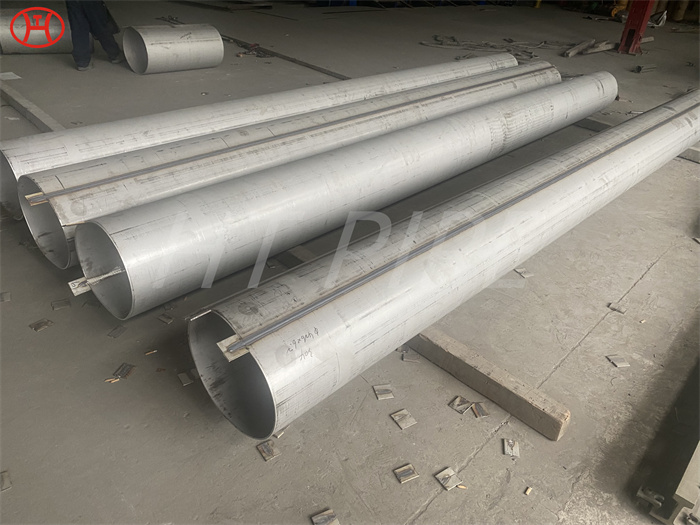

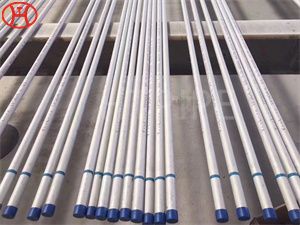

super duplex tube 10mm coil tube 1.4410 1.4501 coil

S32760 was originally developed as a seawater resistant material for pump applications in the North Sea.

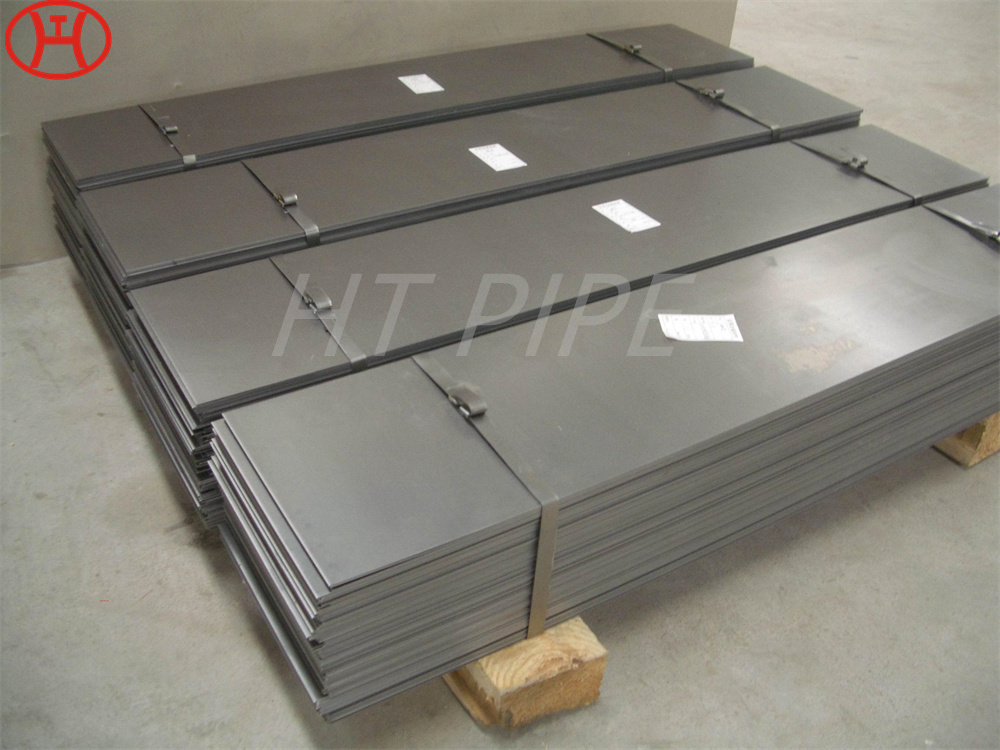

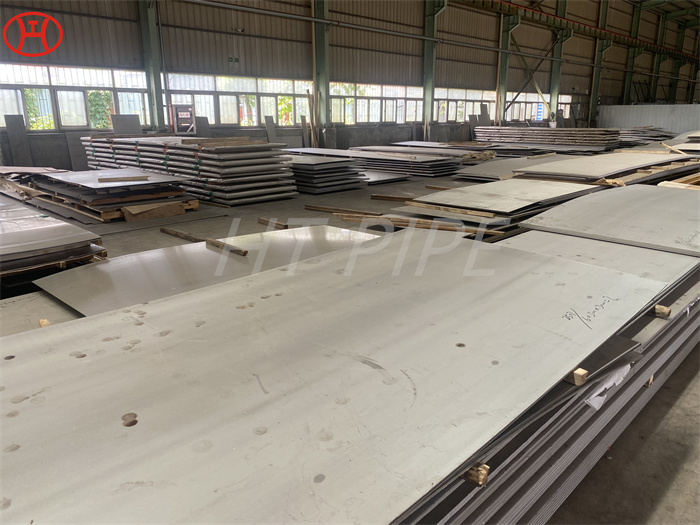

Following its success, it became an ideal material for a wide range of uses, including oil and gas applications, seawater, subsea piping systems, heat exchangers, and more. For an alloy to be used in a marine environment, it must meet a decent required PREN value. Super Duplex UNS S32760 tape achieves a PREN or pitting resistance equivalent score of over 40. Scores over 38 indicate high resistance to pitting corrosion. Additionally, ASTM A240 UNS S32760 plate extends its high corrosion resistance to crevice corrosion and stress corrosion cracking, which are required for any alloy to survive in a marine environment. UNS S32760 Zeron 100 Sheet and Duplex Stainless Steel UNS S32760 Coil Can withstand high corrosion fatigue strength where industrial systems, press rollers, fans and shafts come in handy. Super duplex steel UNS S32760 strip is also used for mechanical components. Corrosion resistant systems in heat exchangers, high metal component constructions also use super duplex grade S32760 clad sheet as a lightweight cladding. SA 240 UNS S32760 sheet has a specific heat capacity of 466 J/kg-k and a melting range of 1400 to 1450 degrees Celsius. The average coefficient of thermal expansion between 20 and 400 degrees Celsius is 14. It is used in the nuclear industry and chemical plants due to the high temperature.