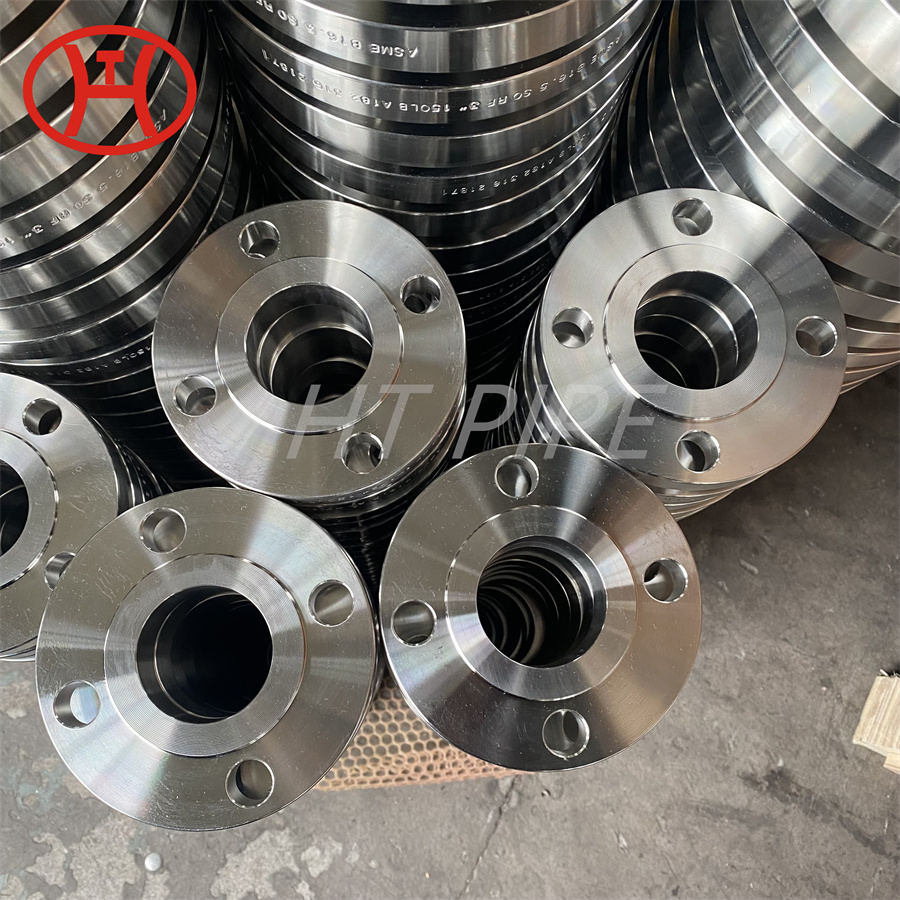

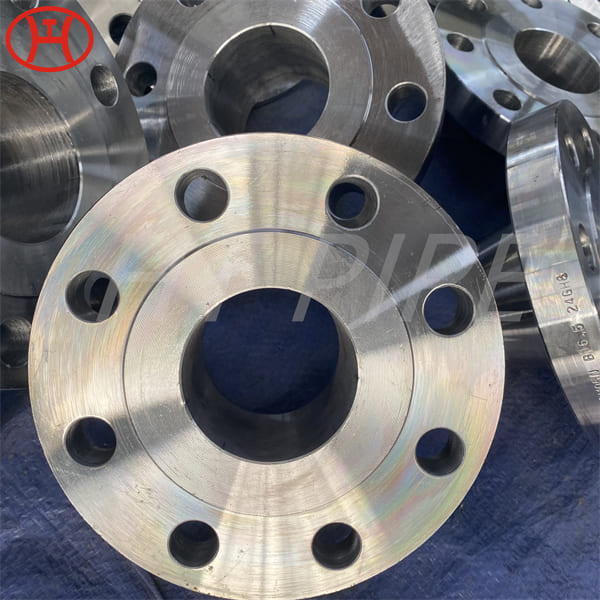

Alloy 31 W.Nr 1.4562 WN Flange Manufacturer

The addition of nitrogen provided the added benefits of improved localized corrosion resistance, stronger mechanical properties, and higher thermal stability.

Alloy 31 Flange, W.Nr 1.4562 WN Flange Manufacturer, ASME B16.5 Class 300 Flange Supplier, UNS N08031 Flange

Alloy 31, known as the “advanced 6 Mo alloy” is the higher-chromium-and—nickel version, and imparts significantly improved corrosion resistance in a variety of media. The localized corrosion resistance of Alloy 31 Flange is superior than many flanges, including the N i-Cr—Mo alloy 625 flange, as shown per ASTM G-48 testing. The uniform corrosion resistance in sulfuric acid of W.Nr 1.4562 WN Flange in the medium concentration range is superior to even that of Alloy C-276 and alloy 20. As a result, the 6Mo alloys Flanges have been applied extensively in pulp and paper production, phosphoric acid production, copper smelters, and sulfuric acid production / reclamation.

UNS N08031 Flange is also frequently selected for equipment in pollution control and in the production of phosphoric acid, rayon, and specialty chemicals. The resistance to salt water corrosion of W.Nr 1.4562 WN Flange has made it successful in marine and offshore applications, pickling baths, and heat exchangers for which seawater and brackish water act as coolants. One recent application of Alloy 31 Flange has been in the pressure acid leaching process of recovering nickel from the lateritic ore deposits in Australia. Many hundreds of tons of this alloy have been used in this technology.

| Chemical Composition | ||||||||||

| C | Si | Mn | P | S | Cr | Mo | Ni | N | Cu | Fe |

| 0.015Max | 0.3Max | 2.0Max | 0.02Max | 0.01Max | 26.0-28.0 | 6.0-7.0 | 30.0-32.0 | 0.15-0.25 | 1.0-1.4 | Balance |

| Mechanical Properties | |||||

| Tensile Strength, min. | Yield Strength, min. | Elongation, min. | Hardness, min | ||

| Mpa | ksi | Mpa | ksi | % | HB |

| 650 | 95 | 277 | 41 | 40 | 220 |