Carbon Steel Flange Weight ASME B16.5 CS Weld Neck Flange manufacturer

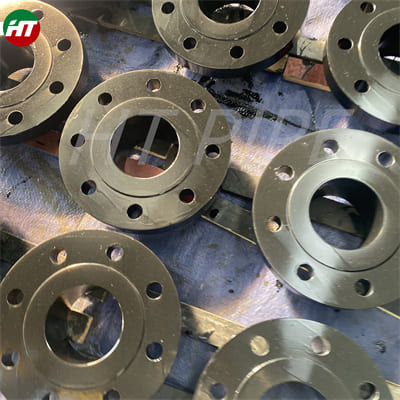

Flanges are an integral part of the process industry. Most industries, including oil and gas, water treatment, and nuclear power generation, use pipes that allow media to flow between different plant units. Components such as fittings and carbon steel SA105 pipe flanges help regulate the flow of said media.

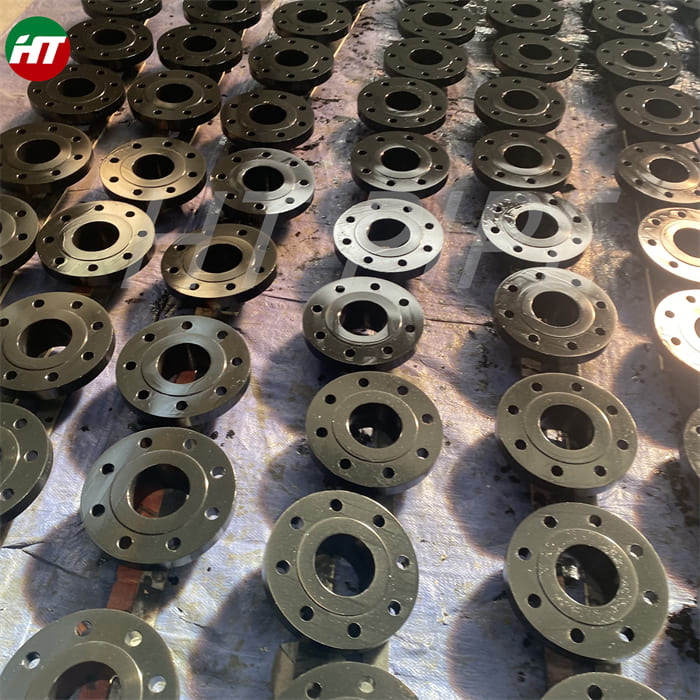

Carbon Steel Threaded Flange,Slip On Flanges, Plate Flange, RTJ Flange And WNRF Flange At Low Prices In China, Buy BS 4504 Carbon Steel Forged Flange at HT PIPE, ANSI B16.5 Carbon Steel Blind Flange, ANSI B16.48 Carbon Steel Long Weld Neck Flange At Factory Price In China, View Carbon Steel Flange Price List

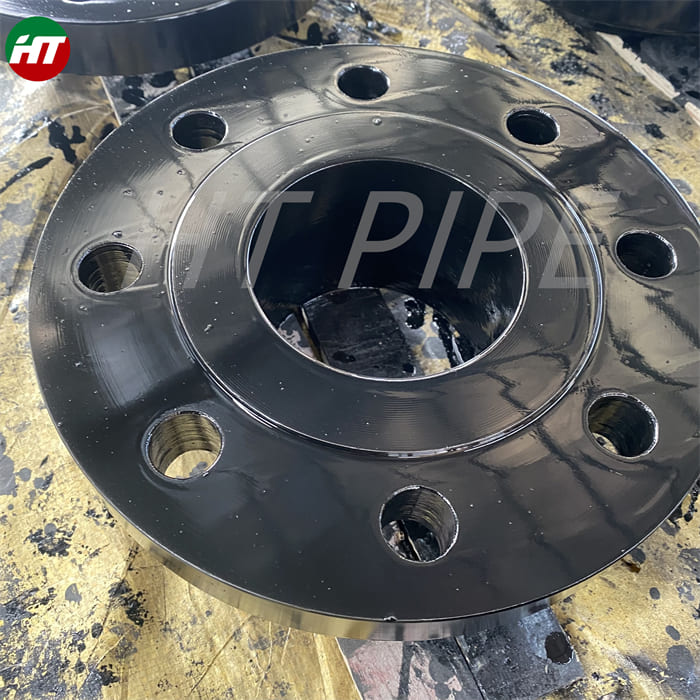

As compared to stainless steel grades, the carbon steel pipe flanges have a higher carbon content. This high content of carbon is what gives the carbon steel plate flanges a lower melting point. An increased carbon content in the cs slip on flanges makes them more malleable. Further, these Carbon Steel Forged Flanges have good durability and they offer better heat distribution properties.

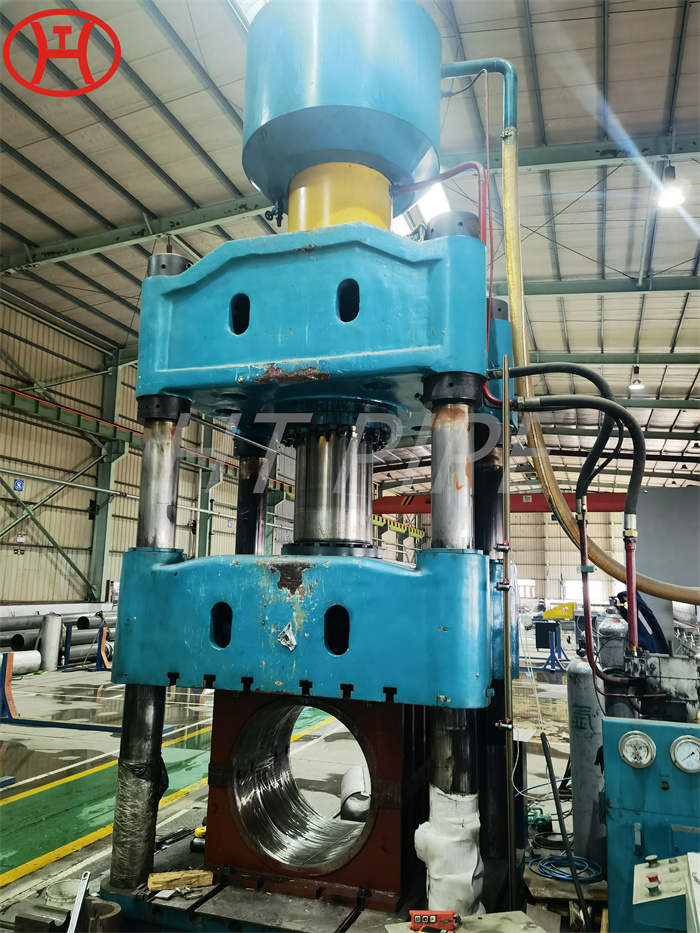

There is another type of flange that is known as killed Carbon Steel Forged Flanges. They are destroyed in the melting process. Due to the addition of manganese, silicon, and aluminum during the production of steel, deoxidation takes place. Carbon Steel Plate Flanges are welded onto the pipe which helps in bolting and connecting one pipe to the other. It displays good ductility, and toughness. These Carbon Steel Pipe Flanges also work well in low temperatures. They are used in fuel and water pipelines. The cost of these Carbon Steel Forged Flanges ranges between Rs 398 to Rs 689.

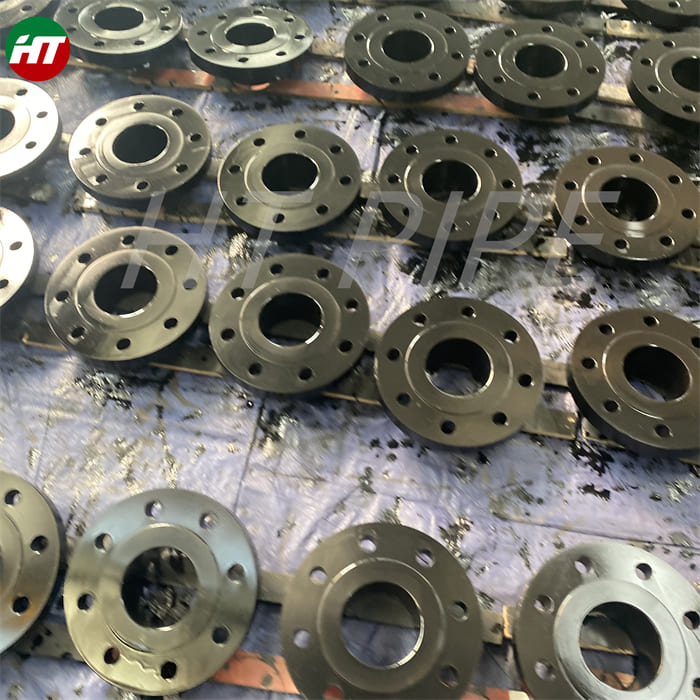

To strengthen and harden the steel and cast iron alloy Carbon Steel Slip On Flanges are passed through a process known as quenching. They are used in various construction, engineering, and petrochemical industries. The outer diameter of the slip on flange is also welded. Carbon Steel Weld Neck Flanges have a neck extension at the end. This type of flange is directly buttwelded to the pipe to provide a natural connection. Carbon Steel Flanges manufacturers in China recommend the use of these flanges when the conditions are critical and severe.

| A105 Carbon Steel Flange Types | Size | |

| Carbon Steel Slip-On Flanges | Carbon Steel Weld Neck Flanges | Sizes 1/2″ – 48″ Raised Face or Flat Face |

| Carbon Steel Threaded Flanges | Carbon Steel Socket Weld Flanges | |

| Carbon Steel Plate Flanges | Carbon Steel Reducing Flanges | |

| Carbon Steel Lap Joint Flanges | Carbon Steel Blind Flanges | |

| Carbon Steel Square Flanges | Carbon Steel Ring Type Joint Flanges | |

| Carbon Steel Forged Flanges | Carbon Steel Orifice Flanges | |