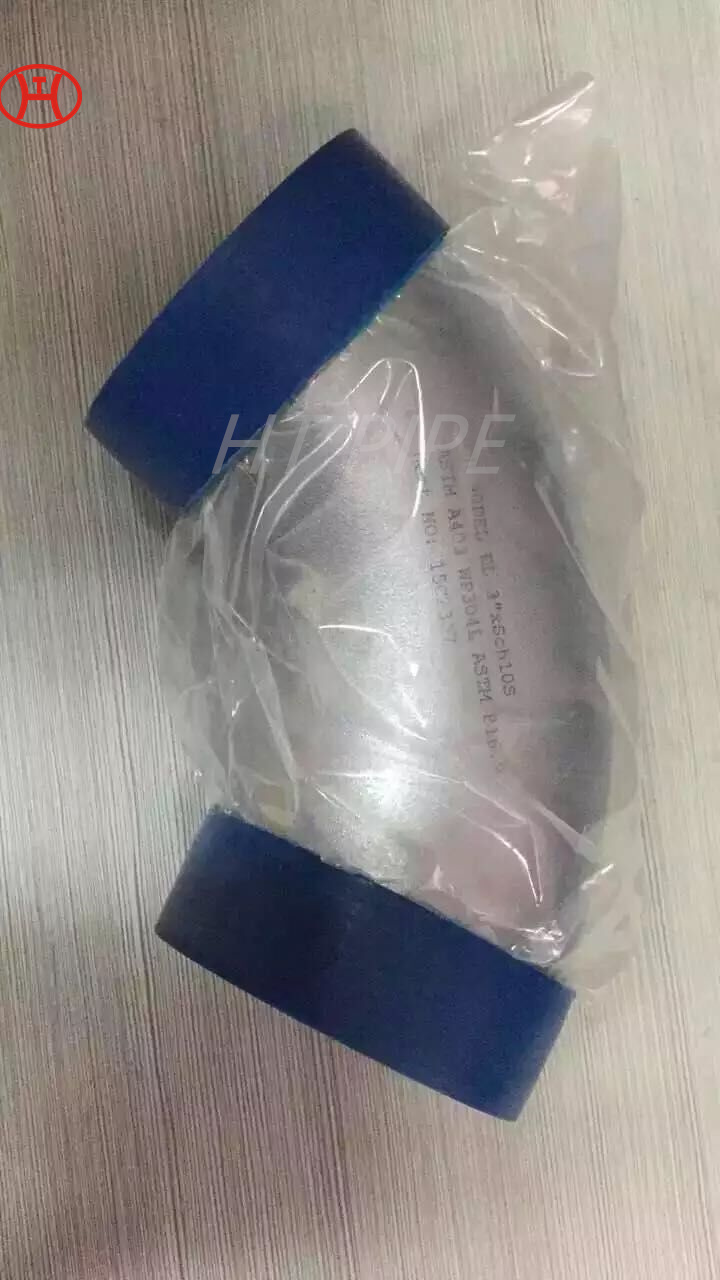

90 degree duplex steel long sweep adjustable S32760 elbow pipe fitting

These super duplex fittings products are designed in accordance with national and international standard specifications. These Super Duplex Steel S32750 Seamless Fittings and Super Duplex Steel S32750 Welded Fittings are widely used in various application industries such as automotive, chemical, marine, power plants, heavy engineering, etc.

Manufacturer and exporter of Super Duplex 2507 pipe fittings in China, wide range of SA 815 Grade UNS S32750 Cross, Stub Ends, 3D/ 5D Bend, U Bend

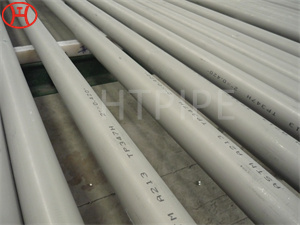

ASTM A815 UNS S32760 Fitting is a fitting with good strength and corrosion resistance. Ductility is excellent in this regard, and these are used in industries such as chemical, oil and gas refineries. It includes many chemical compositions and mechanical properties.

At the same time, super duplex pipe fitting is a kind of pipe fitting with good strength and corrosion resistance. Ductility is excellent in this regard, and these are used in industries such as chemical, oil and gas refineries. It includes many chemical compositions and mechanical properties.

If custom dimensioned Super Duplex S32760 Fittings or Super Duplex S32760 Butt Welded Fittings are welded by qualified personnel to perfectly weld and fabricate 2507 Super Duplex Fittings on large projects in the oil and gas industry to extend the life of the product.

Super Duplex pipe fittings are very highly resistant to general corrosion and to pitting and crevice corrosion in high chloride, hot environments. It is not recommended for temperatures below -50°C or above +300°C, because of reduced toughness outside this range.

Super Duplex Fittings has high resistance to intergranular corrosion and very high resistance to stress corrosion cracking in both chloride and sulphide environments. It can be fabricated by the process of cutting, bevelling, and welding. If Super Duplex Stainless Steel Pipe Fittings becomes embrittledit can only be rectified by a full solution annealing treatment. It cannot be hardened by thermal treatment.

We are also Swagelok Super Duplex Fittings Dealers and Parker Super Duplex Fittings Distributor. It is available in standard as well as in customized dimensions as per the requirement.

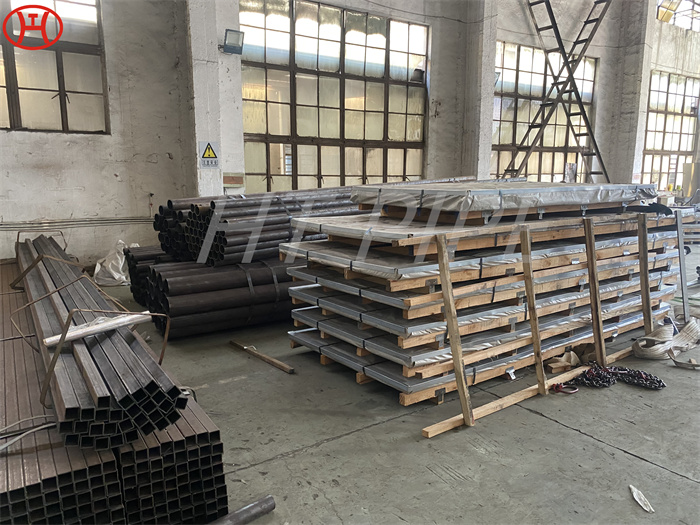

Super Duplex Pipe and Fittings are classified as “welded” or “pressure” fittings. Welded fittings are welded on to the piping system where as pressure fitting uses National Pipe Thread in order to connect to the pipe. Pressure fittings are classified as 3000#, 6000# or 9000#.

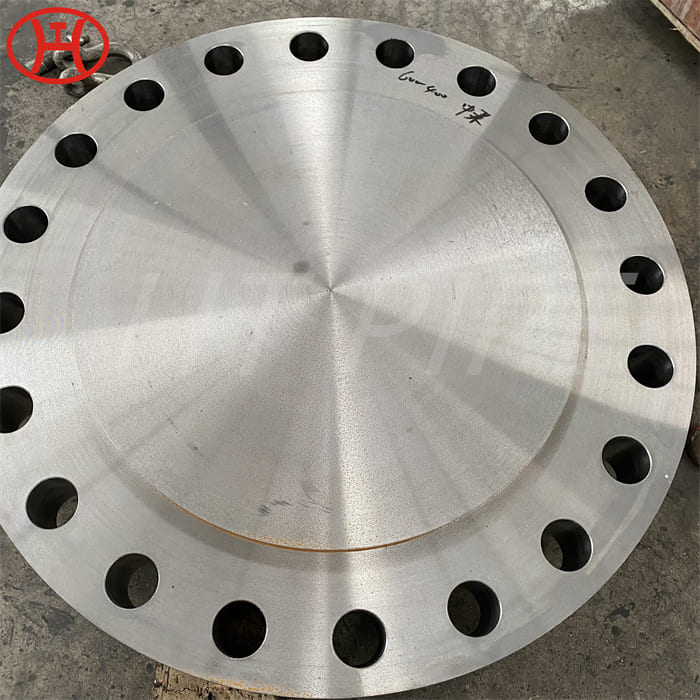

Standard Product Type Size

ASME B16.9 Long Radius Elbows,Long Radius Reducing Elbows,Long Radius Returns,Short Radius Elbows,Short Radius 180-deg Rerurns,3D elbows,Straight Tees,Straight Crosses,Reducing Outlet Tees,Reducing Outlet Crosses,Lap Joint Stub Ends,Caps,Reducers Size:1/2″-48″ Wall thickness:SCH5S-SCHXXS

ASME B16.28 Short Radius Elbows,Short Radius 180-deg Returns Size:1/2″-24″ Wall thickness:SCH5S-SCHXXS

ASME B16.49 30¡ã 45¡ã 60¡ã 90¡ã Long Radius Short Radius Bend Size:1/8″-12″ Wall thickness:SCH5S-SCHXXS

MSS-SP43 Long Radius Elbows,Straight and Reducing-on-the-Outlet Tees,Lap Joint Stub ends,caps,long radius 180 Degree returns,concentric reducers,eccentric reducers Size:1/2″-24″ Wall thickness:SCH5S-SCHXXS

MSS-SP75 Long Radius Elbows,3R elbows,straight tees,reducing outlet tees,caps,reducers Size:16″-60″ Wall thickness:SCH5S-SCHXXS

ISO, DIN, JIS All Kind of Buttwelding Product or as Client’s Drawing As the Client’s Demand

Material Stainless Steel ASTM/ASME SA403 WP 304, WP 304L, WP 304H, WP 304LN, WP 304N, ASTM/ASME A403 WP 316, WP 316L, WP 316H, WP 316LN, WP 316N, WP 316Ti, ASTM/ASME A403 WP 321, WP 321H ASTM/ASME A403 WP 347, WP 394H