Stainless steel 304 304l S30403 pipes AISI 304 Pipes Manufacturers

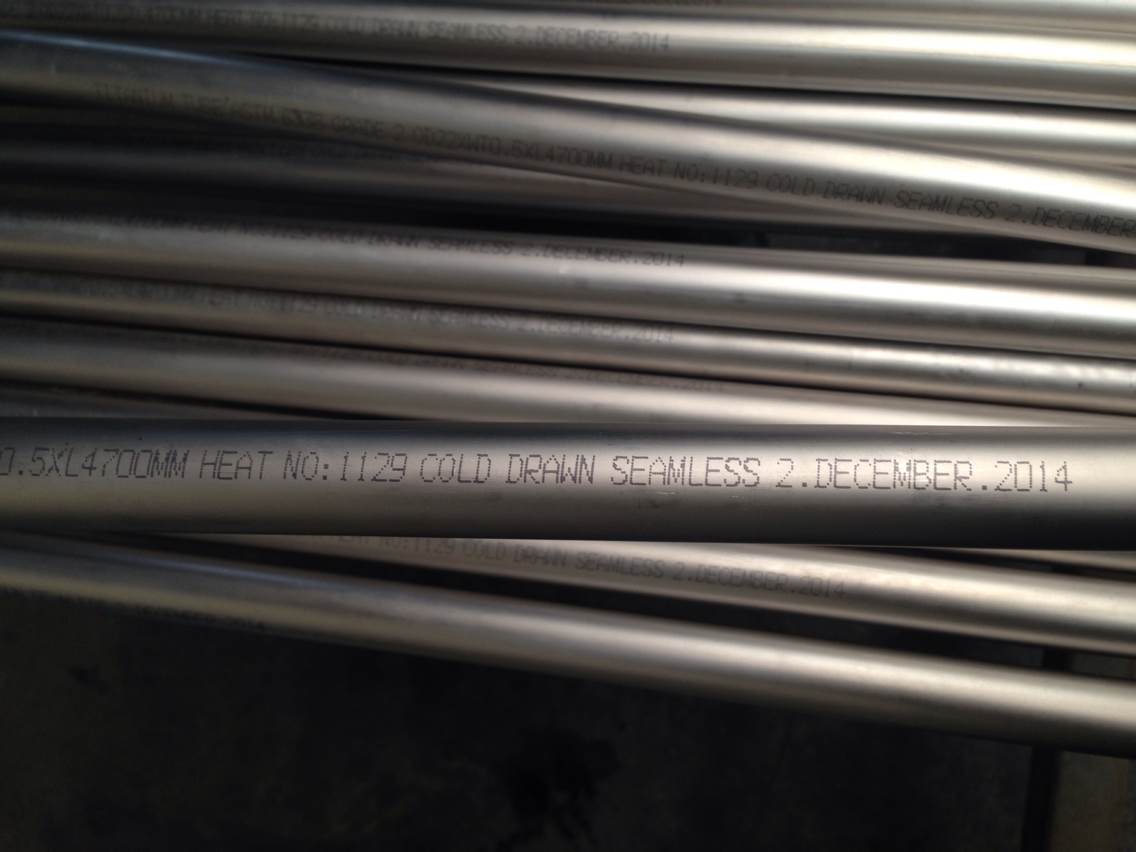

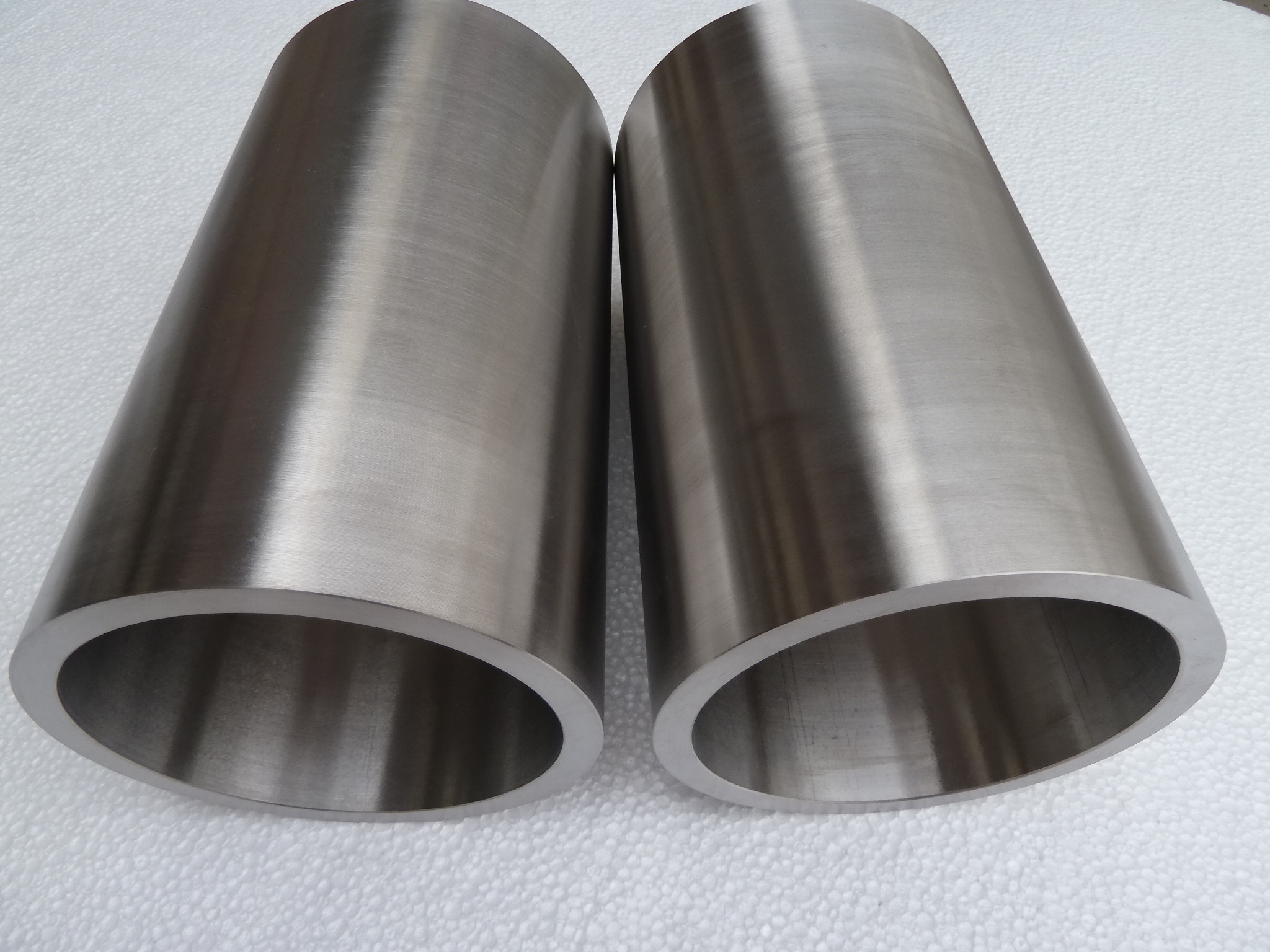

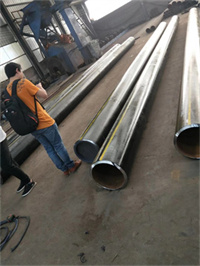

Stainless steel pipes are long, hollow tubes that are used for a wide range of industrial applications. They are produced by two distinct methods which result in either a welded or seamless pipe. Alloy 304 stainless steel pipe provides enhanced strength and corrosion resistance and can be used for all types of fabrication processes, especially those that are subjected to outdoor environmental conditions.

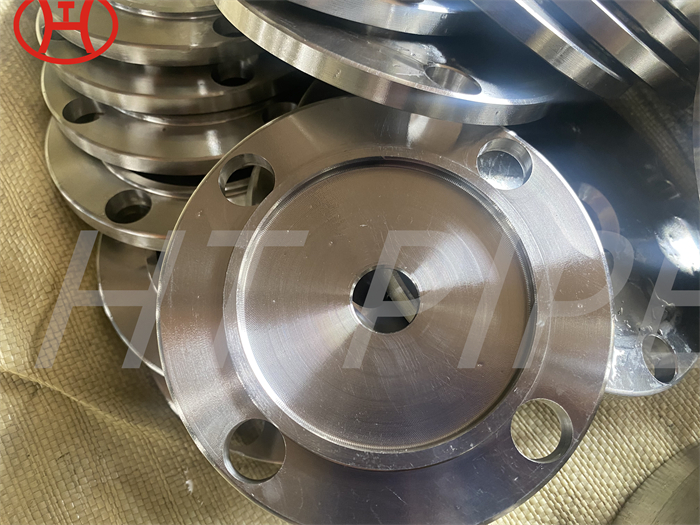

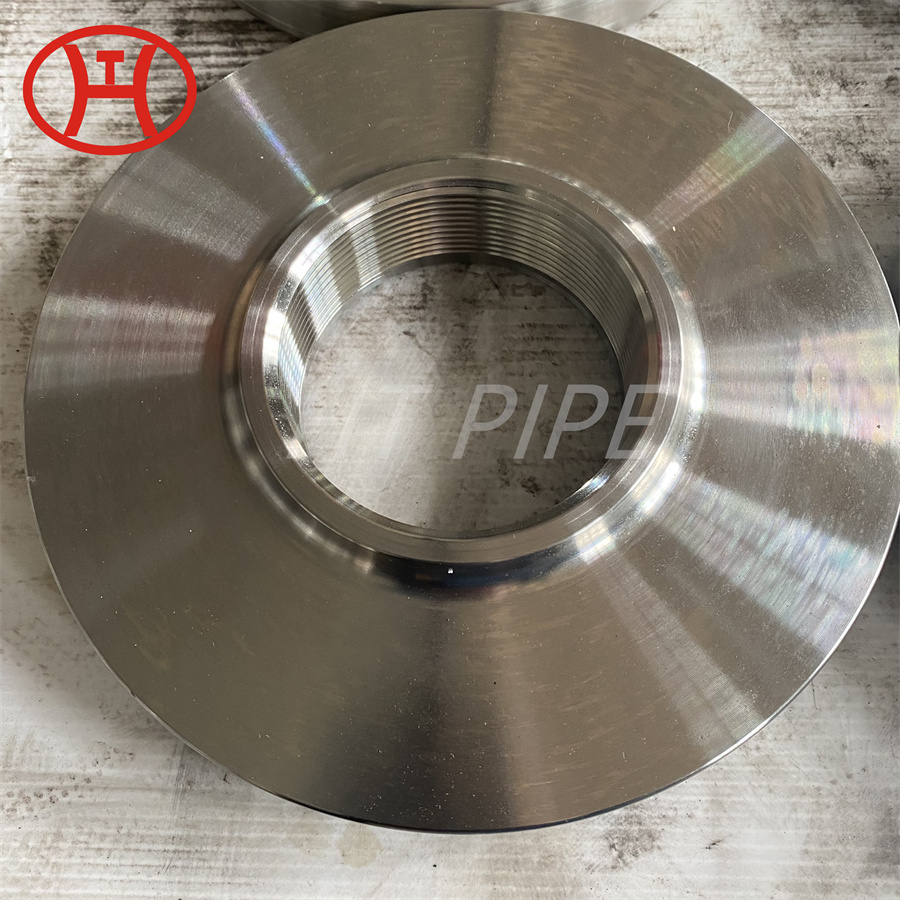

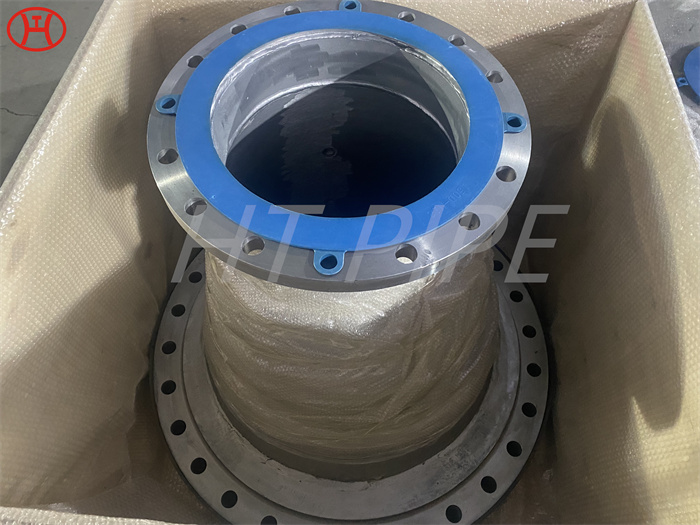

HT PIPE supplies stainless steel 304 pipes as well as stainless steel 304 fittings and stainless steel 304 flanges. Given our extensive expertise and knowledge in stainless steel industry we can offer stainless steel 304 pipes, at the most competitive prices in the Industry. We are Wholesaler for stainless, acid and heat-resistant steel pipes, fittings and flanges with extensive stocks.

304 stainless steel pipe is a metal grade that is highly resistant to corrosion, intergranular corrosion and moderately corrosive organic acids. This is possible because it is an 18/8 steel, which means it has been alloyed with 18% chromium and 8% nickel. In some cases, the corrosion rate of 304L steel is lower than that of 304 alloy. However, 304L, 304 and 304H exhibited consistent performance when placed in corrosive environments. ASTM A312 Tp304l Stainless Steel Pipe is one of the most widely used steel pipes in the world for many reasons. ASTM A312 Gr Tp304l is less expensive than most other stainless steel products and therefore cost effective. It is an austenitic stainless steel with chromium in it. 304L has good heat resistance. Compared to 304 alloy, it has higher resistance to carbide precipitation, allowing it to be used continuously at temperatures between 800 and 1580 degrees Fahrenheit.

304 stainless steel pipe is highly resistant to corrosion, intergranular corrosion and moderately corrosive organic acids. This is possible because food grade stainless steel pipe is an 18/8 steel, which means it has been alloyed with 18% chromium and 8% nickel. In some cases, the corrosion rate of 304L steel is lower than that of 304 alloy. However, 304L, 304 and 304H exhibited consistent performance when placed in corrosive environments. ASTM A312 Tp304l Stainless Steel Pipe is one of the most widely used steel pipes in the world for many reasons. ASTM A312 Gr Tp304l is less expensive than most other stainless steel products and therefore cost effective. It is an austenitic stainless steel with chromium in it. 304L has good heat resistance. Compared to 304 alloy, it has higher resistance to carbide precipitation, allowing it to be used continuously at temperatures between 800 and 1580 degrees Fahrenheit.

304/304L/304H Stainless Steel Pipes, Tube Chemical Composition

| Chemical Composition % | ||||||||

| C | Mn | Si | P | S | Cr | Ni | Fe | |

| 304 | 0.08 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 10.5 | Balance |

| 304L | 0.03 max. | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 12.0 | Balance |

| 304H | 0.04-0.10 | 2.00 max. | 1.00 max. | 0.045 max. | 0.03 max. | 18.0 – 20.0 | 8.0 – 12.0 | Balance |

304/304L/304H Stainless Steel Pipes, Tube Mechanical Properties

| 304 | 304L | 304H | |

| Density | 8 | 8 | 8 |

| Melting Range,℃ | 1400 ℃ | 1400 ℃ | 1400 ℃ |

| Elongation % | 40 | 40 | 40 |

| Tensile Strength (Mpa) | 515 | 485 | 515 |

| Yield Strength (Mpa) | 205 | 170 | 205 |

| Hardness (Brinell) | 201 | 201 | 201 |