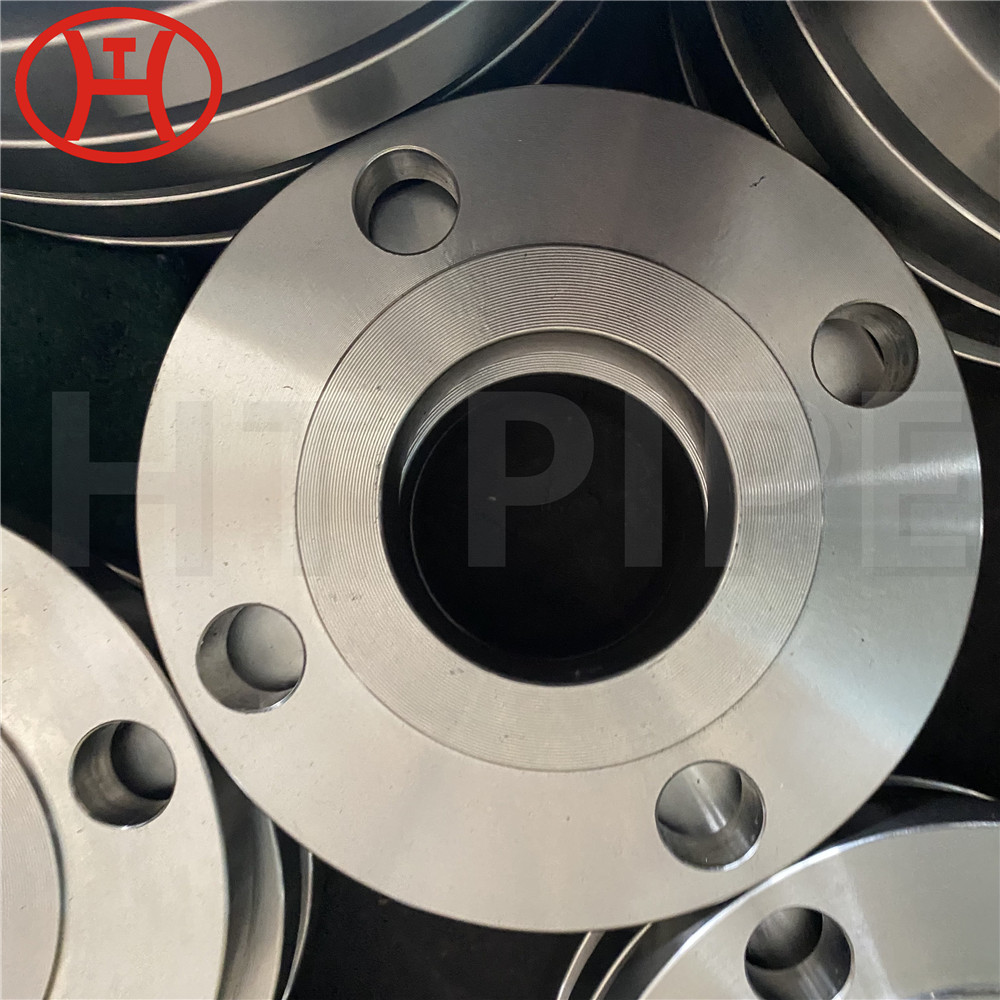

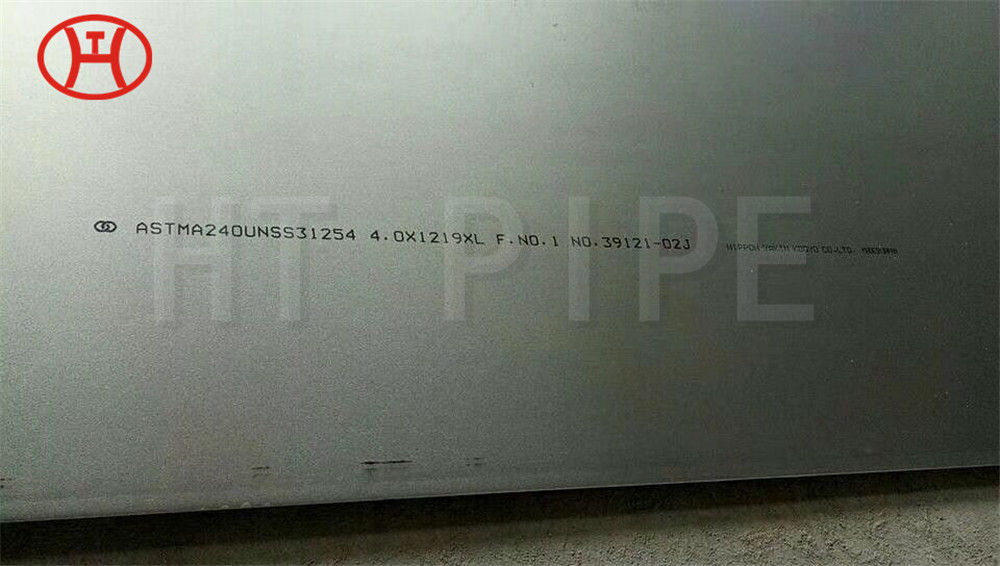

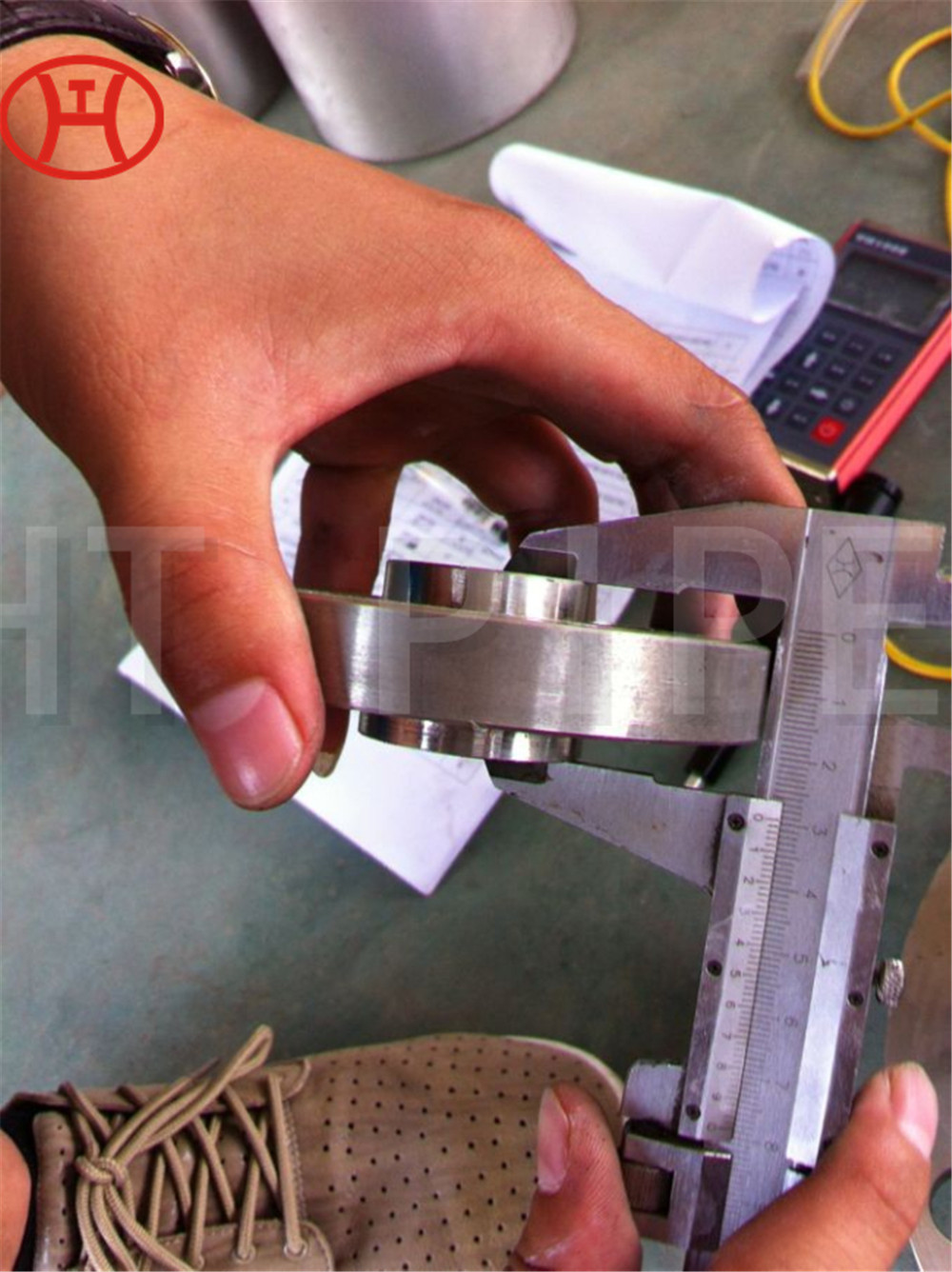

N08367 Stainless Steel Plate Flange Stainless Steel Alloy AL6XN Threaded Flanges

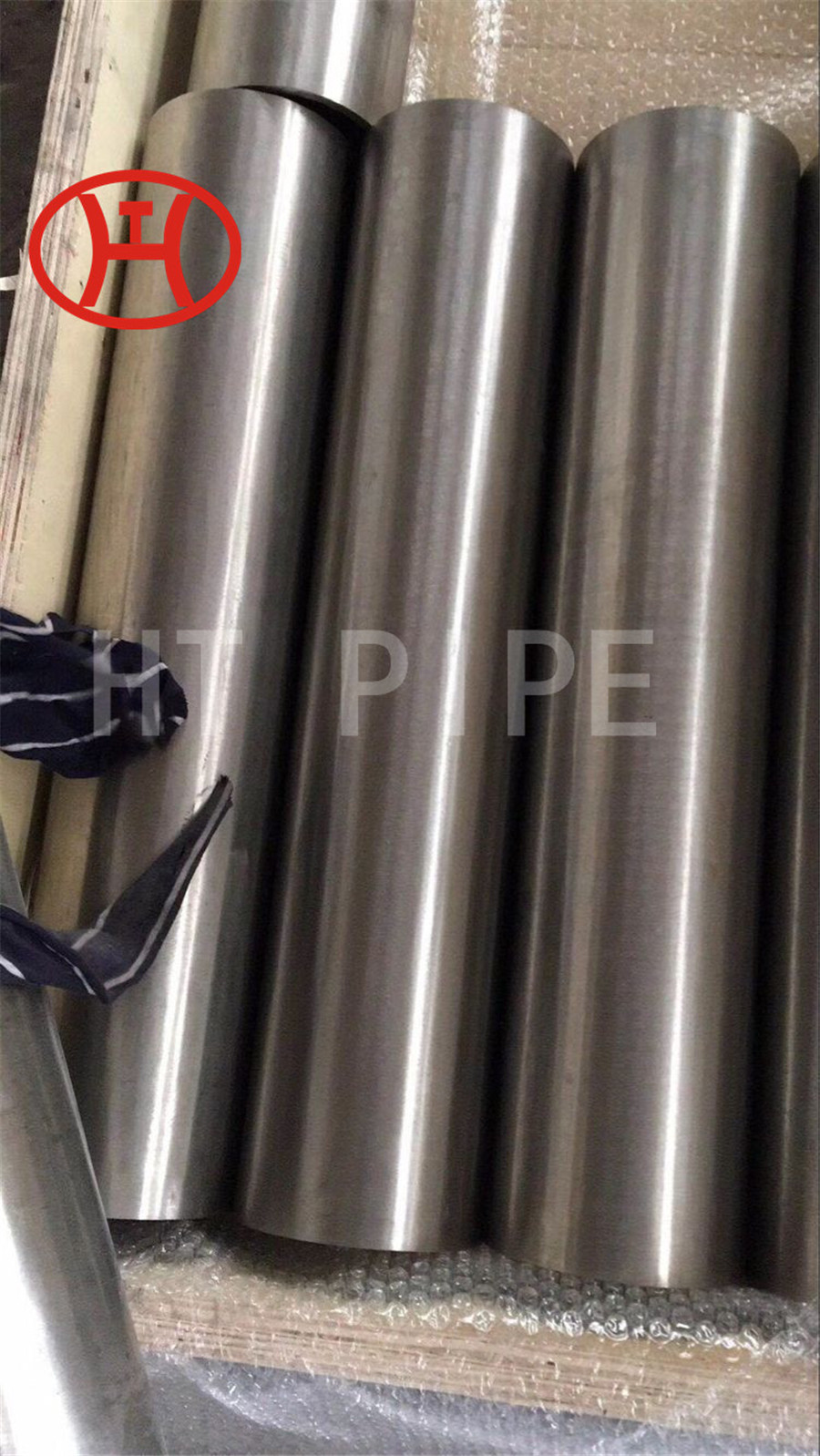

AL-6XN alloy (UNS N08367) is a low carbon, high purity, nitrogen-bearing ¡°super-austenitic¡± stainless alloy. The AL-6XN alloy was designed to be a seawater resistant material and has since been demonstrated to be resistant to a broad range of very corrosive environments.

The AL-6XN Stainless Steel Flanges are made of a superaustenitic stainless steel which was designed by HT PIPE. It bestows far greater resistance to chloride pitting, crevice corrosion and stress corrosion cracking than exhibited by the standard 300 series stainless steels, and is less costly than the traditional nickel-base corrosion resistant alloys. Its UNS Designation of the AL-6XN alloy is N08367. The ¡°superalloy¡± is resistant to attack by corrosive food and beverage products such as: sports drinks, ketchups, soy and barbecue sauces, and salsas. The high nickel (24%) and molybdenum (6.3%) contents of the AL-6XN Stainless Steel Flange give it great resistance to chloride stress-corrosion cracking. The molybdenum confers resistance to chloride pitting. In addition, the nitrogen content of AL-6XN alloy serves to further increase pitting resistance and also gives it higher strength than typical 300 series austenitic stainless steels, and thereby often allows it to be used in thinner sections. AL-7XN¡¯s high levels of chromium, molybdenum and nitrogen serve to produce exceptional corrosion resistance for this formable and weldable stainless alloy.