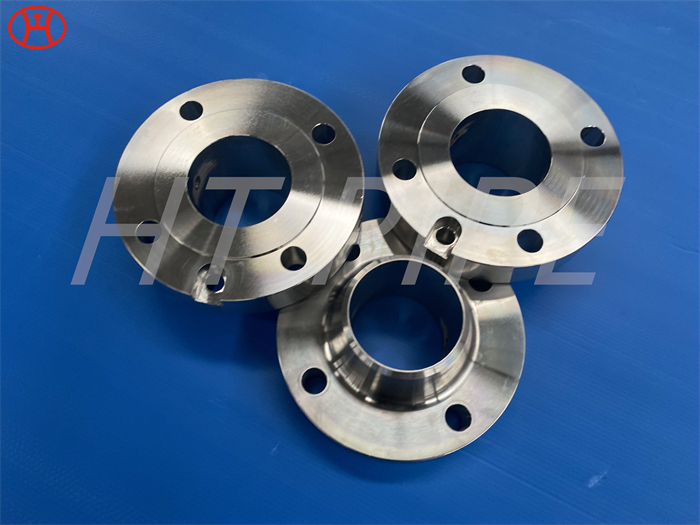

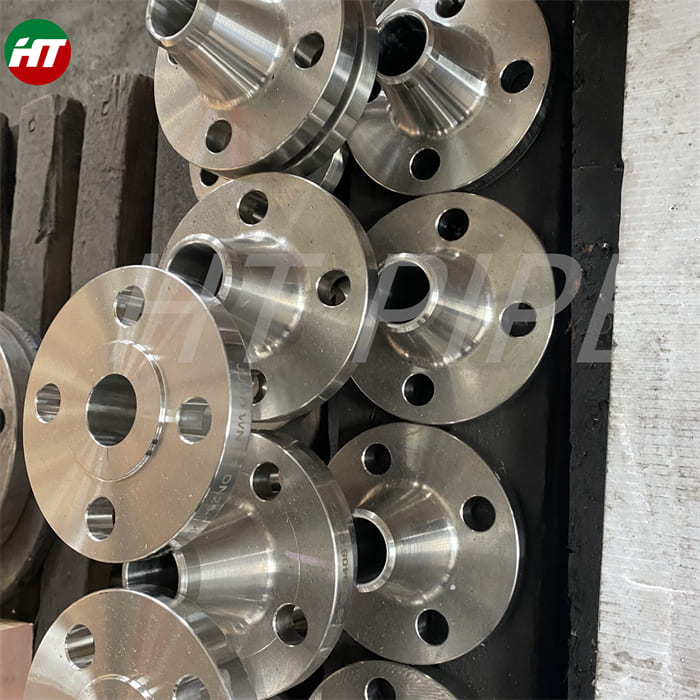

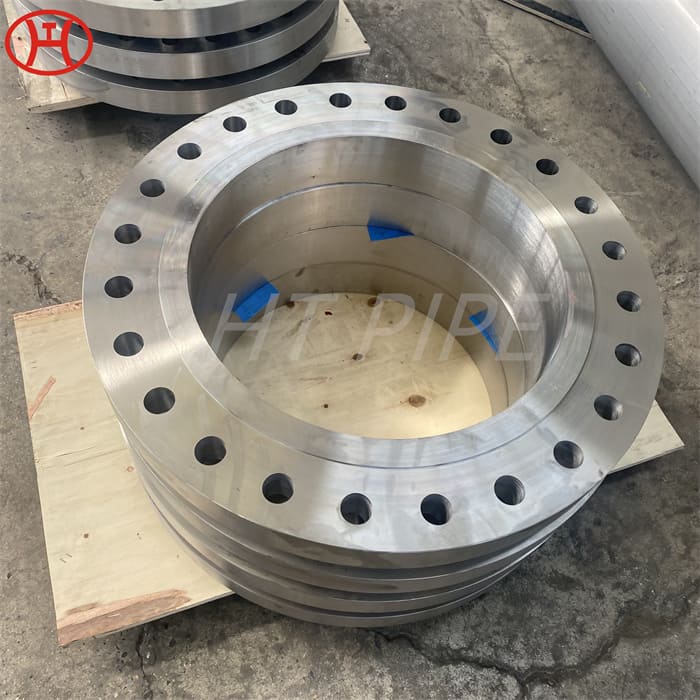

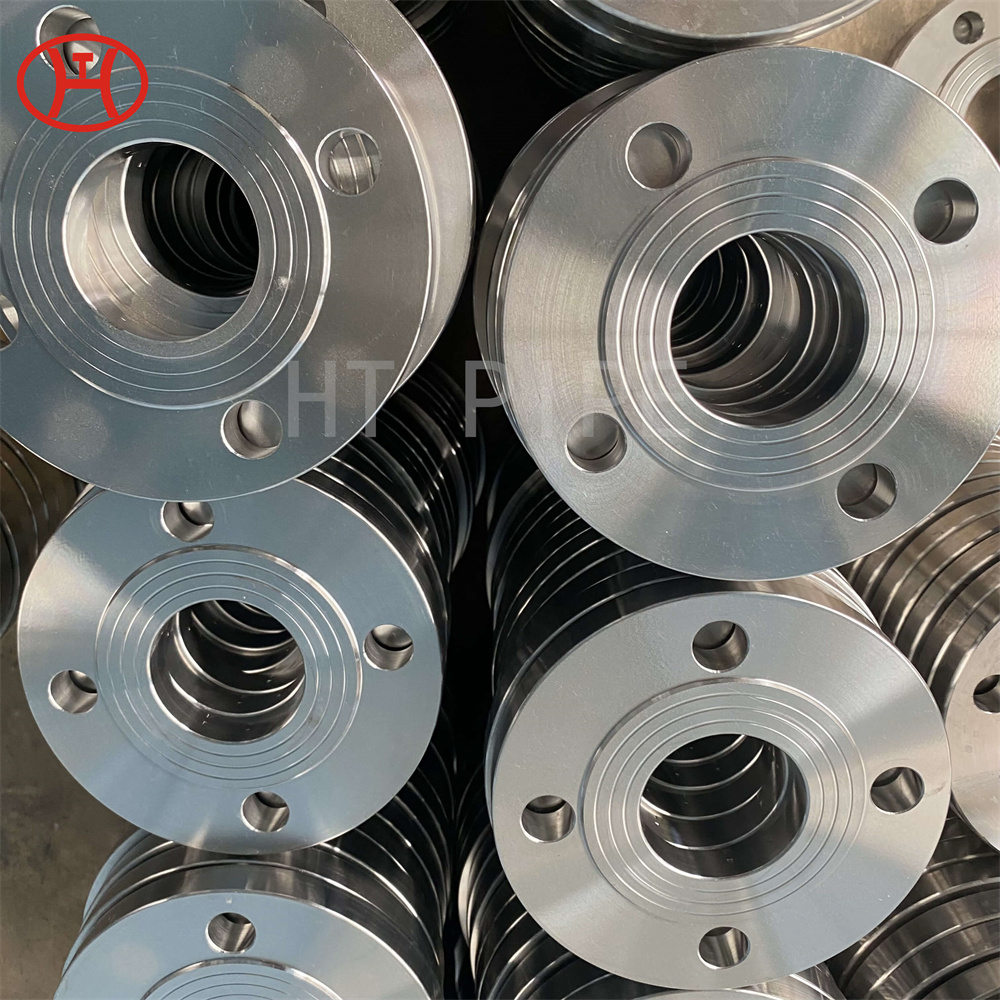

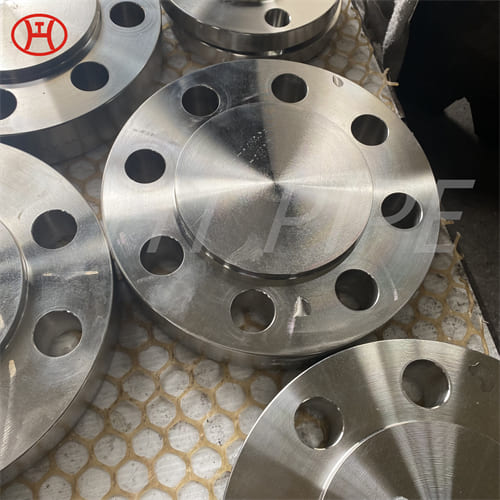

ASTM A182 904L 1.4539 Ansi Stainless Steel Flange

Our UNS N08904 Stainless Steel Blind Flanges are widely used to close the tail of pipe of a pressure vessel, as they are designed to retain pressure in a high-pressure area, and are resistant to reducing acids like sulphuric acids in petrochemical plants and oil refineries.

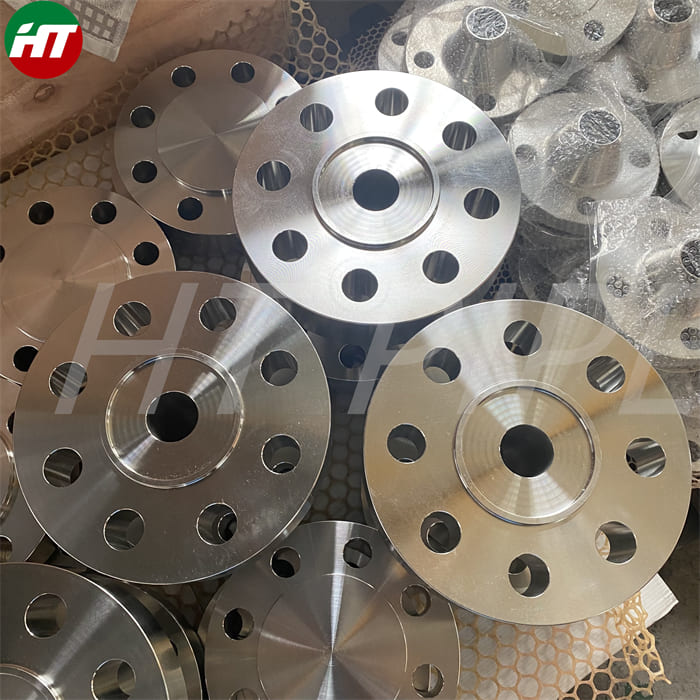

ASTM B366 Stainless Steel 904L Flanges Suppliers, SS 904L flanges, SS 904L SO flanges, SS 904L weld neck flanges, SS 904L blind flanges & SS 904L flat face flanges stockholders

SS 904L Flanges are made up of a nickel chromium austenitic stainless steel which has 23% nickel and 19% chromium minimum in the composition with carbon, manganese, silicon, phosphorus, sulfur, copper and 4% molybdenum to it. The nickel chromium molybdenum composition provides the Alloy 904L flange with excellent corrosion resistance and strength. ASME SA182 SS 904L flange also has good mechanical properties such as 220MPa minimum yield strength and 490MPa minimum tensile strength. The melting point of the SS DIN 1.4539 flange is also high at 1350 degrees Celsius. The Alloy 904L Blind Flange is used at the end of a pipe to close it, mostly permanently. The 150# ANSI SS 904L flange is a low carbon version of the 904 grade of steel. This means welding and forming operations are easy on these SS 904L Plate Flanges without risking grain formation and intergranular corrosion due to the carbide precipitation while welding.

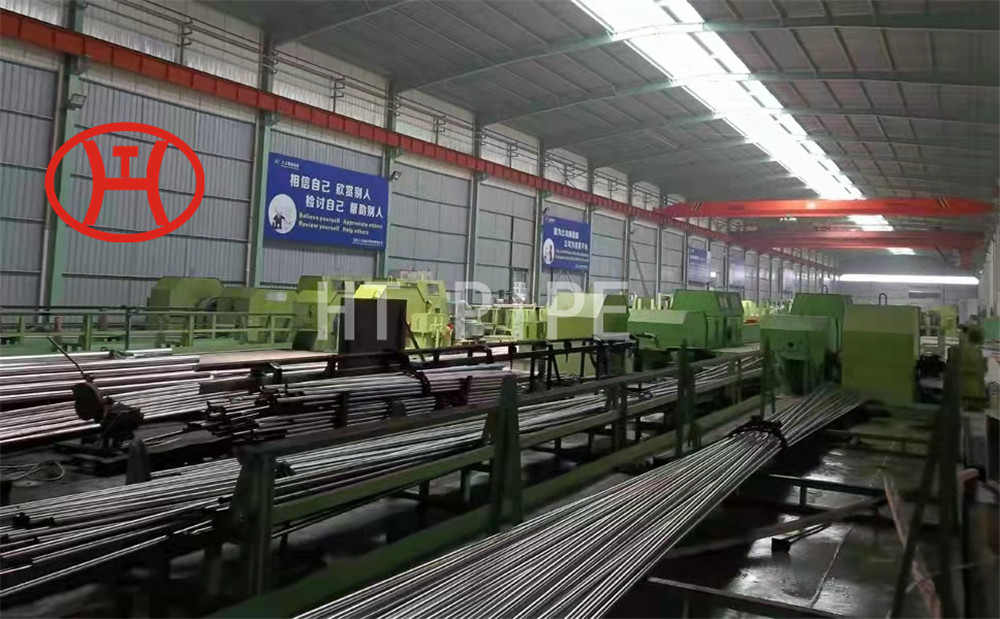

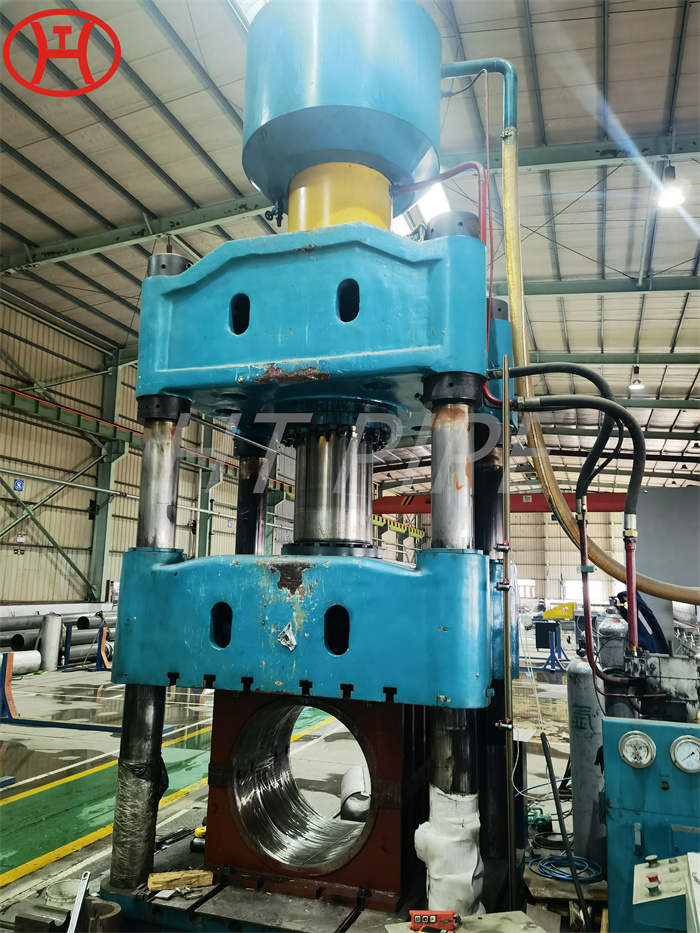

HT PIPE is prominent supplier & manufacturer of ASTM A182 F904L Stainless Steel Flanges, thereby adopting standards and processes that are secure, quality-driven and assure maximum output.Our offered ASME B16.47 347 Slip On Flange stand by the principles of quality and safety. 904L Stainless steel Flange is combination of nickel content of the material, with a nickel content of 25 %, Stainless Steel 904L Flanges has proven to be a good alternative to most conventional stainless steels. In Grade 904L Stainless Steel Pipe flange has good resistance. UNS N08904 Flange can be easily welded and processed by standard shop fabrication practices. A182 F904L Flange working temperatures is 1562 Degree F – 2102 Degree F (850 Degree C – 1150 Degree C).

ASTM A182 Grade 904L Stainless Steel Flanges

| Grade | SS 904L |

| Stainless Steel 904L Flanges Standard : | ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges |

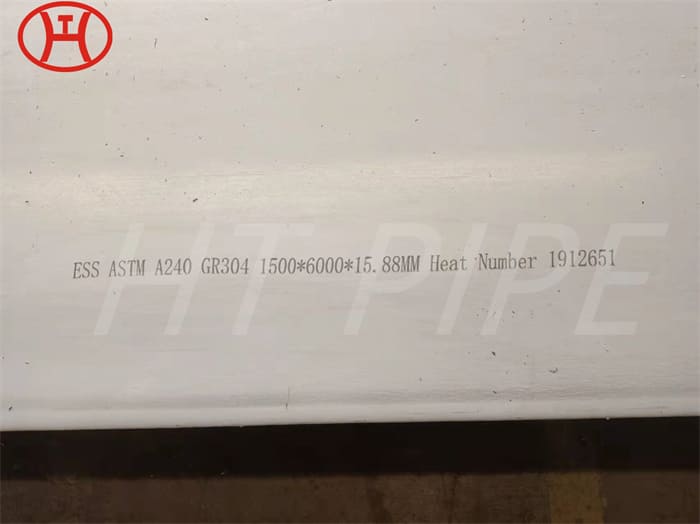

| Specification : | ASTM B366 |

| Dimension : | ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN |

| Stainless Steel 904L Flanges Class : | 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 |

| Size : | 1/8″ to 36″ |

| Test Certificate | EN 10204-3.1, EN 10204-3.2 |

| Under Third Party Inspection | |

| Items | Forged Flanges: SORF, WNRF, BLRF, SWRF, LAP Joint, Threaded, Reducing |

| Plate Flanges: SORF, BLRF, LAP Joint & Spectacle | |

| Pipe fitting surplus stock at Dynamic Forge & Fittings | Pipe Fittings |

| Butt Weld Fittings | |

| Forged Fittings | |

| Socket Weld Fittings | |

| Threaded Fittings | |

| Flange | |

| Specialize | As per drawing |

| SS Grades | 304, 304L, 304H, 316, 316L, 316LN, 316Ti, 309, 310S, 317L, 321, 347, 410, 420, 440C, 904L etc. |

| Also as per National & International Standard & Specification | |