tubo acero inox duplex TP 304 S30400

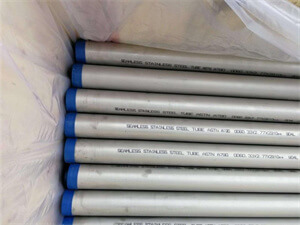

Stainless steel pipe is a hollow and longitude steel, economical steel section is circular. Stainless steel pipes have been widely used in petroleum, chemical, medical, food, light industry, equipment and structural parts, etc. Also, when torsional and torsional strength are equal, stainless steel is lighter, so it is used for equipment parts and project structures. It is also used to produce barrels and shells for various conventional weapons. This kind of pipe is divided into: stainless steel seamless pipe and stainless steel welded pipe.

ASTM A312 Standard Specification for Seamless, Welded, and Heavy-Duty Cold-Worked Austenitic Stainless Steel Pipe. Stainless steel pipes are widely used in sulfuric acid storage tanks in the phosphate fertilizer industry. Phosphoric acid units in fluosilicic acid reactors; chlorate crystallizers in fertilizer production; ventilation systems in pharmaceutical plants; solvent recovery filters, condensers, piping; bleaching equipment and filters in the pulp and paper industry; piping and Water collection system; multi-stage flash evaporation, low temperature multi-effect desalination; power plant seawater condenser, etc.

Known for its flexibility, grade 304 stainless steel is one of the most used alloys on the market. Stainless steel 304 pipe/tubing is widely used in industry to control varying nitrogen content. Stainless steel 304 pipe has high mechanical strength due to its dual phase microstructure.

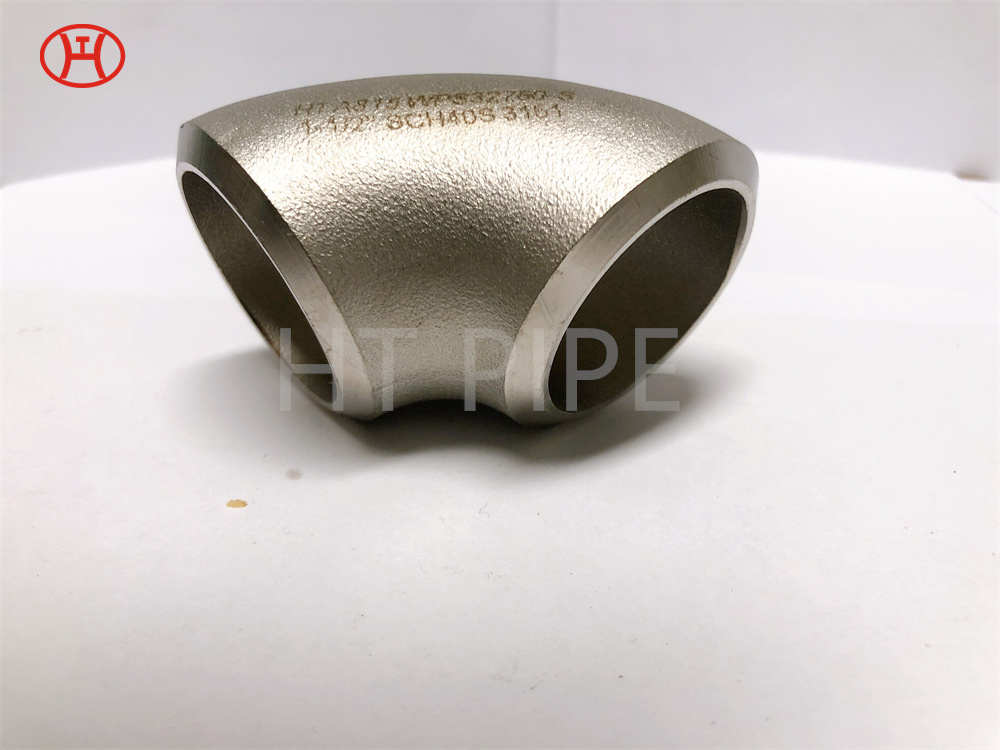

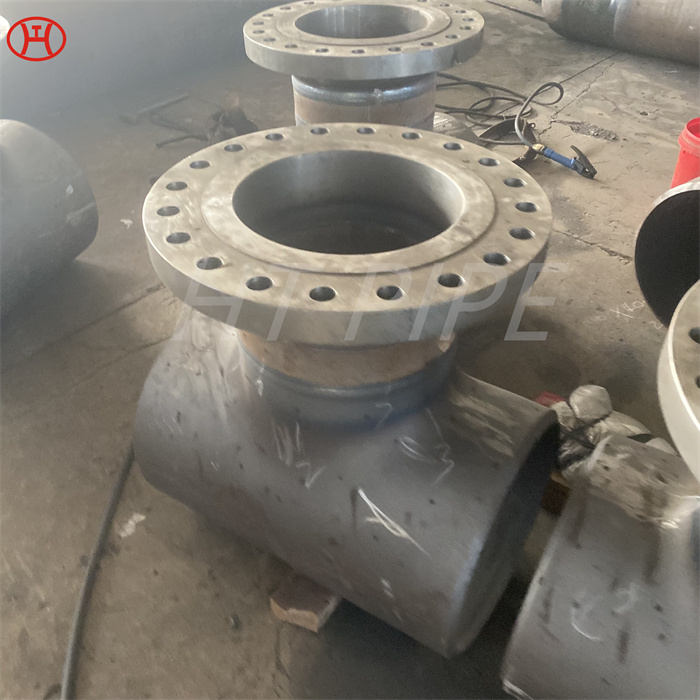

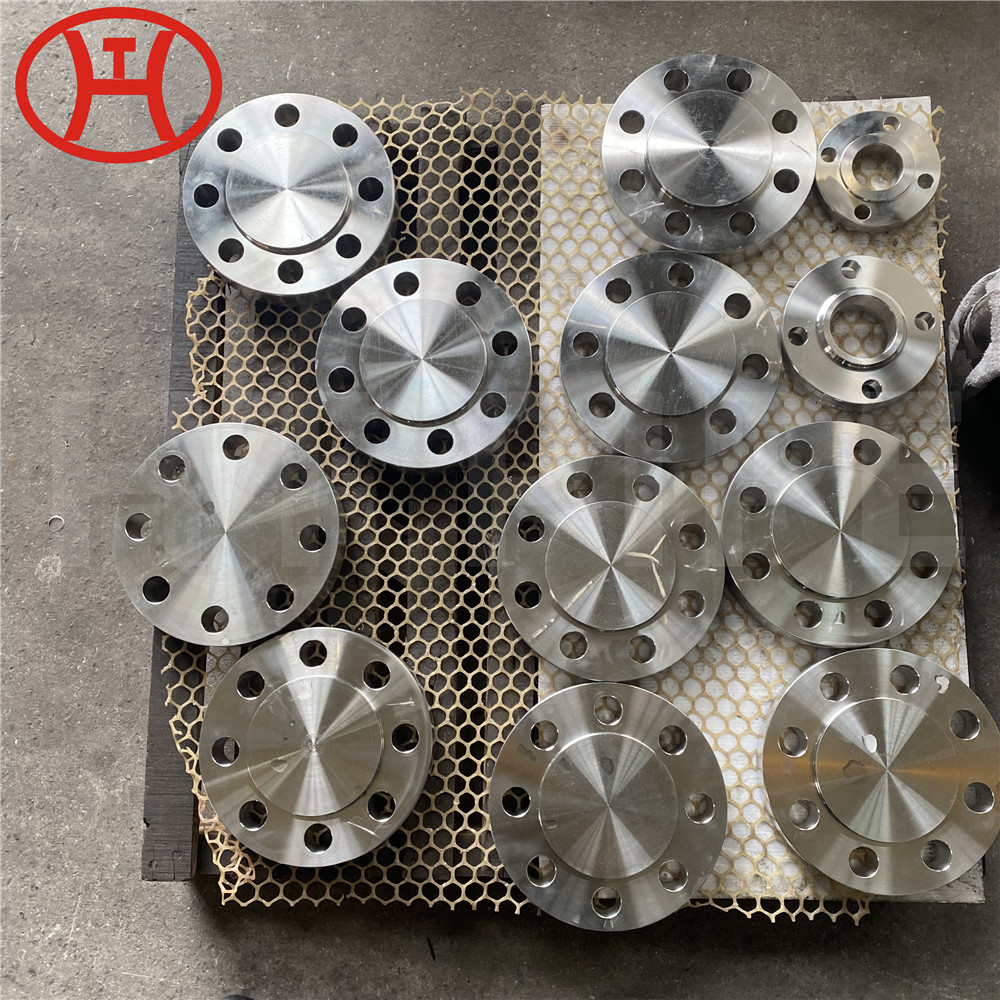

Stainless steel piping systems are the product of choice for conveying corrosive or sanitary fluids, slurries and gases, especially where high pressure, high temperature or corrosive environments are involved. Due to the aesthetic properties of stainless steel, pipes are often used in architectural applications.