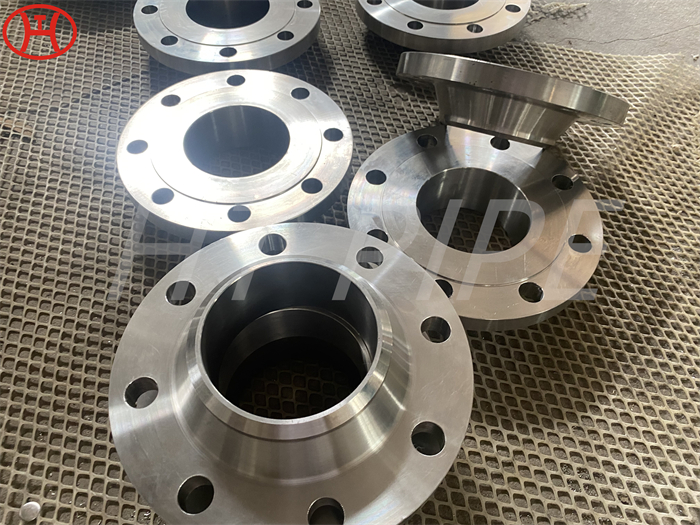

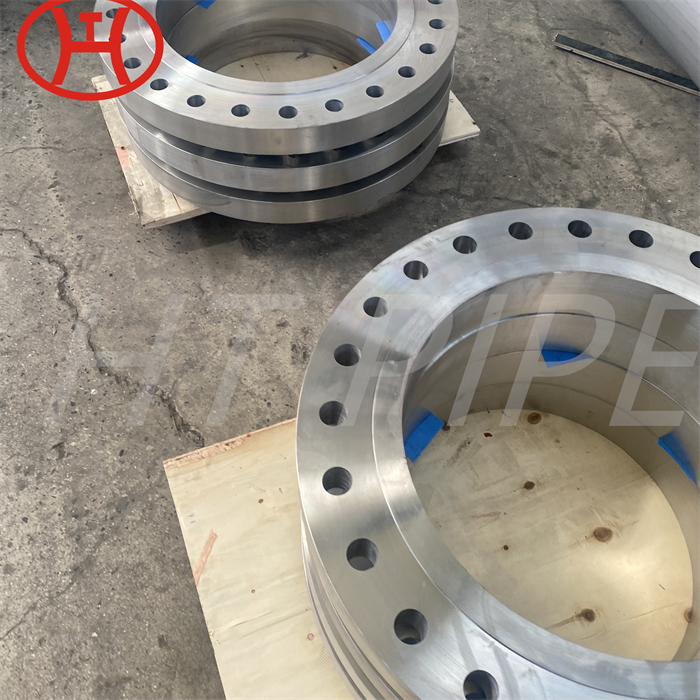

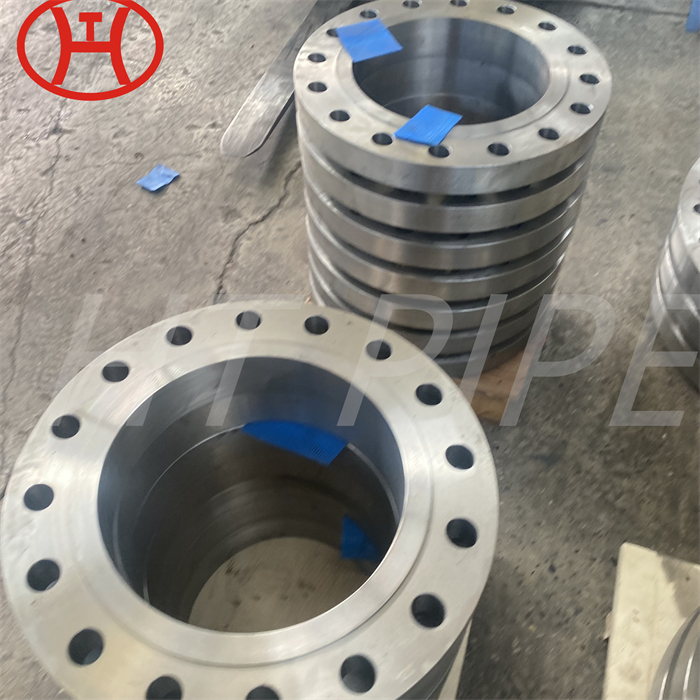

Incoloy 925 Stainless Steel Flange as an alloy for higher temperature applications

Incoloy 925 flange is often used for down-hole and surface gas-well because of their excellent resistance to sulfide stress cracking and stress-corrosion cracking in ¡°sour¡± (H2S containing) crude oil and natural gas.

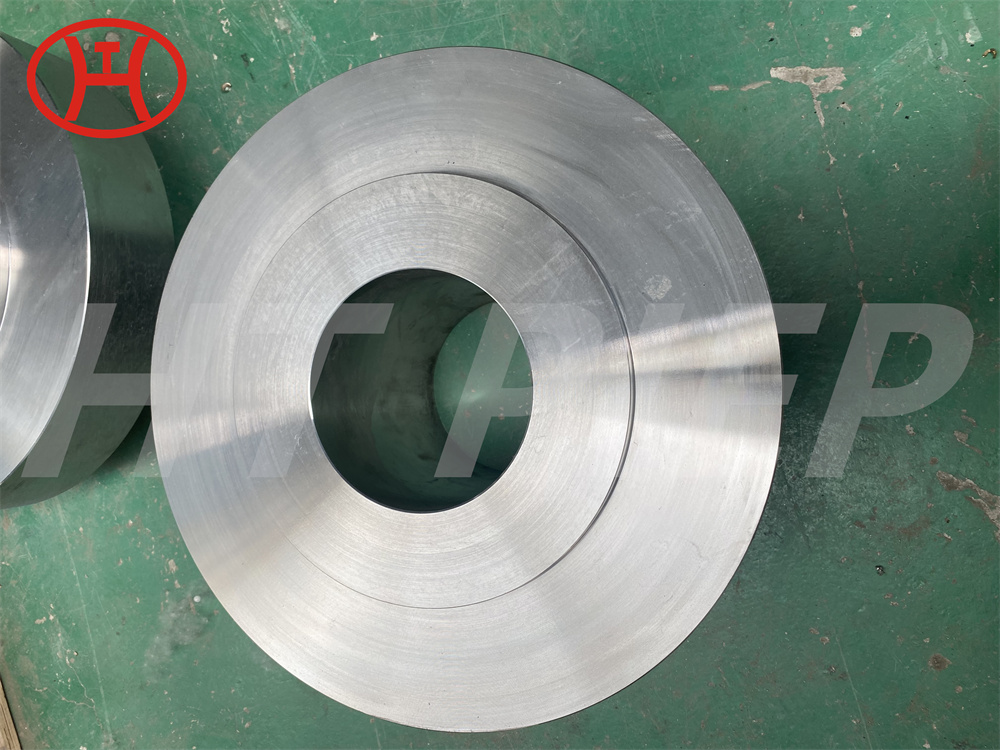

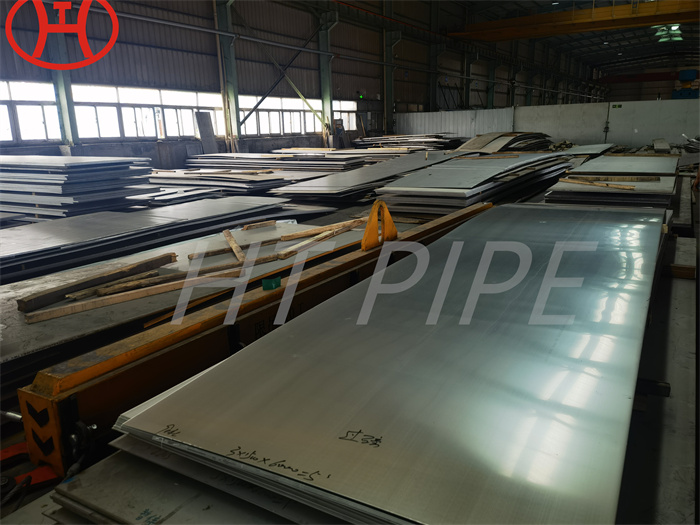

Incoloy 925 RTJ Flanges are ideal to be used in applications that need a mixture of high strength and corrosion resistance. Incoloy 925 Socket Weld Flanges is produced by a vacuum re ¡ª melt process, but are often supplied using an air melt single consumable electrode practice if the fabric specification allows. It is super alloy of Nickel, Iron, and Chromium which is also known as a precipitation-hardenable alloy with copper and molybdenum. This grade has qualities like excellent resistance to pitting, stress-corrosion cracking, crevice corrosion, high strength, and resistance to many aqueous environments which contains chlorides and sulphides. With all features and qualities, we are manufacturing excellent quality Flanges.