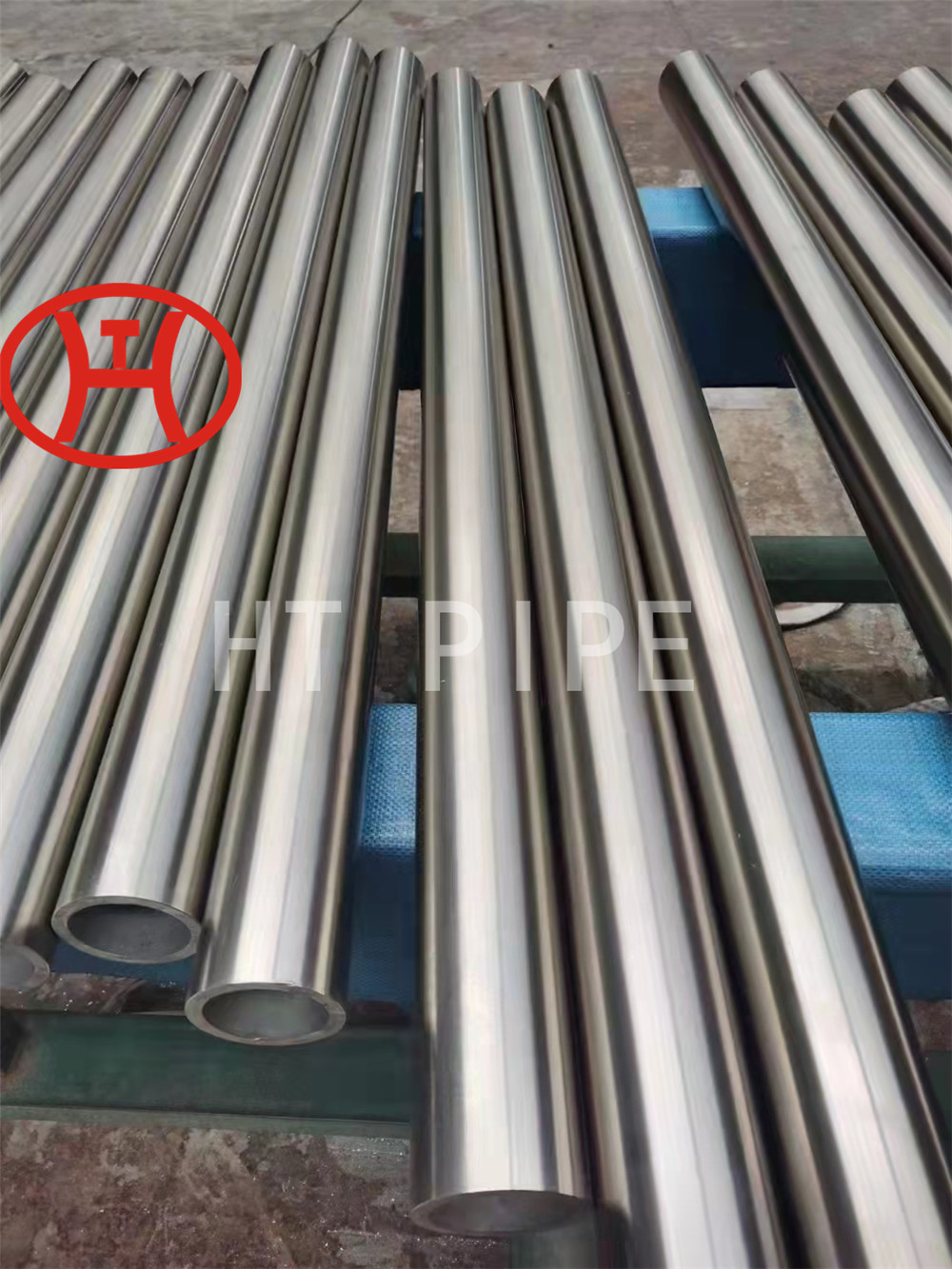

Stainless steel pipes and tubes of 254smo X1CrNiMoCuN20-18-7

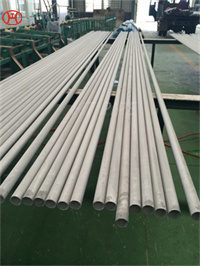

SMO 254 tube is highly alloyed and has corrosion resistance comparable to high performance austenitic steels. SMO 254 seamless pipe does not corrode, rust or get wet like regular steel.

Distributor, Stockist and Stockholder of UNS S31254, WNR 1.4529, EN 1.4547, 6 Mo Tubes

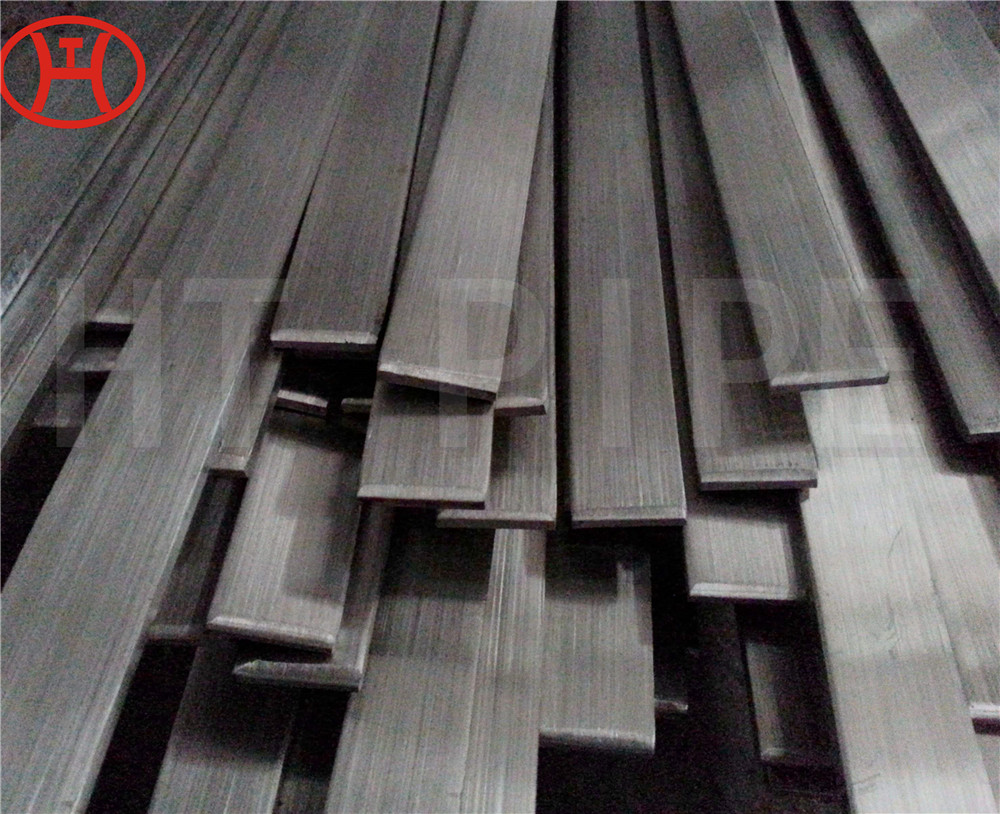

Alloy 254/254 SMO/6 Mo is an austenitic stainless steel with a high molybdenum content. Combined with nickel and copper, this gives the UNS S31254 tube good resistance to pitting and crevice corrosion, especially in environments containing halides such as chloride, bromide and fluoride solutions. 254 SMO (UNS S31254) provides a cost-effective solution for nickel and titanium alloys in these environments. SMO 254 EFW tube is available in a variety of shapes, sizes and surface finishes to suit the alloy environment it must withstand. These SMO 254 welded pipes are used to produce a chemical composition that produces a roughly equal mixture of ferrite and austenite.

UNS S31254 pipe provides chloride resistance that is superior as compared to alloy 904L, alloy 20, alloy 825 and alloy G. the metal is compatible with austenitic stainless steels and is used also as an replacement in critical components In the construction where the type 316L has not stood up to the mark, the SMO 254 welded pipe has been found to be adequate, and the prices are affordable. WNR 1.4529 stainless steel pipe comes with high resistance to the crevice, pitting and general corrosion and has very high resistance to chloride stress corrosion cracking. EN 1.4547 stainless steel pipe has excellent impact toughness along with workability and weldability.

Alloy 254 SMO is used in particular in areas requiring resistance to chlorinated seawater, as well as in flue gas cleaning, maritime exhaust gas cleaning (EGC), bleaching plants in the pulp and paper industry and in the chemical industry. SMO 254 is also widely used for seawater applications like cooling water pipes, cooling seawater, ballast water systems, and systems fighting the fire. 6 Mo Tubes are also widely seen in components in gas cleaning systems. One can see its applications in desalination equipment, food processing equipment, chemical processing equipment, pulp mill bleach systems and many more related to heavy industries. Due to their availability from the Alloy 254 UNS S31254 manufacturers in various forms like pipe fittings, tube fittings, flanges, seamless pipes and tubes, their application gets wider and can be seen in a wide range of industries.

Chemical Composition of SMO 254 Stainless Steel Pipes and Tubes

| C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu |

| ≤0.020 | ≤0.80 | ≤1.00 | ≤0.030 | ≤0.010 | 20 | 18 | 6.1 | 0.20 | 0.7 |

Mechanical Properties of SMO 254 Stainless Steel Pipes and Tube

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength | 680 MPa | 98600 psi |

| Yield strength | 300 MPa | 43500 psi |

| Modulus of elasticity | 195 GPa | 28300 ksi |

| Shear modulus | 75 GPa | 10900 ksi |

| Poisson’s ratio | 0.30 | 0.30 |

| Elongation at break | 50% | 50% |

| Hardness, Brinell | 210 | 210 |